Power MOSFETs excel in high-speed switching and low voltage applications due to their fast response and efficiency, while IGBTs are better suited for high voltage and high current scenarios, offering robustness and lower conduction losses. Discover which device best fits your power electronics project by exploring the detailed comparison in this article.

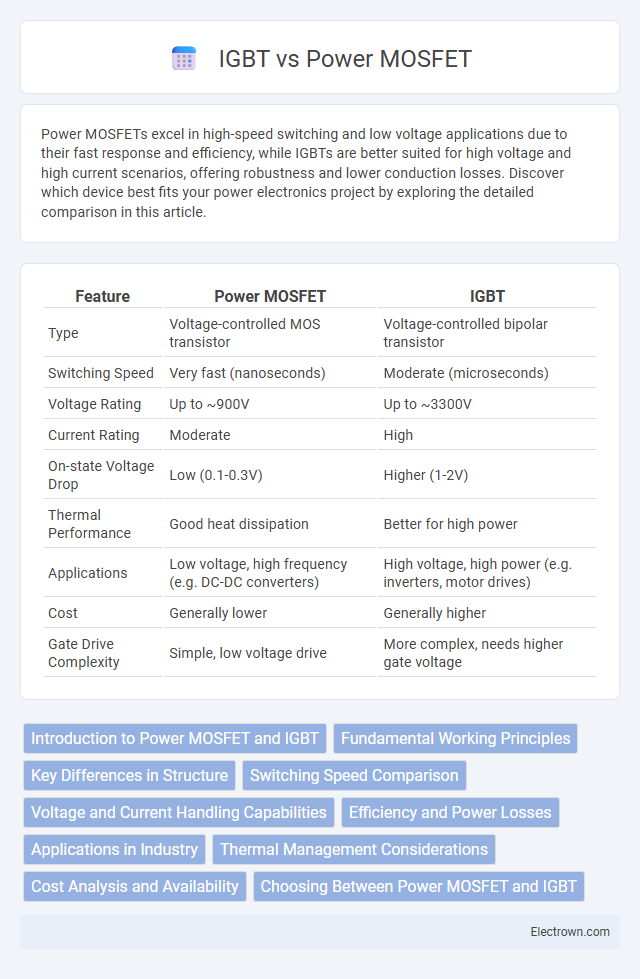

Table of Comparison

| Feature | Power MOSFET | IGBT |

|---|---|---|

| Type | Voltage-controlled MOS transistor | Voltage-controlled bipolar transistor |

| Switching Speed | Very fast (nanoseconds) | Moderate (microseconds) |

| Voltage Rating | Up to ~900V | Up to ~3300V |

| Current Rating | Moderate | High |

| On-state Voltage Drop | Low (0.1-0.3V) | Higher (1-2V) |

| Thermal Performance | Good heat dissipation | Better for high power |

| Applications | Low voltage, high frequency (e.g. DC-DC converters) | High voltage, high power (e.g. inverters, motor drives) |

| Cost | Generally lower | Generally higher |

| Gate Drive Complexity | Simple, low voltage drive | More complex, needs higher gate voltage |

Introduction to Power MOSFET and IGBT

Power MOSFETs, or Metal-Oxide-Semiconductor Field-Effect Transistors, are semiconductor devices designed for high-speed switching with low on-resistance, making them ideal for efficient power conversion in low-voltage applications. Insulated Gate Bipolar Transistors (IGBTs) combine the high input impedance of MOSFETs with the low conduction losses of bipolar transistors, excelling in high-voltage and high-current power electronics like motor drives and inverters. Understanding your application's voltage, current, and switching frequency requirements will help determine whether a Power MOSFET or an IGBT is the optimal choice for reliable and efficient performance.

Fundamental Working Principles

Power MOSFETs operate using voltage-controlled channels in a semiconductor, where an electric field modulates conductivity between the source and drain terminals, enabling fast switching and low on-resistance performance. IGBTs combine the gate structure of MOSFETs with the bipolar junction transistor's conductivity modulation, allowing high current and voltage handling capabilities through minority carrier injection in their p-n-p-n structure. The fundamental difference lies in the MOSFET's unipolar conduction mechanism versus the IGBT's bipolar conduction, impacting switching speed, efficiency, and thermal characteristics.

