PLC systems offer fast, flexible control ideal for discrete manufacturing processes, while DCS provides integrated, scalable solutions best suited for continuous process industries. Explore the rest of the article to understand which system fits Your automation needs and operational goals.

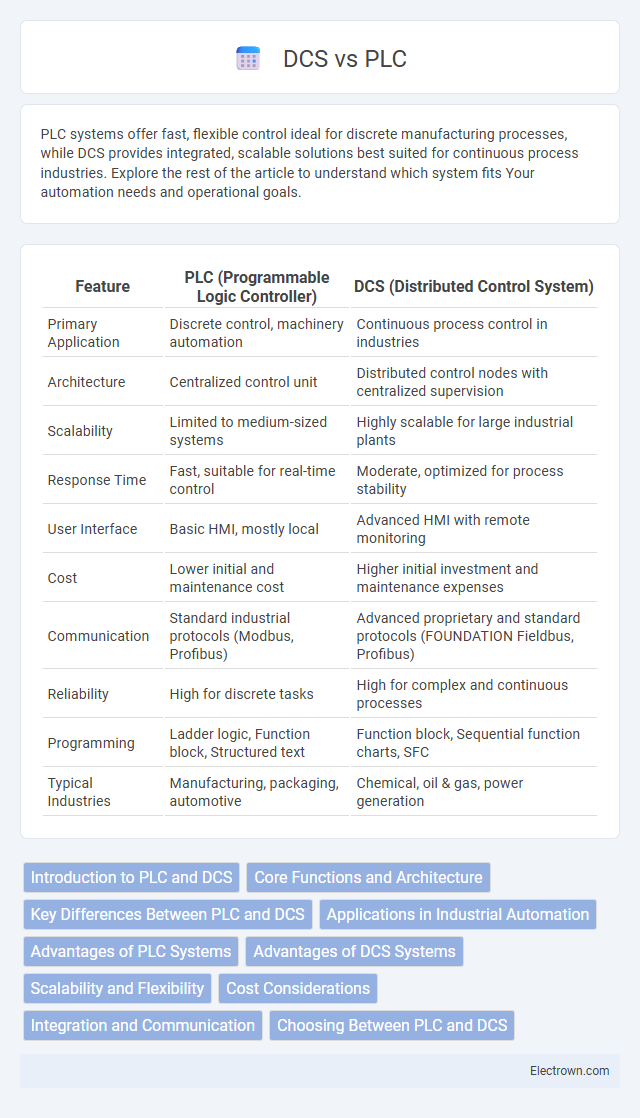

Table of Comparison

| Feature | PLC (Programmable Logic Controller) | DCS (Distributed Control System) |

|---|---|---|

| Primary Application | Discrete control, machinery automation | Continuous process control in industries |

| Architecture | Centralized control unit | Distributed control nodes with centralized supervision |

| Scalability | Limited to medium-sized systems | Highly scalable for large industrial plants |

| Response Time | Fast, suitable for real-time control | Moderate, optimized for process stability |

| User Interface | Basic HMI, mostly local | Advanced HMI with remote monitoring |

| Cost | Lower initial and maintenance cost | Higher initial investment and maintenance expenses |

| Communication | Standard industrial protocols (Modbus, Profibus) | Advanced proprietary and standard protocols (FOUNDATION Fieldbus, Profibus) |

| Reliability | High for discrete tasks | High for complex and continuous processes |

| Programming | Ladder logic, Function block, Structured text | Function block, Sequential function charts, SFC |

| Typical Industries | Manufacturing, packaging, automotive | Chemical, oil & gas, power generation |

Introduction to PLC and DCS

Programmable Logic Controllers (PLCs) are rugged digital computers designed for real-time industrial automation and control of machinery with fast response times. Distributed Control Systems (DCS) are sophisticated control architectures used for managing complex processes across multiple control loops with centralized monitoring and advanced data integration. Both PLC and DCS systems play critical roles in optimizing industrial operations but differ in scalability, application focus, and system complexity.

