Open loop control operates without feedback, executing commands regardless of the output's actual state, which can lead to inaccuracies. Closed loop control continuously monitors output and adjusts inputs to achieve precise results, so explore the rest of this article to understand which system best suits your needs.

Table of Comparison

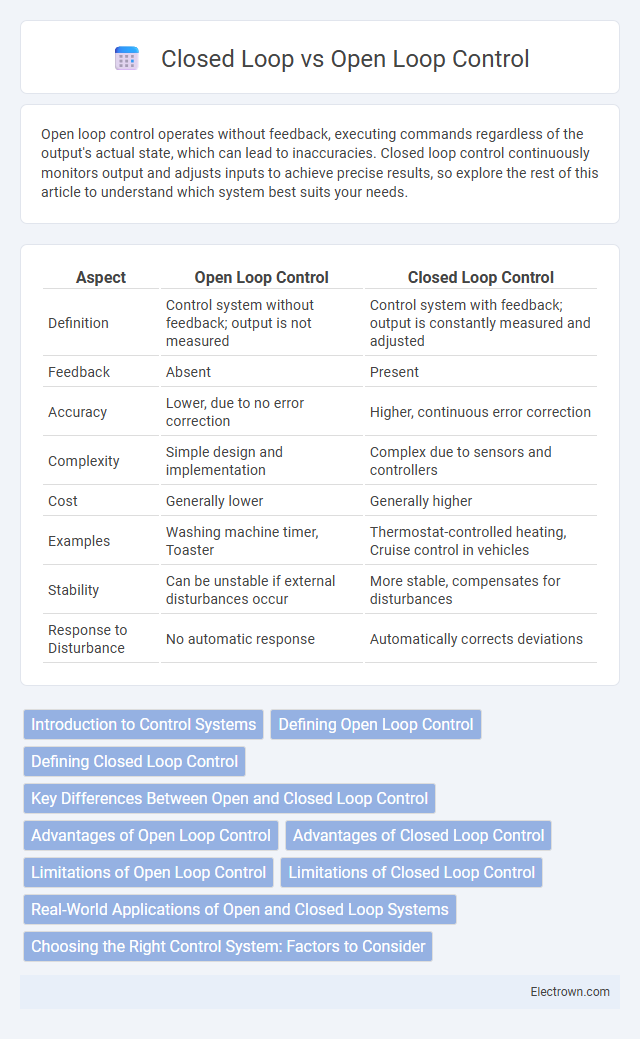

| Aspect | Open Loop Control | Closed Loop Control |

|---|---|---|

| Definition | Control system without feedback; output is not measured | Control system with feedback; output is constantly measured and adjusted |

| Feedback | Absent | Present |

| Accuracy | Lower, due to no error correction | Higher, continuous error correction |

| Complexity | Simple design and implementation | Complex due to sensors and controllers |

| Cost | Generally lower | Generally higher |

| Examples | Washing machine timer, Toaster | Thermostat-controlled heating, Cruise control in vehicles |

| Stability | Can be unstable if external disturbances occur | More stable, compensates for disturbances |

| Response to Disturbance | No automatic response | Automatically corrects deviations |

Introduction to Control Systems

Control systems regulate processes to achieve desired outputs, with Open Loop Control operating without feedback, relying solely on input commands. Closed Loop Control continuously monitors system output via sensors, adjusting inputs to correct deviations and maintain accuracy. Understanding these fundamental differences allows you to select the appropriate control strategy for efficient and precise system management.

Defining Open Loop Control

Open Loop Control refers to a control system where the output is not measured or fed back for adjustment, relying solely on predefined input commands. This system operates based on fixed instructions without considering external disturbances or system output variations. Open loop control is commonly used in simple applications where feedback is unnecessary or impractical, such as household appliances or basic motor controls.

Defining Closed Loop Control

Closed loop control is a system where the controller continuously monitors the output and adjusts inputs based on feedback to achieve the desired performance. This process relies on sensors to measure real-time data and compares it with the setpoint, enabling automatic correction of deviations. Closed loop control enhances accuracy, stability, and adaptability in industrial automation and robotics applications.

Key Differences Between Open and Closed Loop Control

Open loop control systems operate without feedback, relying solely on predefined inputs to manage processes, which can lead to inaccuracies if conditions change. Closed loop control systems use feedback from sensors to continuously adjust outputs, improving precision and adaptability in dynamic environments. The key difference lies in the presence of feedback, making closed loop systems more robust and capable of self-correction compared to open loop systems.

Advantages of Open Loop Control

Open loop control systems offer the advantage of simplicity, requiring fewer components and less complex circuitry, which reduces cost and maintenance efforts. They operate efficiently in environments with predictable and stable conditions, ensuring fast response times without the need for feedback. Open loop control also minimizes system instability since it does not rely on output monitoring, making it suitable for applications where precise accuracy is not critical.

Advantages of Closed Loop Control

Closed loop control offers precise regulation by continuously monitoring output and adjusting input to maintain desired performance, enhancing system accuracy and stability. Your processes benefit from improved disturbance rejection and adaptability to changing conditions, reducing errors and increasing reliability. This feedback mechanism ensures consistent quality and optimal operation in dynamic environments.

Limitations of Open Loop Control

Open loop control systems lack feedback mechanisms, which limits their ability to correct errors or adjust to disturbances in real time. These systems are highly sensitive to external changes and component variations, leading to reduced accuracy and reliability in dynamic environments. Without feedback, open loop controllers cannot compensate for system uncertainties, making them unsuitable for applications requiring precision and adaptability.

Limitations of Closed Loop Control

Closed loop control systems face limitations such as increased complexity and higher costs due to the need for continuous monitoring and feedback sensors. These systems can also exhibit instability or oscillations if the feedback loop is not properly tuned, which can degrade performance. Your application may suffer from slower response times and potential sensitivity to sensor noise, impacting overall system reliability.

Real-World Applications of Open and Closed Loop Systems

Open loop control systems are commonly used in simple applications like household appliances and irrigation systems where precise feedback is unnecessary, reducing cost and complexity. Closed loop control systems dominate critical applications such as industrial robotics, automotive cruise control, and HVAC systems due to their ability to continuously monitor and adjust performance, enhancing accuracy and stability. In aerospace and manufacturing automation, closed loop systems improve safety and efficiency by adapting to real-time environmental changes, while open loop systems are preferred in time-sensitive tasks with predictable outputs.

Choosing the Right Control System: Factors to Consider

Selecting the appropriate control system depends on the desired accuracy, system complexity, and environmental variability. Closed loop control offers superior precision and adaptability by continuously monitoring output, ideal for processes requiring real-time adjustments. Open loop control suits simpler, cost-sensitive applications with predictable conditions where feedback is unnecessary.

Open Loop vs Closed Loop Control Infographic

electrown.com

electrown.com