Resistive loads convert electrical energy directly into heat without causing phase shifts between voltage and current, resulting in efficient power usage. Inductive loads, however, create a magnetic field that causes current to lag voltage, leading to reduced power factor and potential energy loss; explore the details to understand how these differences impact your electrical system.

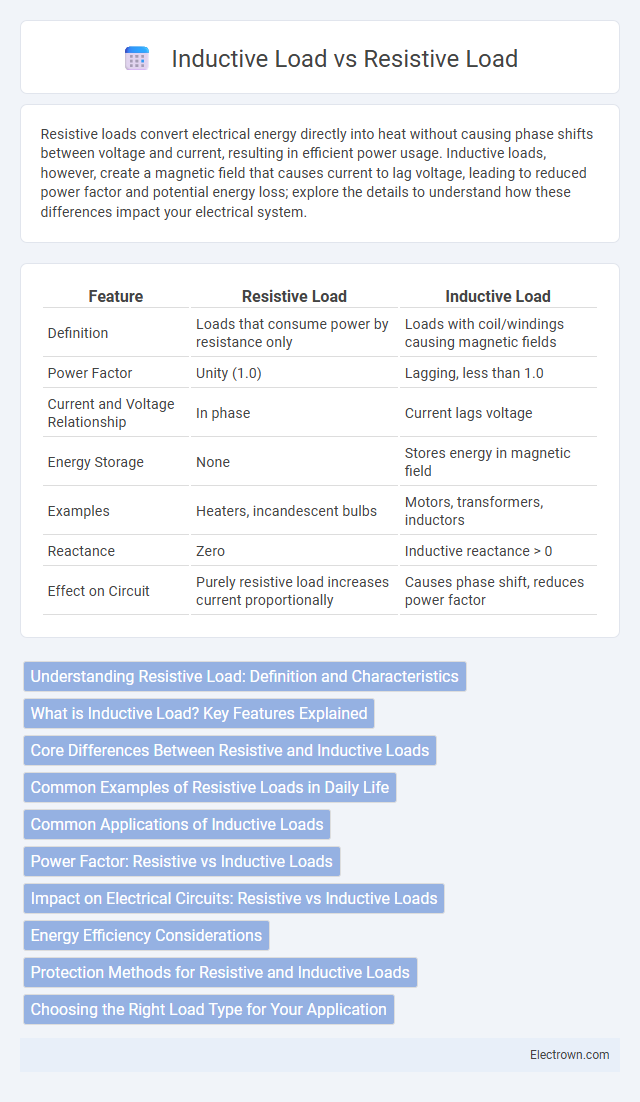

Table of Comparison

| Feature | Resistive Load | Inductive Load |

|---|---|---|

| Definition | Loads that consume power by resistance only | Loads with coil/windings causing magnetic fields |

| Power Factor | Unity (1.0) | Lagging, less than 1.0 |

| Current and Voltage Relationship | In phase | Current lags voltage |

| Energy Storage | None | Stores energy in magnetic field |

| Examples | Heaters, incandescent bulbs | Motors, transformers, inductors |

| Reactance | Zero | Inductive reactance > 0 |

| Effect on Circuit | Purely resistive load increases current proportionally | Causes phase shift, reduces power factor |

Understanding Resistive Load: Definition and Characteristics

Resistive load refers to electrical components or devices that primarily consume electrical energy by converting it into heat, characterized by a constant resistance that follows Ohm's law. These loads, such as incandescent bulbs and heating elements, exhibit a linear current-voltage relationship with power factor close to unity, indicating minimal reactive power. Understanding resistive load behavior is essential for accurate energy consumption analysis and efficient circuit design.

What is Inductive Load? Key Features Explained

An inductive load is an electrical device or component, such as motors, transformers, and solenoids, that primarily relies on magnetic fields to operate, causing current to lag voltage due to inductance. Key features include energy storage in magnetic fields, generation of reactive power, and phase difference between voltage and current, which can affect power factor and load efficiency. Understanding inductive loads is essential for proper circuit design, as they require compensation techniques like power factor correction to optimize electrical system performance.

