LVDT (Linear Variable Differential Transformer) and RVDT (Rotary Variable Differential Transformer) are precise sensors used for measuring linear and angular displacement respectively, offering high accuracy and reliability in various industrial applications. Discover how choosing between LVDT and RVDT can impact your measurement needs and enhance system performance by reading the full article.

Table of Comparison

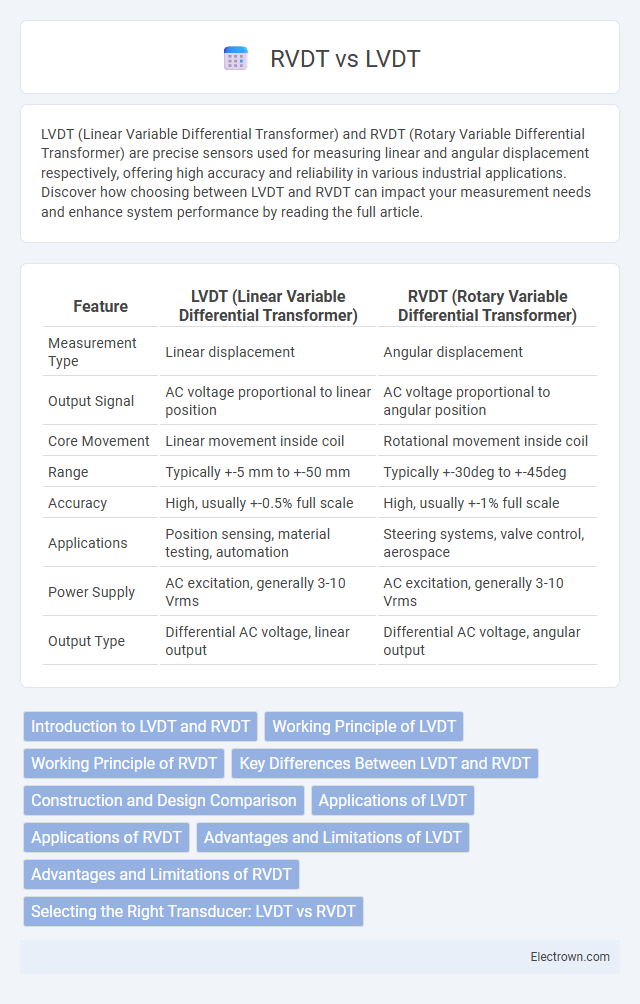

| Feature | LVDT (Linear Variable Differential Transformer) | RVDT (Rotary Variable Differential Transformer) |

|---|---|---|

| Measurement Type | Linear displacement | Angular displacement |

| Output Signal | AC voltage proportional to linear position | AC voltage proportional to angular position |

| Core Movement | Linear movement inside coil | Rotational movement inside coil |

| Range | Typically +-5 mm to +-50 mm | Typically +-30deg to +-45deg |

| Accuracy | High, usually +-0.5% full scale | High, usually +-1% full scale |

| Applications | Position sensing, material testing, automation | Steering systems, valve control, aerospace |

| Power Supply | AC excitation, generally 3-10 Vrms | AC excitation, generally 3-10 Vrms |

| Output Type | Differential AC voltage, linear output | Differential AC voltage, angular output |

Introduction to LVDT and RVDT

LVDT (Linear Variable Differential Transformer) and RVDT (Rotary Variable Differential Transformer) are electromechanical sensors used for precise displacement measurement. LVDT measures linear displacement through the movement of a ferromagnetic core inside a coil assembly, while RVDT measures angular displacement via the rotation of a magnetic core. Both devices provide high accuracy, frictionless operation, and wide dynamic range, making them essential in industrial automation and aerospace applications.

