Photoelectric sensors detect objects by emitting a light beam and measuring the reflected light, making them ideal for clear target detection and long-range sensing. Fiber optic sensors use flexible fiber cables to transmit light to hard-to-reach or delicate areas, providing precision in confined spaces; explore the rest of this article to understand which sensor suits Your application best.

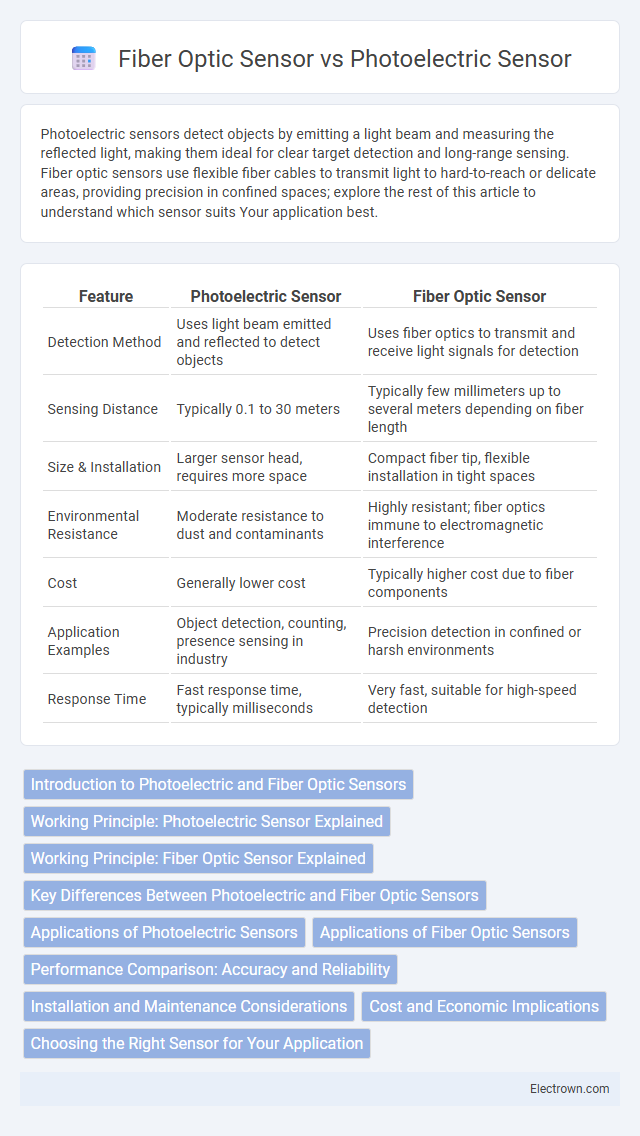

Table of Comparison

| Feature | Photoelectric Sensor | Fiber Optic Sensor |

|---|---|---|

| Detection Method | Uses light beam emitted and reflected to detect objects | Uses fiber optics to transmit and receive light signals for detection |

| Sensing Distance | Typically 0.1 to 30 meters | Typically few millimeters up to several meters depending on fiber length |

| Size & Installation | Larger sensor head, requires more space | Compact fiber tip, flexible installation in tight spaces |

| Environmental Resistance | Moderate resistance to dust and contaminants | Highly resistant; fiber optics immune to electromagnetic interference |

| Cost | Generally lower cost | Typically higher cost due to fiber components |

| Application Examples | Object detection, counting, presence sensing in industry | Precision detection in confined or harsh environments |

| Response Time | Fast response time, typically milliseconds | Very fast, suitable for high-speed detection |

Introduction to Photoelectric and Fiber Optic Sensors

Photoelectric sensors detect objects, changes in surface conditions, or distances by emitting and receiving light signals, making them ideal for non-contact detection in automation industries. Fiber optic sensors use flexible fiber optic cables to transmit light signals to and from sensing points, offering advantages in tight spaces or hazardous environments where traditional sensors cannot be placed. Your choice between these sensors depends on the application's spatial requirements, sensitivity needs, and environmental conditions.