Core Differences Between Resistive and Inductive Loads

Resistive loads convert electrical energy directly into heat or light with a constant resistance, resulting in current and voltage that are in phase. Inductive loads, such as motors and transformers, generate magnetic fields causing the current to lag behind the voltage, introducing reactive power and phase difference. The core difference lies in energy consumption: resistive loads dissipate energy, while inductive loads store and release energy through magnetic fields.

Common Examples of Resistive Loads in Daily Life

Common examples of resistive loads in daily life include incandescent light bulbs, electric heaters, toasters, and ovens, where electrical energy is directly converted into heat or light without phase shift between voltage and current. Resistive loads consume power proportionally to the voltage and current, providing straightforward energy conversion without reactive components. Understanding your appliances' resistive loading helps optimize energy use and reduce inefficiencies in household power consumption.

Common Applications of Inductive Loads

Inductive loads, such as motors, transformers, and solenoids, are widely used in industrial machinery, HVAC systems, and electric vehicle components due to their ability to store energy in magnetic fields. Unlike resistive loads, they cause phase shift between voltage and current, affecting power factor and requiring power factor correction in large-scale applications. Your understanding of inductive loads is crucial for designing efficient electrical systems that manage energy consumption and maintain system stability.

Power Factor: Resistive vs Inductive Loads

Resistive loads, such as heaters and incandescent bulbs, have a power factor close to 1, meaning they consume active power efficiently with minimal reactive power. Inductive loads, like motors and transformers, cause the power factor to drop below 1 due to the phase difference between voltage and current, leading to increased reactive power. Understanding your load's power factor is crucial for optimizing energy efficiency and reducing electricity costs.

Impact on Electrical Circuits: Resistive vs Inductive Loads

Resistive loads, such as heaters and incandescent bulbs, consume electrical power linearly, resulting in zero phase difference between voltage and current, which ensures maximum power transfer and minimal power losses. Inductive loads, including motors and transformers, cause a lagging power factor due to the phase shift between voltage and current, leading to reactive power that does not perform useful work but increases the total current in the circuit. This reactive current in inductive loads results in higher energy losses, voltage drops, and the need for power factor correction equipment in electrical systems.

Energy Efficiency Considerations

Resistive loads, such as incandescent bulbs and electric heaters, convert electrical energy directly into heat or light, resulting in near-100% energy efficiency with minimal reactive power. Inductive loads, including motors and transformers, cause phase differences between voltage and current, leading to increased reactive power and reduced power factor, which decreases overall energy efficiency. Improving energy efficiency in systems with inductive loads often requires power factor correction techniques like capacitor banks to minimize energy losses and optimize electrical consumption.

Protection Methods for Resistive and Inductive Loads

Protection methods for resistive loads involve using fuses and circuit breakers to prevent overheating and short circuits due to their purely resistive nature causing minimal inrush current. Inductive loads, such as motors and transformers, require protection devices like contactors with built-in snubber circuits or RC snubbers to suppress voltage spikes caused by inductive kickback. Installing surge protectors and using proper thermal overload relays ensures safe operation and extends the lifespan of both resistive and inductive load equipment.

Choosing the Right Load Type for Your Application

Resistive loads, such as heaters and incandescent bulbs, offer predictable power consumption with minimal phase difference between voltage and current, making them ideal for applications requiring consistent resistance and straightforward energy management. Inductive loads, including motors and transformers, introduce reactive power and cause phase shifts that must be accounted for in circuit design to prevent inefficiencies and voltage instability. Selecting the right load type depends on the specific application needs, with resistive loads suited for steady power levels and inductive loads preferred where energy storage and magnetic fields are essential.

Resistive Load vs Inductive Load Infographic

electrown.com

electrown.com