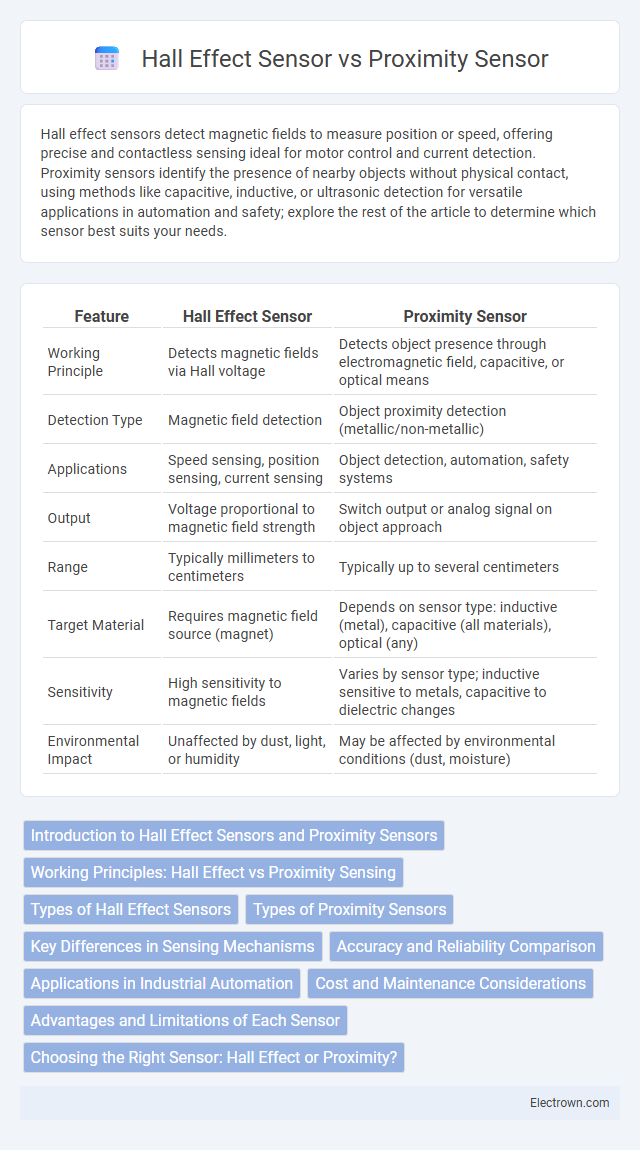

Hall effect sensors detect magnetic fields to measure position or speed, offering precise and contactless sensing ideal for motor control and current detection. Proximity sensors identify the presence of nearby objects without physical contact, using methods like capacitive, inductive, or ultrasonic detection for versatile applications in automation and safety; explore the rest of the article to determine which sensor best suits your needs.

Table of Comparison

| Feature | Hall Effect Sensor | Proximity Sensor |

|---|---|---|

| Working Principle | Detects magnetic fields via Hall voltage | Detects object presence through electromagnetic field, capacitive, or optical means |

| Detection Type | Magnetic field detection | Object proximity detection (metallic/non-metallic) |

| Applications | Speed sensing, position sensing, current sensing | Object detection, automation, safety systems |

| Output | Voltage proportional to magnetic field strength | Switch output or analog signal on object approach |

| Range | Typically millimeters to centimeters | Typically up to several centimeters |

| Target Material | Requires magnetic field source (magnet) | Depends on sensor type: inductive (metal), capacitive (all materials), optical (any) |

| Sensitivity | High sensitivity to magnetic fields | Varies by sensor type; inductive sensitive to metals, capacitive to dielectric changes |

| Environmental Impact | Unaffected by dust, light, or humidity | May be affected by environmental conditions (dust, moisture) |

Introduction to Hall Effect Sensors and Proximity Sensors

Hall Effect sensors detect magnetic fields by measuring voltage changes caused by magnetic flux, making them ideal for precise position and speed sensing in automotive and industrial applications. Proximity sensors, including inductive, capacitive, and ultrasonic types, detect the presence or absence of objects without physical contact, commonly used for object detection and automation control. Both sensor types offer non-contact sensing solutions, but Hall Effect sensors specialize in magnetic field detection while proximity sensors provide broader material and distance detection capabilities.