Working Principle of LVDT

The working principle of an LVDT (Linear Variable Differential Transformer) is based on electromagnetic induction, where a primary coil is energized with an alternating current inducing voltages in two secondary coils. The movable ferromagnetic core inside the coil assembly changes the magnetic flux linkage between the primary and secondary coils, causing a differential voltage output proportional to the core's linear position. Your choice of an LVDT enables highly accurate, frictionless, and contactless displacement measurement suitable for precise linear position sensing applications.

Working Principle of RVDT

The Rotary Variable Differential Transformer (RVDT) operates on the same electromagnetic induction principles as the Linear Variable Differential Transformer (LVDT), but it measures angular displacement instead of linear movement. The RVDT consists of a primary winding, energized by an AC source, and two symmetrically placed secondary windings on a rotor, which moves with angular displacement to induce voltages proportional to the angle. The differential voltage output of the secondary windings varies linearly with the rotor position, allowing precise measurement of angular position.

Key Differences Between LVDT and RVDT

LVDT (Linear Variable Differential Transformer) measures linear displacement while RVDT (Rotary Variable Differential Transformer) detects angular displacement. LVDTs provide high precision and frictionless measurement of linear position with a linear output signal, whereas RVDTs offer accurate rotational position sensing through non-contact magnetic coupling. Both sensors utilize differential transformer principles but differ primarily in their mechanical movement types and output signal characterization.

Construction and Design Comparison

LVDT (Linear Variable Differential Transformer) features a cylindrical core that moves linearly within a coil assembly, providing precise linear displacement measurement. RVDT (Rotary Variable Differential Transformer) incorporates a rotor that rotates inside a stator winded with coils, enabling accurate angular displacement detection. The LVDT's core slides along the axis for translational sensing, while the RVDT's armature pivots to convert rotational movement into an electrical signal.

Applications of LVDT

LVDTs (Linear Variable Differential Transformers) are widely used in precision measurement applications such as aerospace for monitoring actuator positions, industrial automation for controlling hydraulic cylinders, and robotics for accurate linear displacement sensing. Their non-contact operation and high sensitivity enable reliable performance in harsh environments like nuclear reactors and automotive testing. LVDTs excel in applications requiring high repeatability and resolution, including material testing machines and servo valve position feedback systems.

Applications of RVDT

RVDTs (Rotary Variable Differential Transformers) are widely used in applications requiring precise angular position sensing, such as in aerospace for control surface position feedback and in industrial automation for rotary encoder replacement. Their ability to provide continuous, high-resolution rotary displacement measurements makes them ideal for robotics and servo motor control systems. You can rely on RVDTs for accurate and robust performance in harsh environments where precise rotational feedback is critical.

Advantages and Limitations of LVDT

LVDTs (Linear Variable Differential Transformers) offer high accuracy, frictionless operation, and excellent repeatability, making them ideal for precise linear displacement measurements. They provide an infinite resolution and robust structure that can withstand harsh environments, but their reliance on an AC excitation source limits their use in certain applications. However, LVDTs are sensitive to electromagnetic interference and require complex signal conditioning, which may increase overall system cost and complexity.

Advantages and Limitations of RVDT

RVDTs (Rotary Variable Differential Transformers) offer precise angular displacement measurement with high resolution and linearity, making them ideal for applications requiring rotational position sensing. Their contactless operation reduces wear and extends lifespan, while their robustness allows functioning in harsh environments, including high temperatures and electromagnetic interference zones. Limitations include sensitivity to misalignment and a typically lower angular range compared to rotary encoders, posing challenges in applications demanding full 360-degree rotation or very high-speed rotation detection.

Selecting the Right Transducer: LVDT vs RVDT

Selecting the right transducer involves evaluating application requirements such as linear versus angular displacement measurement, accuracy, and environmental conditions. LVDTs (Linear Variable Differential Transformers) excel in precise linear position sensing with high resolution and frictionless operation, making them ideal for dimensional measurement and material testing. RVDTs (Rotary Variable Differential Transformers) are optimized for angular displacement, offering robust performance in rotary applications like valve position feedback and control systems.

LVDT vs RVDT Infographic

electrown.com

electrown.com