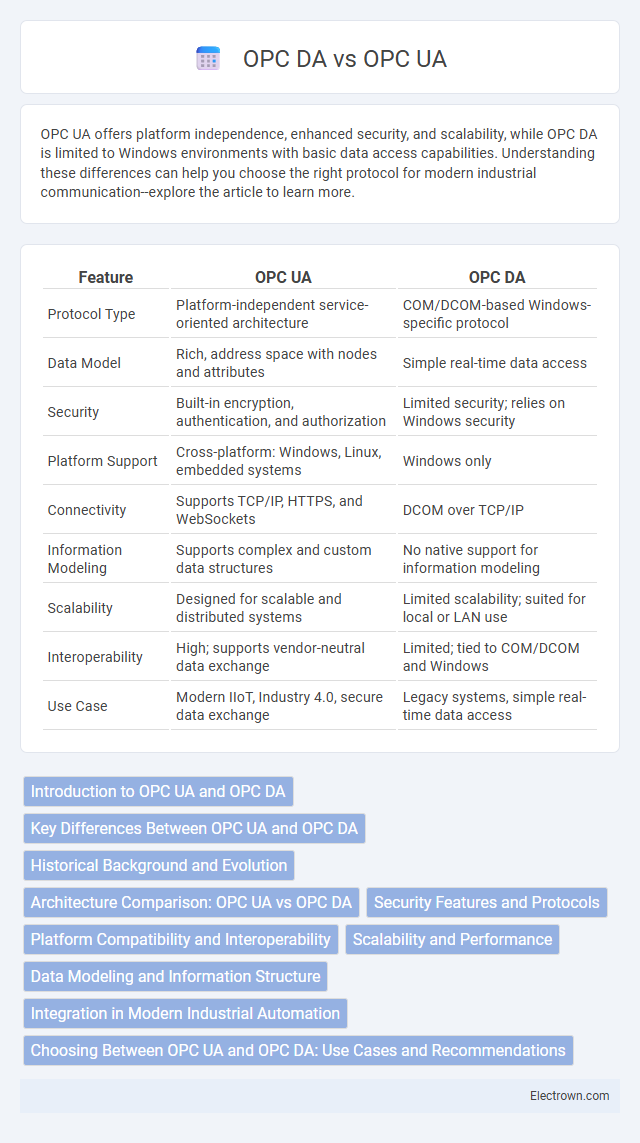

OPC UA offers platform independence, enhanced security, and scalability, while OPC DA is limited to Windows environments with basic data access capabilities. Understanding these differences can help you choose the right protocol for modern industrial communication--explore the article to learn more.

Table of Comparison

| Feature | OPC UA | OPC DA |

|---|---|---|

| Protocol Type | Platform-independent service-oriented architecture | COM/DCOM-based Windows-specific protocol |

| Data Model | Rich, address space with nodes and attributes | Simple real-time data access |

| Security | Built-in encryption, authentication, and authorization | Limited security; relies on Windows security |

| Platform Support | Cross-platform: Windows, Linux, embedded systems | Windows only |

| Connectivity | Supports TCP/IP, HTTPS, and WebSockets | DCOM over TCP/IP |

| Information Modeling | Supports complex and custom data structures | No native support for information modeling |

| Scalability | Designed for scalable and distributed systems | Limited scalability; suited for local or LAN use |

| Interoperability | High; supports vendor-neutral data exchange | Limited; tied to COM/DCOM and Windows |

| Use Case | Modern IIoT, Industry 4.0, secure data exchange | Legacy systems, simple real-time data access |

Introduction to OPC UA and OPC DA

OPC UA (Unified Architecture) is a modern, platform-independent communication protocol designed for secure and reliable industrial automation data exchange, supporting complex data modeling and cross-platform interoperability. OPC DA (Data Access) is an older OPC specification focused on real-time data communication within Windows-based environments, limited to simple data types and lacking platform independence. OPC UA enhances OPC DA by offering improved security, scalability, and extensibility for Industry 4.0 applications.

