Screw terminals provide a secure, mechanical connection by tightening a screw onto the wire, ensuring reliable conductivity, while spring terminals use a spring mechanism for quick, tool-free wire insertion and removal, ideal for faster installation. Discover which terminal type best suits your electrical project by reading the rest of the article.

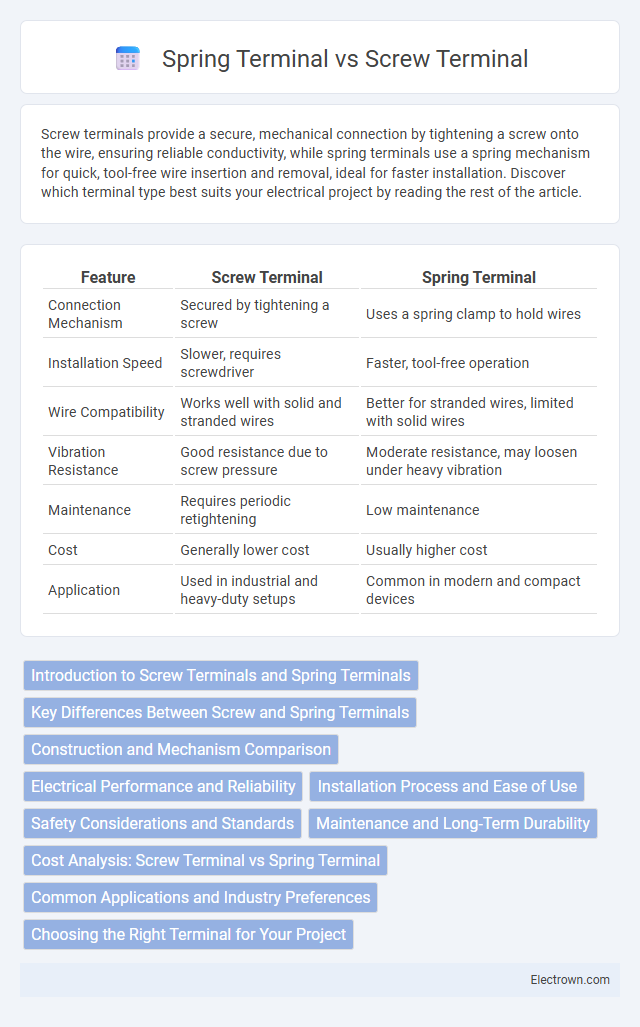

Table of Comparison

| Feature | Screw Terminal | Spring Terminal |

|---|---|---|

| Connection Mechanism | Secured by tightening a screw | Uses a spring clamp to hold wires |

| Installation Speed | Slower, requires screwdriver | Faster, tool-free operation |

| Wire Compatibility | Works well with solid and stranded wires | Better for stranded wires, limited with solid wires |

| Vibration Resistance | Good resistance due to screw pressure | Moderate resistance, may loosen under heavy vibration |

| Maintenance | Requires periodic retightening | Low maintenance |

| Cost | Generally lower cost | Usually higher cost |

| Application | Used in industrial and heavy-duty setups | Common in modern and compact devices |

Introduction to Screw Terminals and Spring Terminals

Screw terminals utilize a threaded fastener to secure wires by tightening the screw, providing a strong mechanical and electrical connection ideal for heavy-duty applications. Spring terminals use a spring mechanism to clamp wires quickly and securely, offering ease of installation and reliable vibration resistance suited for compact electronic devices. Both terminal types serve essential roles in electrical wiring, with screw terminals known for durability and spring terminals favored for speed and maintenance-free connections.

Key Differences Between Screw and Spring Terminals

Screw terminals secure wires by tightening a screw, ensuring a strong mechanical connection suitable for high-vibration environments, while spring terminals use a spring mechanism for quick, tool-free wire insertion, offering convenience and faster installation. Screw terminals support a wide range of wire sizes and provide excellent durability, whereas spring terminals excel in applications requiring frequent reconnections or maintenance with minimal risk of loosening. Your choice depends on whether you prioritize long-term stability with screw terminals or ease of use and flexibility with spring terminals.

Construction and Mechanism Comparison

Screw terminals feature a metal screw clamping mechanism that secures the wire by tightening the screw, providing a robust and reliable electrical connection ideal for high-vibration environments. Spring terminals utilize a spring-loaded clamp that holds the wire in place through tension, enabling quicker installation and removal without tools, which suits frequent maintenance scenarios. Your choice between these terminals affects connection stability and ease of use, depending on the application's mechanical and electrical demands.

Electrical Performance and Reliability

Screw terminals offer strong mechanical stability and excellent electrical conductivity due to the secure clamping force ensuring low contact resistance, making them reliable for high-current applications. Spring terminals provide consistent contact pressure that maintains stable connections under vibrations and thermal cycling, enhancing long-term reliability in environments subject to mechanical stress. Both terminal types deliver robust electrical performance, but screw terminals excel in high-load durability while spring terminals offer superior resilience against loosening and corrosion.

Installation Process and Ease of Use

Screw terminals require loosening screws to insert and secure wires, offering a reliable connection but demanding more time and manual effort during installation. Spring terminals use a spring-loaded mechanism that quickly clamps wires when inserted, enabling faster and tool-free installation with minimal risk of loose connections. The ease of use favors spring terminals for quick setups, while screw terminals provide greater control for precise wiring applications.

Safety Considerations and Standards

Screw terminals provide secure and reliable connections by tightly clamping wires, reducing the risk of loose contacts and electrical arcing, aligning with IEC 60998 and UL 1059 safety standards. Spring terminals offer protection against wire loosening due to vibration, enhancing safety in dynamic environments and complying with EN 60947-7-1 standards. Both terminal types prioritize insulation integrity and proper wire stripping lengths to prevent electrical faults and ensure compliance with NEC and international wiring regulations.

Maintenance and Long-Term Durability

Screw terminals require periodic maintenance to ensure tight connections and prevent corrosion, which can impact long-term durability if neglected. Spring terminals offer consistent tension without manual adjustment, reducing maintenance needs and maintaining reliable electrical contact over time. Your choice impacts system reliability and maintenance frequency based on the terminal type's inherent durability characteristics.

Cost Analysis: Screw Terminal vs Spring Terminal

Screw terminals typically involve higher installation costs due to the time required for manual tightening and maintenance, while spring terminals reduce labor expenses with faster, tool-free connections. Material costs for screw terminals may be lower, but spring terminals offer long-term savings by minimizing rework and improving reliability in vibration-prone environments. Your choice between screw terminal and spring terminal should consider both initial investment and total cost of ownership for efficient electrical connections.

Common Applications and Industry Preferences

Screw terminals are commonly used in industrial settings such as machinery control panels and heavy electrical equipment due to their secure, vibration-resistant connections, while spring terminals are favored in consumer electronics and automotive applications for their quick installation and maintenance-free design. Industries requiring frequent wiring changes or high reliability in dynamic environments often prefer spring terminals, whereas sectors prioritizing strong mechanical bonds under high current loads tend to choose screw terminals. Your decision between these terminals should account for application demands, ease of use, and industry-specific standards.

Choosing the Right Terminal for Your Project

Choosing the right terminal for your project depends on factors like installation speed, reliability, and maintenance requirements. Screw terminals offer strong mechanical connections ideal for high-vibration environments, while spring terminals provide faster wiring and better resistance to loosening over time. Evaluating your project's specific electrical load and environmental conditions ensures you select the most efficient and durable terminal type for your needs.

Screw Terminal vs Spring Terminal Infographic

electrown.com

electrown.com