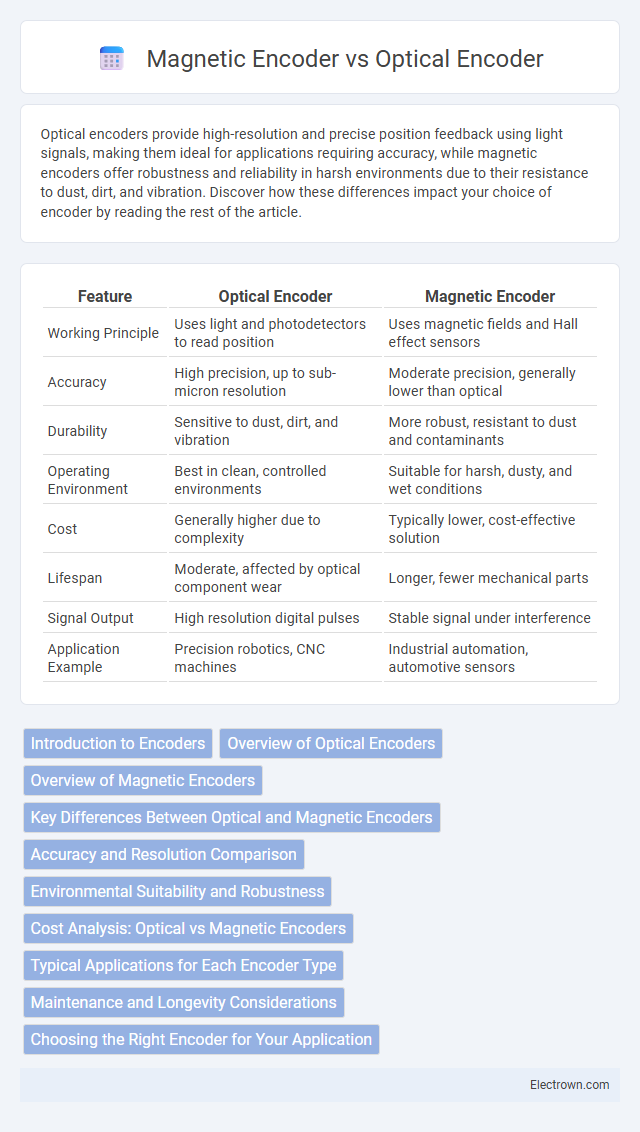

Optical encoders provide high-resolution and precise position feedback using light signals, making them ideal for applications requiring accuracy, while magnetic encoders offer robustness and reliability in harsh environments due to their resistance to dust, dirt, and vibration. Discover how these differences impact your choice of encoder by reading the rest of the article.

Table of Comparison

| Feature | Optical Encoder | Magnetic Encoder |

|---|---|---|

| Working Principle | Uses light and photodetectors to read position | Uses magnetic fields and Hall effect sensors |

| Accuracy | High precision, up to sub-micron resolution | Moderate precision, generally lower than optical |

| Durability | Sensitive to dust, dirt, and vibration | More robust, resistant to dust and contaminants |

| Operating Environment | Best in clean, controlled environments | Suitable for harsh, dusty, and wet conditions |

| Cost | Generally higher due to complexity | Typically lower, cost-effective solution |

| Lifespan | Moderate, affected by optical component wear | Longer, fewer mechanical parts |

| Signal Output | High resolution digital pulses | Stable signal under interference |

| Application Example | Precision robotics, CNC machines | Industrial automation, automotive sensors |

Introduction to Encoders

Optical encoders utilize light and photodetectors to convert motion into electrical signals, offering high resolution and precision in position sensing. Magnetic encoders rely on magnetic fields detected by Hall effect sensors or magnetoresistive elements, providing robustness in harsh environments with immunity to dust, dirt, and vibrations. Both encoder types serve critical roles in applications requiring accurate motion control, but their differing sensing mechanisms suit diverse operational conditions and system requirements.

