Panel PCs integrate a touchscreen display and computing hardware into a single compact unit, ideal for user-friendly industrial applications requiring space-saving design and easy interaction. Explore the rest of the article to understand how your choice between a Panel PC and Industrial PC can impact performance, durability, and functionality in various environments.

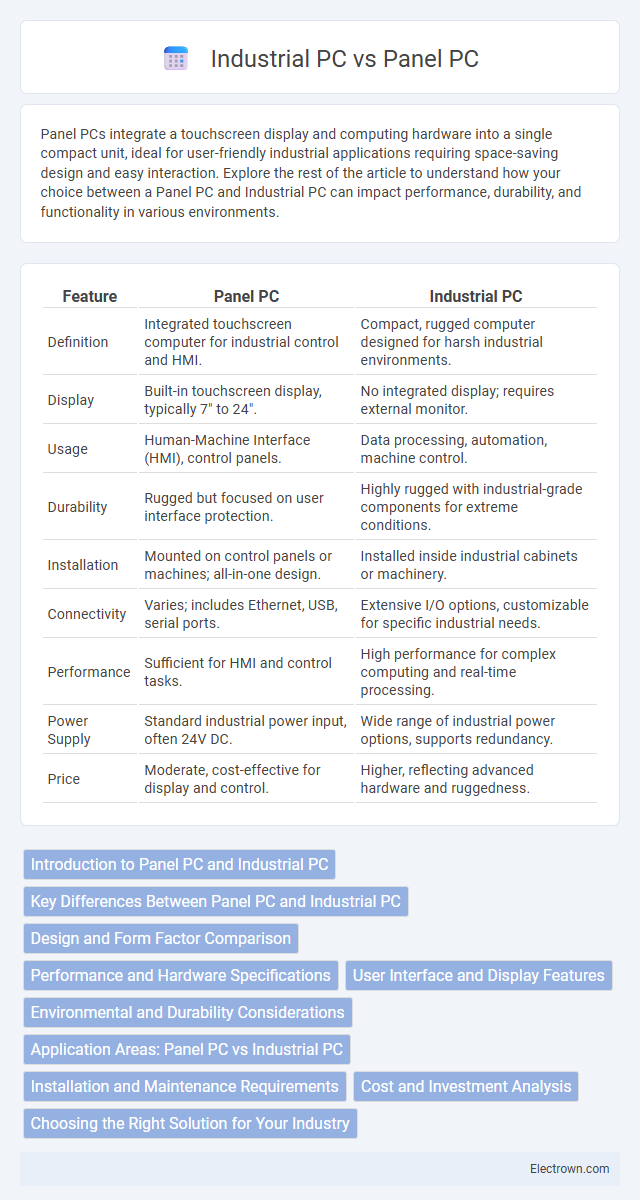

Table of Comparison

| Feature | Panel PC | Industrial PC |

|---|---|---|

| Definition | Integrated touchscreen computer for industrial control and HMI. | Compact, rugged computer designed for harsh industrial environments. |

| Display | Built-in touchscreen display, typically 7" to 24". | No integrated display; requires external monitor. |

| Usage | Human-Machine Interface (HMI), control panels. | Data processing, automation, machine control. |

| Durability | Rugged but focused on user interface protection. | Highly rugged with industrial-grade components for extreme conditions. |

| Installation | Mounted on control panels or machines; all-in-one design. | Installed inside industrial cabinets or machinery. |

| Connectivity | Varies; includes Ethernet, USB, serial ports. | Extensive I/O options, customizable for specific industrial needs. |

| Performance | Sufficient for HMI and control tasks. | High performance for complex computing and real-time processing. |

| Power Supply | Standard industrial power input, often 24V DC. | Wide range of industrial power options, supports redundancy. |

| Price | Moderate, cost-effective for display and control. | Higher, reflecting advanced hardware and ruggedness. |

Introduction to Panel PC and Industrial PC

Panel PCs integrate a touchscreen display with a built-in computer, providing a compact and user-friendly solution for industrial environments. Industrial PCs are rugged, highly customizable computing systems designed to withstand harsh conditions and handle complex automation tasks. Your choice between Panel PC and Industrial PC depends on the specific requirements of interface integration and environmental durability.

