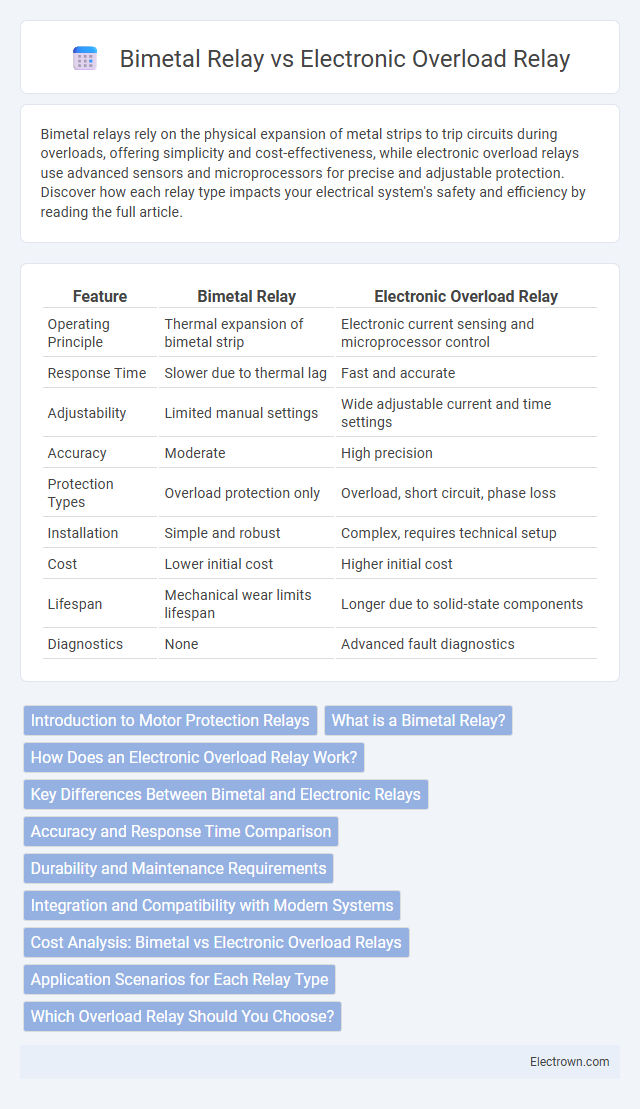

Bimetal relays rely on the physical expansion of metal strips to trip circuits during overloads, offering simplicity and cost-effectiveness, while electronic overload relays use advanced sensors and microprocessors for precise and adjustable protection. Discover how each relay type impacts your electrical system's safety and efficiency by reading the full article.

Table of Comparison

| Feature | Bimetal Relay | Electronic Overload Relay |

|---|---|---|

| Operating Principle | Thermal expansion of bimetal strip | Electronic current sensing and microprocessor control |

| Response Time | Slower due to thermal lag | Fast and accurate |

| Adjustability | Limited manual settings | Wide adjustable current and time settings |

| Accuracy | Moderate | High precision |

| Protection Types | Overload protection only | Overload, short circuit, phase loss |

| Installation | Simple and robust | Complex, requires technical setup |

| Cost | Lower initial cost | Higher initial cost |

| Lifespan | Mechanical wear limits lifespan | Longer due to solid-state components |

| Diagnostics | None | Advanced fault diagnostics |

Introduction to Motor Protection Relays

Motor protection relays are essential devices designed to safeguard electric motors from damage caused by overloads, short circuits, and phase failures. Bimetal relays utilize a temperature-sensitive bimetal strip that bends under excessive current heat to break the circuit, providing a simple and cost-effective overload protection. Electronic overload relays employ solid-state components and microprocessors to offer precise motor protection, adjustable settings, and faster response times compared to traditional bimetal relays.

What is a Bimetal Relay?

