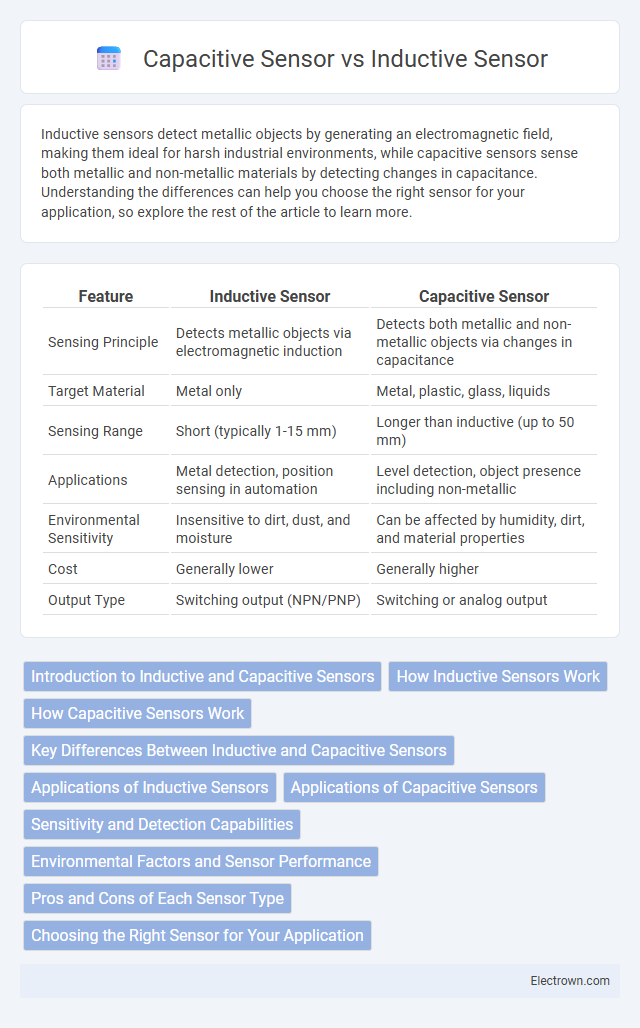

Inductive sensors detect metallic objects by generating an electromagnetic field, making them ideal for harsh industrial environments, while capacitive sensors sense both metallic and non-metallic materials by detecting changes in capacitance. Understanding the differences can help you choose the right sensor for your application, so explore the rest of the article to learn more.

Table of Comparison

| Feature | Inductive Sensor | Capacitive Sensor |

|---|---|---|

| Sensing Principle | Detects metallic objects via electromagnetic induction | Detects both metallic and non-metallic objects via changes in capacitance |

| Target Material | Metal only | Metal, plastic, glass, liquids |

| Sensing Range | Short (typically 1-15 mm) | Longer than inductive (up to 50 mm) |

| Applications | Metal detection, position sensing in automation | Level detection, object presence including non-metallic |

| Environmental Sensitivity | Insensitive to dirt, dust, and moisture | Can be affected by humidity, dirt, and material properties |

| Cost | Generally lower | Generally higher |

| Output Type | Switching output (NPN/PNP) | Switching or analog output |

Introduction to Inductive and Capacitive Sensors

Inductive sensors detect metal objects by generating an electromagnetic field and measuring changes caused by conductive materials, making them ideal for industrial automation and metal detection. Capacitive sensors detect both metallic and non-metallic objects by sensing changes in the dielectric constant, allowing them to measure liquids, plastics, and granular materials. These sensors provide versatile solutions across manufacturing, packaging, and process control industries due to their distinct sensing principles.

How Inductive Sensors Work

Inductive sensors operate by generating an electromagnetic field from a coil and detecting changes caused by metallic objects entering this field, which induces eddy currents and alters the coil's inductance. These sensors excel in detecting ferrous and non-ferrous metals without physical contact, making them ideal for industrial automation and metal detection applications. Their precise sensing capability relies on the principle of electromagnetic induction, ensuring reliable and fast responses in harsh environments.

How Capacitive Sensors Work

Capacitive sensors detect changes in capacitance between their sensor plate and an object, measuring the variation in the electric field caused by the presence or absence of that object. They operate by generating an electrostatic field, and when a target with a different dielectric constant approaches, it alters this field, triggering a response. Capacitive sensors can detect both conductive and non-conductive materials, making them versatile for applications involving liquids, plastics, and granular materials.

Key Differences Between Inductive and Capacitive Sensors

Inductive sensors detect metallic objects by generating an electromagnetic field, making them ideal for metal detection in industrial applications. Capacitive sensors sense changes in capacitance caused by both metallic and non-metallic materials, allowing detection of liquids, plastics, and powders. Understanding these key differences enables you to select the appropriate sensor type based on the target material and environmental conditions.

Applications of Inductive Sensors

Inductive sensors are widely used in industrial automation for detecting metal objects, making them ideal for metal detection in manufacturing processes, assembly lines, and robotics. Their robustness and resistance to dirt, oil, and water allow reliable use in harsh environments such as automotive production and packaging industries. You can rely on inductive sensors for precise position sensing, speed measurement, and proximity detection where metal targets are involved.

Applications of Capacitive Sensors

Capacitive sensors detect changes in capacitance caused by the presence of various materials, making them ideal for applications such as liquid level detection, proximity sensing, and object counting. They are widely used in industries for monitoring non-metallic objects like plastics, wood, or glass, which inductive sensors cannot reliably detect. Your control systems benefit from capacitive sensors' ability to sense through non-conductive materials, enhancing automation and quality control processes.

Sensitivity and Detection Capabilities

Inductive sensors excel in detecting metal objects with high sensitivity, making them ideal for industrial applications where precise metal sensing is crucial. Capacitive sensors offer broader detection capabilities by sensing both metallic and non-metallic materials, including liquids, plastics, and glass, due to their ability to detect changes in dielectric constant. Your choice depends on the application requirements, as inductive sensors provide superior metal detection sensitivity, while capacitive sensors enable versatile detection across various material types.

Environmental Factors and Sensor Performance

Inductive sensors excel in harsh industrial environments, demonstrating high resistance to dust, water, and metal contaminants due to their reliance on electromagnetic fields to detect metallic objects. Capacitive sensors, sensitive to changes in dielectric constant, perform well in detecting non-metallic materials but can be affected by environmental factors such as humidity, dust, and temperature fluctuations. Optimal sensor performance depends on choosing inductive sensors for robust metal detection in challenging conditions, while capacitive sensors suit applications requiring sensitivity to diverse material types yet controlled environments.

Pros and Cons of Each Sensor Type

Inductive sensors excel in detecting metallic objects with high precision and durability, offering immunity to dust, oil, and water, but their limitation lies in sensing non-metallic materials. Capacitive sensors can detect both metallic and non-metallic objects, including liquids, providing versatile applications; however, they are more sensitive to environmental factors such as humidity and temperature fluctuations, which can cause false triggers. Inductive sensors typically have a longer lifespan and stronger resistance to interference, while capacitive sensors require careful calibration to avoid sensitivity issues in complex environments.

Choosing the Right Sensor for Your Application

Inductive sensors excel in detecting metal objects with high precision and durability, making them ideal for industrial automation involving metal parts. Capacitive sensors offer versatility by sensing various materials, including liquids, plastics, and wood, suitable for applications requiring non-metal object detection or level sensing. Selecting the right sensor depends on the target material, environmental conditions, and required sensitivity for optimal performance.

Inductive Sensor vs Capacitive Sensor Infographic

electrown.com

electrown.com