Working Principle: Photoelectric Sensor Explained

Photoelectric sensors operate by emitting a beam of light, usually infrared, from an emitter to a receiver and detecting changes in the light intensity caused by the presence or absence of an object. When an object interrupts or reflects the light beam, the sensor triggers a response by converting the light signal into an electrical signal. These sensors are commonly used in industrial automation for object detection, counting, and positioning due to their non-contact detection capability and reliable performance.

Working Principle: Fiber Optic Sensor Explained

Fiber optic sensors operate by transmitting light through flexible fiber optic cables, detecting changes in light intensity caused by the presence, absence, or movement of an object. Unlike photoelectric sensors that emit and receive light directly through a transmitter and receiver, fiber optic sensors rely on the fiber cable to deliver light to confined or hazardous spaces, improving sensitivity and precision in challenging environments. Your choice between these sensors depends on application requirements such as detection distance, environmental conditions, and space constraints.

Key Differences Between Photoelectric and Fiber Optic Sensors

Photoelectric sensors use a light transmitter and receiver to detect objects by measuring the interruption or reflection of the light beam, while fiber optic sensors rely on flexible fiber optic cables to transmit light to and from the sensing point for detecting small or intricate objects. Photoelectric sensors are typically larger and better suited for direct line-of-sight detection in open environments, whereas fiber optic sensors excel in confined spaces, harsh conditions, and applications requiring precise or sensitive measurements. The choice between the two depends on factors such as detection distance, environmental conditions, sensor size, and application complexity.

Applications of Photoelectric Sensors

Photoelectric sensors are widely used in industrial automation to detect object presence, position, and distance in manufacturing assembly lines, packaging, and material handling systems. Their high-speed response and long sensing range make them ideal for applications like counting items on conveyors, detecting transparent objects, and ensuring safety by monitoring machine guards. Common industries utilizing photoelectric sensors include automotive, food and beverage, pharmaceuticals, and electronics production.

Applications of Fiber Optic Sensors

Fiber optic sensors excel in applications requiring detection in confined spaces, hazardous environments, or areas with high electromagnetic interference, such as in chemical processing plants, medical devices, and aerospace systems. Their immunity to electrical noise and capability to operate over long distances make them ideal for precise measurement and monitoring tasks where traditional photoelectric sensors may fail. You benefit from enhanced sensitivity and durability when deploying fiber optic sensors in complex industrial automation and environmental monitoring scenarios.

Performance Comparison: Accuracy and Reliability

Photoelectric sensors offer high accuracy in detecting objects with varied shapes and colors, providing reliable performance in industrial automation. Fiber optic sensors excel in detecting small or hard-to-reach targets with exceptional precision due to their flexible, miniature sensing heads. Your choice depends on application needs, where fiber optic sensors ensure superior reliability in confined spaces, while photoelectric sensors deliver robust accuracy in broader environments.

Installation and Maintenance Considerations

Photoelectric sensors offer straightforward installation with fixed detection ranges and integrated emitters and receivers, simplifying alignment and reducing setup time. Fiber optic sensors require careful placement of separate fiber optic cables and sensor units, increasing installation complexity but providing flexibility for tight or hazardous spaces. Your choice should consider maintenance ease; photoelectric sensors typically need less frequent adjustments, while fiber optic sensors demand regular inspection of fiber cables for damage and contamination to ensure optimal performance.

Cost and Economic Implications

Photoelectric sensors generally offer lower initial costs and simpler installation compared to fiber optic sensors, making them more economical for standard applications. Fiber optic sensors, while typically more expensive upfront due to specialized components and installation requirements, provide enhanced durability and performance in harsh or confined environments, potentially reducing long-term maintenance costs. Evaluating your specific operational needs and environmental conditions helps determine which sensor type delivers the best cost-efficiency and return on investment.

Choosing the Right Sensor for Your Application

Selecting the right sensor depends on factors such as detection distance, environmental conditions, and object size. Photoelectric sensors offer longer sensing ranges and are ideal for larger objects in open spaces, while fiber optic sensors excel in tight, confined areas with small or delicate targets due to their flexible fiber cables. Understanding your application's specific requirements ensures you choose a sensor that optimizes performance and reliability.

Photoelectric Sensor vs Fiber Optic Sensor Infographic

electrown.com

electrown.com