Overview of Optical Encoders

Optical encoders use a light source, photodetector, and a coded disk to convert angular position or motion into an electrical signal with high precision and resolution. This technology excels in applications requiring accurate feedback, such as robotics, CNC machinery, and industrial automation, due to its resistance to noise and ability to deliver precise position data. Your choice of encoder depends on the required accuracy, environmental conditions, and application needs, with optical encoders often preferred for clean environments demanding fine resolution.

Overview of Magnetic Encoders

Magnetic encoders utilize magnetic fields to detect rotational position through a sensor and a magnet attached to the rotating shaft, offering high durability in harsh environments. Their non-contact nature minimizes wear and tear, making them more reliable for industrial applications with dust, moisture, or vibration. You can benefit from their compact design and immunity to dirt, which often challenges optical encoders reliant on light-based detection methods.

Key Differences Between Optical and Magnetic Encoders

Optical encoders use light and photodetectors to measure position with high resolution and accuracy, making them ideal for precision applications. Magnetic encoders rely on magnetic fields and sensors such as Hall effect sensors, offering robust performance in harsh environments with resistance to dust, dirt, and vibration. Key differences include optical encoders' sensitivity to contaminants but superior precision, while magnetic encoders provide durability and lower maintenance at a slightly reduced resolution.

Accuracy and Resolution Comparison

Optical encoders typically provide higher accuracy and resolution, often reaching up to 20,000 counts per revolution due to precise light-based detection methods. Magnetic encoders, with resolutions commonly ranging from 100 to 4,000 counts per revolution, offer robust performance in harsh environments but generally have lower accuracy compared to optical types. The choice between optical and magnetic encoders depends on the required precision and environmental conditions, with optical encoders favored for high-resolution applications and magnetic encoders preferred for durability and resistance to contaminants.

Environmental Suitability and Robustness

Optical encoders excel in clean, controlled environments due to their high resolution and precision but are vulnerable to dust, dirt, and moisture, which can impair performance. Magnetic encoders offer superior robustness and environmental suitability, operating effectively in harsh conditions with exposure to dirt, oil, and vibration, thanks to their contactless sensing technology. The choice between optical and magnetic encoders hinges on the application's environmental demands and required durability.

Cost Analysis: Optical vs Magnetic Encoders

Optical encoders generally have a higher initial cost due to their complex design and precision components, but they offer superior resolution and accuracy, which can reduce system errors and maintenance expenses over time. Magnetic encoders tend to be more cost-effective upfront, providing durability in harsh environments and lower maintenance requirements, making them suitable for budget-conscious applications where extreme precision is less critical. When considering total cost of ownership, optical encoders may incur additional costs from environmental sensitivity and wear, whereas magnetic encoders deliver consistent performance with lower life-cycle costs in vibration-prone or dirty environments.

Typical Applications for Each Encoder Type

Optical encoders are typically used in applications requiring high precision and resolution, such as CNC machines, robotics, and medical imaging devices, where accurate position feedback is critical. Magnetic encoders excel in harsh environments like automotive systems, industrial automation, and outdoor equipment due to their durability and resistance to dust, dirt, and moisture. Your choice between optical and magnetic encoders depends on the specific operational conditions and precision requirements of your application.

Maintenance and Longevity Considerations

Optical encoders require regular cleaning and careful handling to prevent dust and debris from affecting their precision, while magnetic encoders offer greater resilience to harsh environments due to their sealed designs and robust components. You can expect longer operational lifespans from magnetic encoders with fewer maintenance interventions, making them ideal for applications where durability is critical. Proper maintenance of optical encoders, however, can ensure accurate performance, but their delicate optical components are inherently more susceptible to wear and contamination.

Choosing the Right Encoder for Your Application

Optical encoders provide high resolution and accuracy, making them ideal for applications requiring precise position feedback in clean environments such as robotics and CNC machines. Magnetic encoders offer better durability and resistance to dust, dirt, and moisture, suited for harsh industrial conditions and outdoor use. Selecting the right encoder depends on balancing environmental factors, resolution needs, and cost-effectiveness for your specific application.

Optical Encoder vs Magnetic Encoder Infographic

electrown.com

electrown.com