Working Principles: Hall Effect vs Proximity Sensing

Hall Effect sensors operate by detecting changes in magnetic field strength using a semiconductor element that generates a voltage proportional to the magnetic flux density, enabling precise measurement of magnetic fields and position. Proximity sensors function by detecting the presence or absence of objects through methods such as inductive, capacitive, ultrasonic, or infrared sensing, which rely on changes in electromagnetic fields, capacitance, sound waves, or light reflections. The Hall Effect sensor is best suited for applications involving magnetic target detection, while proximity sensors are versatile for non-contact object detection across various material types.

Types of Hall Effect Sensors

Hall Effect sensors are categorized into three main types: analog, digital, and linear sensors, each designed to detect magnetic fields with varying sensitivity and output signals. Analog Hall Effect sensors provide a continuous voltage output proportional to the magnetic field strength, ideal for precise measurements. Digital Hall Effect sensors offer a binary output indicating presence or absence of a magnetic field, commonly used in position and speed detection applications, while linear Hall Effect sensors deliver a variable output for advanced position sensing and current measurement tasks.

Types of Proximity Sensors

Proximity sensors include capacitive, inductive, ultrasonic, and optical types, each designed to detect objects without physical contact. Inductive proximity sensors detect metallic objects using electromagnetic fields, similar to Hall effect sensors that sense magnetic fields but with higher sensitivity to magnetism. Capacitive sensors identify both metallic and non-metallic materials by measuring changes in capacitance, offering versatility beyond the Hall effect sensor's scope.

Key Differences in Sensing Mechanisms

Hall effect sensors detect magnetic fields by measuring voltage changes generated when a magnetic field interacts with a semiconductor material, enabling precise detection of magnetic presence and strength. Proximity sensors operate using various methods such as capacitive, inductive, ultrasonic, or optical principles to detect the presence or absence of nearby objects without direct contact. The fundamental difference lies in Hall effect sensors relying specifically on magnetic field detection, whereas proximity sensors employ diverse physical phenomena to sense object proximity.

Accuracy and Reliability Comparison

Hall Effect sensors offer superior accuracy in detecting magnetic fields with precise measurements of magnetic flux density, making them highly reliable for applications requiring consistent position or speed sensing. Proximity sensors, which detect objects without contact through capacitive, inductive, or ultrasonic means, can be affected by environmental factors such as dirt, moisture, or surface materials, potentially reducing their reliability and accuracy. When choosing between the two, your decision should consider the need for precise magnetic detection versus general object presence, as Hall Effect sensors generally provide more stable and repeatable results in controlled magnetic environments.

Applications in Industrial Automation

Hall Effect sensors provide precise and contactless detection of magnetic fields, making them ideal for monitoring the position and speed of rotating machinery in industrial automation. Proximity sensors, including inductive and capacitive types, are widely used for object detection, part counting, and presence sensing on assembly lines. Both sensor types enhance automation efficiency by enabling accurate, real-time feedback in manufacturing processes, with Hall Effect sensors favored for motion control and proximity sensors preferred for object detection.

Cost and Maintenance Considerations

Hall effect sensors generally offer a lower initial cost and reduced maintenance due to their solid-state design, which eliminates mechanical parts prone to wear. Proximity sensors, especially inductive and capacitive types, may have higher upfront costs and require periodic calibration to maintain accuracy. Long-term expenses favor Hall effect sensors in industrial applications where durability and minimal upkeep are crucial.

Advantages and Limitations of Each Sensor

Hall Effect sensors offer high sensitivity to magnetic fields, enabling precise detection of position and speed with excellent durability in harsh environments. Proximity sensors provide versatile object detection without physical contact, suitable for a wide range of materials including metals, plastics, and liquids, with fast response times. However, Hall Effect sensors are limited to magnetic targets and require magnets, while proximity sensors may have reduced accuracy with non-metallic or electrically non-conductive objects and can be affected by environmental factors like dirt or moisture.

Choosing the Right Sensor: Hall Effect or Proximity?

Hall Effect sensors provide precise magnetic field detection ideal for applications requiring accurate position or speed measurement, while proximity sensors detect the presence or absence of nearby objects without physical contact, making them suitable for general object detection tasks. Choosing the right sensor depends on factors such as detection range, environmental conditions, and required sensitivity; Hall Effect sensors excel in detecting magnetic fields through metal objects, whereas proximity sensors cover broader materials including metal, plastic, and liquid. For environments with strong magnetic interference or where non-contact detection of various materials is essential, proximity sensors are often preferred, whereas Hall Effect sensors are optimal for high-precision magnetic applications.

Hall Effect Sensor vs Proximity Sensor Infographic

electrown.com

electrown.com