Key Differences in Structure

Power MOSFETs feature an insulated gate structure with a vertical channel, enabling fast switching and low gate drive power, whereas IGBTs combine MOS gate control with a bipolar conduction path, resulting in higher current capacity but slower switching. The MOSFET's n-channel or p-channel configuration offers unipolar conduction, while the IGBT's multi-layered structure includes a pnp transistor and an n-channel MOSFET in one device, influencing their voltage and current handling capabilities. Your choice between these devices depends on the specific structural benefits suited to switching speed, voltage rating, and efficiency requirements.

Switching Speed Comparison

Power MOSFETs exhibit significantly faster switching speeds compared to IGBTs due to their majority carrier operation and lower charge storage effects, enabling efficient performance in high-frequency applications. IGBTs, being bipolar devices with minority carrier injection, experience slower turn-off times and increased switching losses, limiting their use in rapid switching scenarios. Your choice between these devices should consider the switching speed requirements of your application to optimize efficiency and thermal management.

Voltage and Current Handling Capabilities

Power MOSFETs excel in high-frequency applications due to their rapid switching and superior efficiency at voltages typically below 250V, making them ideal for low to medium power levels. IGBTs, on the other hand, handle higher voltages, often exceeding 600V, and support larger current loads, which suits them for medium to high power applications such as motor drives and industrial inverters. Understanding the voltage and current requirements of Your system is crucial when choosing between Power MOSFETs and IGBTs for optimal performance and durability.

Efficiency and Power Losses

Power MOSFETs demonstrate higher efficiency at low voltages due to their low on-resistance (R_DS(on)), resulting in reduced conduction losses and improved switching speed. IGBTs offer superior performance in high-voltage, high-current applications by minimizing switching losses despite higher conduction losses compared to MOSFETs. Selecting between Power MOSFETs and IGBTs depends on voltage levels and switching frequency, directly impacting overall power losses and system efficiency.

Applications in Industry

Power MOSFETs excel in high-frequency switching applications such as DC-DC converters and motor drives due to their fast switching speeds and low gate charge. IGBTs are preferred in high-power applications like industrial motor control, induction heating, and traction systems because of their capability to handle higher voltages and currents efficiently. Your choice between Power MOSFET and IGBT will depend on the specific industry's voltage, current, and switching frequency requirements.

Thermal Management Considerations

Power MOSFETs exhibit lower thermal resistance and can operate efficiently at higher switching frequencies, but require careful thermal management to avoid overheating due to their typically lower current capacity. IGBTs handle higher currents and voltages with better robustness for thermal stress, yet they generate more heat during conduction and need substantial cooling solutions such as heat sinks or liquid cooling. Effective thermal management for both devices involves optimizing heat dissipation through PCB layout, thermal interface materials, and active cooling systems to enhance reliability and performance in power electronics applications.

Cost Analysis and Availability

Power MOSFETs generally offer lower initial costs and higher availability due to widespread use in low to medium voltage applications, making them more budget-friendly for users. IGBTs, suited for high voltage and high current scenarios, typically incur higher costs linked to more complex manufacturing processes and limited suppliers. Your choice should weigh the balance between upfront cost and specific application requirements to optimize both expense and component accessibility.

Choosing Between Power MOSFET and IGBT

Power MOSFETs are ideal for high-frequency switching and low-voltage applications up to 250V due to their fast switching speeds and low conduction losses. IGBTs excel in high-voltage, high-current environments above 600V, offering robust performance for medium- to low-frequency operations despite slower switching speeds. Selecting between Power MOSFET and IGBT depends on voltage requirements, switching frequency, conduction efficiency, and thermal management needs.

Power MOSFET vs IGBT Infographic

electrown.com

electrown.com