A Bimetal Relay is a thermal protection device that uses two different metals bonded together, expanding at different rates when heated to trip the relay and protect electrical circuits from overloads. Unlike electronic overload relays, which use sensors and microprocessors, bimetal relays operate purely on thermal expansion, providing a simple and cost-effective solution for motor protection. Your choice between the two depends on the required accuracy, response time, and application environment.

How Does an Electronic Overload Relay Work?

An electronic overload relay protects motors by continuously monitoring current flow and detecting overload conditions through advanced sensors and microprocessor-based algorithms. It measures real-time electrical parameters such as current, voltage, and temperature, instantly triggering a trip when abnormal values indicate potential damage. Unlike bimetal relays, electronic overload relays offer precise adjustable settings, faster response times, and enhanced diagnostic functions for improved motor protection.

Key Differences Between Bimetal and Electronic Relays

Bimetal relays rely on thermal expansion of a metal strip to interrupt current, offering simplicity and reliability but slower response times and limited precision. Electronic overload relays utilize solid-state components and sensors to provide faster, more accurate trip settings with advanced features like adjustable current sensitivity and communication capabilities. Unlike bimetal designs, electronic relays enable integration into smart motor control systems, improving protection efficiency and reducing downtime.

Accuracy and Response Time Comparison

Bimetal relays rely on thermal expansion to trip, resulting in slower response times typically ranging from seconds to minutes, whereas electronic overload relays use solid-state components to detect overcurrent conditions with millisecond precision. Electronic overload relays offer higher accuracy through adjustable settings and diagnostic features that reduce false trips and enhance protection reliability. Your choice between the two will impact system sensitivity and downtime, especially in applications requiring fast and precise overload detection.

Durability and Maintenance Requirements

Bimetal relays offer robust durability due to their simple mechanical design, making them less susceptible to electrical noise and voltage spikes, which translates to lower maintenance requirements over time. Electronic overload relays provide precise and adjustable protection settings but may require periodic calibration and can be more sensitive to environmental factors like temperature and humidity, potentially increasing maintenance needs. Evaluating your operational environment and maintenance capabilities is essential to choose the right relay for long-term reliability and performance.

Integration and Compatibility with Modern Systems

Bimetal relays offer basic overload protection but lack seamless integration with modern control systems due to their mechanical nature and limited communication capabilities. Electronic overload relays provide advanced features such as programmable settings, digital communication protocols like Modbus or Ethernet/IP, and remote monitoring, ensuring compatibility with Industry 4.0 environments. These attributes make electronic overload relays more suitable for smart automation systems requiring precise control and real-time data exchange.

Cost Analysis: Bimetal vs Electronic Overload Relays

Bimetal relays typically offer lower upfront costs compared to electronic overload relays, making them an economical choice for basic motor protection. Electronic overload relays, while more expensive initially, provide advanced features such as precise current sensing, faster response times, and adjustable trip settings that can reduce maintenance expenses and downtime over time. Your investment in electronic overload relays may yield better long-term savings through enhanced protection and energy efficiency despite the higher initial price.

Application Scenarios for Each Relay Type

Bimetal relays are widely used in applications requiring simple, reliable thermal protection, such as small motors in HVAC systems, compressors, and pumps, where cost-effectiveness and basic overheating protection are critical. Electronic overload relays excel in industrial environments with complex motor control needs, offering precise current measurement, adjustable trip settings, and integration with automation systems for applications like conveyor belts, large motors, and variable frequency drives. Your choice depends on whether you prioritize basic thermal protection or advanced monitoring and control capabilities.

Which Overload Relay Should You Choose?

Bimetal relays offer cost-effective and reliable protection for motors with simple thermal trip mechanisms, making them suitable for small to medium applications with predictable load conditions. Electronic overload relays provide precise adjustable settings, fast response times, and advanced diagnostics, ideal for complex or variable load environments requiring enhanced motor protection. Your choice depends on the application's complexity, budget, and need for diagnostic features, with electronic relays favored in modern industrial systems and bimetal relays in straightforward, budget-conscious scenarios.

Bimetal Relay vs Electronic Overload Relay Infographic

electrown.com

electrown.com