Core Functions and Architecture

PLC (Programmable Logic Controller) systems primarily execute discrete control tasks with a modular, real-time architecture designed for fast, reliable responses in automation processes. DCS (Distributed Control System) features a hierarchical, distributed architecture optimized for continuous process control, integrating multiple interconnected controllers and operator stations to manage complex industrial operations. The core function of PLCs revolves around input/output signal processing and logic control, while DCS emphasizes extensive data acquisition, process monitoring, and advanced regulatory control.

Key Differences Between PLC and DCS

PLCs (Programmable Logic Controllers) are designed for discrete control and fast response in smaller, specific applications, while DCS (Distributed Control Systems) manage complex, continuous processes across large industrial plants with integrated supervision. PLCs typically provide high-speed input/output processing and are modular, ideal for machine-level control, whereas DCS offers centralized control with distributed processors for process-level automation and extensive data handling. Your choice between PLC and DCS depends on factors like scalability, system complexity, process type, and the need for advanced process monitoring and control integration.

Applications in Industrial Automation

PLCs excel in discrete manufacturing processes such as automotive assembly lines, packaging, and material handling due to their rapid processing and flexibility. DCS systems are preferred for continuous, complex processes like chemical plants, oil refineries, and power generation, offering advanced control and monitoring capabilities. Your choice between PLC and DCS depends on the scale and complexity of the industrial automation application.

Advantages of PLC Systems

PLC systems offer high flexibility and scalability, making them ideal for discrete manufacturing and complex control processes requiring rapid modifications. Their modular design allows quick integration with various sensors and actuators, resulting in reduced setup times and maintenance costs. PLCs also provide real-time processing speeds and robust fault diagnostics, enhancing operational efficiency and minimizing downtime in industrial environments.

Advantages of DCS Systems

DCS systems offer superior scalability and integration capabilities, making them ideal for complex, large-scale industrial processes requiring centralized control. Enhanced reliability and fault tolerance minimize downtime, ensuring continuous operation in critical manufacturing environments. Your facility benefits from advanced data analytics and real-time monitoring, improving process optimization and operational efficiency.

Scalability and Flexibility

PLCs offer high flexibility with modular designs that easily adapt to smaller or medium-sized automation systems, making them ideal for applications requiring quick changes or expansions. DCS systems provide superior scalability for large, complex industrial processes, supporting extensive distributed control with integrated redundancy and advanced process management features. The choice between PLC and DCS depends on the scale of the operation and the need for integration complexity versus modular adaptability.

Cost Considerations

PLC systems typically offer lower initial investment and are more cost-effective for smaller or less complex automation projects, making them ideal for budget-conscious operations. DCS solutions involve higher upfront costs due to integrated control features and robustness, suitable for large-scale industrial processes requiring extensive monitoring and control. Your decision should weigh the total cost of ownership, including maintenance and scalability, to align with your operational budget and control requirements.

Integration and Communication

Programmable Logic Controllers (PLC) offer flexible integration with a wide range of industrial devices through standardized communication protocols such as Modbus, Ethernet/IP, and Profibus, enabling efficient real-time control in discrete automation systems. Distributed Control Systems (DCS) provide tightly integrated communication frameworks ideal for continuous process control, featuring proprietary or industry-specific protocols that ensure high reliability and seamless data exchange across complex plant operations. The choice between PLC and DCS for integration and communication depends on system scale, process complexity, and the need for centralized vs. decentralized control architectures.

Choosing Between PLC and DCS

Choosing between PLC (Programmable Logic Controller) and DCS (Distributed Control System) depends on the complexity and scale of your industrial process. PLCs are ideal for discrete control tasks requiring high-speed processing and flexibility, while DCS offers superior integration for continuous, large-scale process automation with centralized monitoring and advanced control algorithms. Evaluate factors like system size, control requirements, and scalability to determine the best fit for your operational needs.

PLC vs DCS Infographic

electrown.com

electrown.com