Key Differences Between OPC UA and OPC DA

OPC UA (Unified Architecture) offers platform independence, enhanced security with built-in encryption and authentication, and supports complex data types and information modeling, whereas OPC DA (Data Access) is limited to Windows platforms and primarily focuses on real-time data communication without native security features. OPC UA employs a service-oriented architecture supporting reliable communication across firewalls, while OPC DA relies on COM/DCOM technology, which often complicates network configurations and reduces scalability. The extensibility and interoperability of OPC UA make it suitable for Industry 4.0 and IIoT applications, in contrast to the legacy, device-centric approach of OPC DA.

Historical Background and Evolution

OPC UA (Unified Architecture) evolved from OPC DA (Data Access) to address limitations in interoperability, scalability, and security inherent in OPC DA's reliance on COM/DCOM technology since the 1990s. OPC UA introduced platform-independent communication, enhanced data modeling, and robust security features, reflecting industry demands for modern industrial automation protocols. Understanding this evolution helps you choose the appropriate protocol for integrating legacy systems with contemporary IIoT environments.

Architecture Comparison: OPC UA vs OPC DA

OPC UA features a service-oriented architecture that supports platform independence, secure communication, and complex data modeling, while OPC DA relies on a COM/DCOM-based architecture limited to Windows environments and primarily focused on real-time data access. OPC UA's architecture enables enhanced scalability, interoperability across diverse systems, and improved security mechanisms, whereas OPC DA's architecture is constrained by legacy protocols with limited extensibility. Your industrial automation system benefits from OPC UA's flexible architecture for future-proof integration compared to the more rigid, Windows-dependent OPC DA architecture.

Security Features and Protocols

OPC UA offers enhanced security features compared to OPC DA, including robust encryption, authentication, and user authorization, ensuring secure data exchange in industrial environments. OPC UA uses standardized protocols like TCP/IP and HTTPS with built-in security measures, while OPC DA relies on older DCOM technology, which is more vulnerable to cyber threats. Your industrial communication will benefit from OPC UA's advanced security frameworks, protecting sensitive data and maintaining system integrity.

Platform Compatibility and Interoperability

OPC UA offers platform compatibility across various operating systems including Windows, Linux, and embedded systems due to its independent and service-oriented architecture, unlike OPC DA which is limited to Windows environments dependent on COM/DCOM technology. OPC UA's interoperability extends beyond traditional industrial automation by supporting diverse data models and secure communication standards, facilitating integration with modern IT systems and cloud platforms. The enhanced cross-platform and cross-vendor interoperability of OPC UA enables seamless connectivity and data exchange in heterogeneous industrial ecosystems compared to the legacy OPC DA.

Scalability and Performance

OPC UA offers superior scalability and performance compared to OPC DA, supporting modern multi-platform environments and handling complex data types with enhanced security protocols. Its architecture allows seamless integration across distributed systems, enabling real-time data exchange and efficient resource utilization. By choosing OPC UA, your industrial communication can scale effortlessly while maintaining high throughput and low latency.

Data Modeling and Information Structure

OPC UA offers a robust and flexible data modeling framework that supports complex information structures through its address space model, enabling hierarchical and object-oriented representations of data. In contrast, OPC DA primarily handles flat, real-time data without native support for structured information or metadata, limiting its ability to represent complex data relationships. OPC UA's standardized information modeling enhances interoperability and allows seamless integration across diverse industrial systems and devices.

Integration in Modern Industrial Automation

OPC UA offers seamless integration in modern industrial automation with its platform-independent architecture and robust security features, enabling interoperability across diverse devices and systems. Unlike OPC DA, which relies on Windows-based COM/DCOM technology, OPC UA supports flexible communication over standard network protocols, facilitating scalable and cloud-connected industrial environments. The enhanced data modeling and standardized information exchange of OPC UA significantly improve real-time monitoring and predictive maintenance capabilities in Industry 4.0 frameworks.

Choosing Between OPC UA and OPC DA: Use Cases and Recommendations

OPC UA offers enhanced security, platform independence, and robust data modeling, making it suitable for modern industrial automation and IIoT applications, while OPC DA remains relevant for legacy systems requiring simple real-time data exchange on Windows platforms. Organizations integrating heterogeneous devices or needing cross-platform interoperability should prioritize OPC UA, whereas OPC DA is recommended for maintaining existing setups with limited scalability needs. Evaluating system complexity, future expansion, and security requirements is crucial when choosing between OPC UA and OPC DA.

OPC UA vs OPC DA Infographic

electrown.com

electrown.com