Key Differences Between Panel PC and Industrial PC

Panel PCs integrate a touchscreen display and computer components into a single unit designed for user interaction, whereas Industrial PCs are rugged, modular systems built primarily for control and automation tasks without necessarily including user interface hardware. Panel PCs prioritize compact design and ease of use in environments like manufacturing floors, while Industrial PCs offer greater flexibility for customization and expansion to handle complex industrial processes. Your choice depends on whether you need an all-in-one interface or a customizable computing platform for industrial applications.

Design and Form Factor Comparison

Panel PCs feature an integrated touchscreen display combined with computing hardware in a single compact unit, optimizing space efficiency and ease of installation in industrial environments. Industrial PCs typically separate the computing components from the display, offering versatile form factors such as rackmount, wall-mount, or embedded designs to suit various operational needs. The all-in-one design of Panel PCs enhances durability and simplifies cabling, while Industrial PCs provide greater flexibility for customization and upgrade options in complex industrial applications.

Performance and Hardware Specifications

Panel PCs typically integrate a touchscreen display with embedded computing hardware, offering moderate performance suited for user interface applications, often featuring Intel Core i3 to i7 processors, SSD storage, and up to 16GB RAM. Industrial PCs prioritize robust hardware specifications designed for harsh environments, including higher-grade processors like Intel Xeon or AMD Ryzen, expandable RAM beyond 32GB, and enhanced cooling systems for sustained performance. Your choice depends on whether you need a compact all-in-one solution with decent performance or a highly customizable machine optimized for heavy-duty industrial operations.

User Interface and Display Features

Panel PCs integrate touchscreens directly into the display, offering a seamless and compact user interface ideal for space-constrained environments, while Industrial PCs often rely on separate monitors and input devices, providing flexibility for customized setups. High-resolution displays with enhanced brightness and rugged designs characterize Panel PCs, optimizing visibility and durability in harsh industrial settings. Your choice depends on whether an all-in-one user interface with robust touch capabilities or a modular system with scalable display options better suits your operational needs.

Environmental and Durability Considerations

Panel PCs feature integrated touchscreens designed for user interaction in clean, controlled environments, often with moderate protection against dust and moisture (typically IP65 rated). Industrial PCs prioritize extreme durability, offering rugged enclosures with high ingress protection (IP67 or higher), resistance to vibration, shock, and wide temperature operating ranges for harsh industrial settings. Selection depends on environmental exposure, with Industrial PCs favored in heavy-duty applications requiring robust mechanical and environmental resilience.

Application Areas: Panel PC vs Industrial PC

Panel PCs are commonly used in environments requiring integrated user interfaces, such as manufacturing automation, kiosks, and medical devices, where space-saving design and touchscreen capabilities enhance operational efficiency. Industrial PCs are better suited for harsh environments like factories, energy plants, and transportation systems, offering robust durability, expanded I/O options, and high processing power for complex control and monitoring tasks. Both types serve critical roles in industrial automation, but Panel PCs excel in human-machine interaction, while Industrial PCs prioritize rugged performance and scalability.

Installation and Maintenance Requirements

Panel PCs offer streamlined installation with integrated touchscreen displays, reducing the need for separate monitor setups and minimizing cable management complexity in industrial environments. Industrial PCs, typically housed separately from operator interfaces, require additional mounting hardware and more extensive wiring, increasing installation time and maintenance challenges. Maintenance for Panel PCs is generally simpler due to their compact, all-in-one design, while Industrial PCs allow easier component replacement and upgrades but demand more effort for system disassembly and reassembly.

Cost and Investment Analysis

Panel PCs generally offer a lower upfront cost compared to Industrial PCs due to their integrated touchscreen and compact design, reducing the need for additional peripherals. Industrial PCs, while more expensive initially, provide greater scalability and long-term durability, resulting in lower total cost of ownership for demanding applications. Evaluating the investment requires analyzing specific project requirements, maintenance costs, and potential downtime to optimize budget allocation effectively.

Choosing the Right Solution for Your Industry

Panel PCs integrate a touchscreen display and computing unit into a single, space-saving device ideal for user interaction in manufacturing and automation environments. Industrial PCs offer robust, customizable hardware designed to withstand extreme conditions and support complex industrial applications requiring high processing power. Selecting the right solution depends on factors such as environmental durability, processing requirements, and user interface needs specific to your industry's operational demands.

Panel PC vs Industrial PC Infographic

electrown.com

electrown.com