HART Protocol and Foundation Fieldbus offer distinct communication methods for industrial automation, with HART providing backward compatibility and easy integration into existing 4-20 mA systems, while Foundation Fieldbus delivers high-speed digital communication and advanced control capabilities for complex process automation. Explore the article to understand how each protocol fits Your specific industrial communication needs.

Table of Comparison

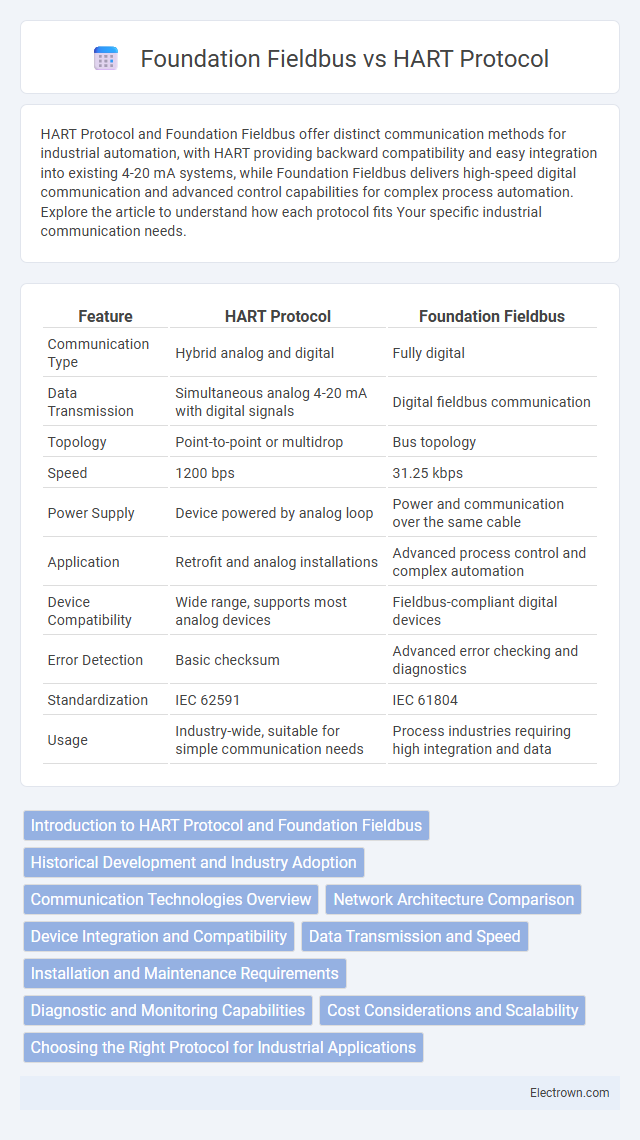

| Feature | HART Protocol | Foundation Fieldbus |

|---|---|---|

| Communication Type | Hybrid analog and digital | Fully digital |

| Data Transmission | Simultaneous analog 4-20 mA with digital signals | Digital fieldbus communication |

| Topology | Point-to-point or multidrop | Bus topology |

| Speed | 1200 bps | 31.25 kbps |

| Power Supply | Device powered by analog loop | Power and communication over the same cable |

| Application | Retrofit and analog installations | Advanced process control and complex automation |

| Device Compatibility | Wide range, supports most analog devices | Fieldbus-compliant digital devices |

| Error Detection | Basic checksum | Advanced error checking and diagnostics |

| Standardization | IEC 62591 | IEC 61804 |

| Usage | Industry-wide, suitable for simple communication needs | Process industries requiring high integration and data |

Introduction to HART Protocol and Foundation Fieldbus

HART Protocol is a hybrid communication technology that combines analog signaling with digital communication, enabling smart devices to transmit data and diagnostic information efficiently in industrial automation. Foundation Fieldbus is a fully digital, two-way communication system designed for real-time distributed control, providing enhanced data accuracy and device interoperability for process industries. Both protocols optimize field device integration but differ in communication methods, complexity, and application scope within control systems.

Historical Development and Industry Adoption

HART Protocol, developed in the 1980s, originated as a hybrid analog-digital communication standard improving existing 4-20 mA instrumentation by enabling digital data exchange without disrupting analog signals. Foundation Fieldbus, introduced in the mid-1990s, represents a fully digital, bus-based system designed for complex process automation, offering enhanced diagnostics and control capabilities. Your choice between these two depends on the legacy systems in place and the advanced integration level required by today's industrial environments.

Communication Technologies Overview

HART Protocol employs a hybrid communication approach combining analog signals with digital messaging over the same wiring, enabling compatibility with traditional 4-20 mA systems and allowing real-time device diagnostics. Foundation Fieldbus uses a fully digital, two-way communication network designed for complex field device integration and enhanced process control, supporting multiple devices on a single network segment. Your choice between these communication technologies should consider network topology, device compatibility, and the level of data complexity required for your automation system.

Network Architecture Comparison

HART Protocol utilizes a hybrid network architecture combining analog and digital signals over 4-20 mA wiring, enabling easy integration with existing instrumentation. Foundation Fieldbus employs a fully digital, bus-based topology allowing multiple devices to communicate over a single pair of wires with peer-to-peer data exchange and advanced diagnostics. The Foundation Fieldbus architecture supports complex control strategies and real-time data sharing, while HART is primarily suited for point-to-point or multi-drop configurations.

Device Integration and Compatibility

HART Protocol offers widespread device integration due to its compatibility with existing 4-20 mA analog infrastructure, enabling seamless communication between smart devices and control systems without extensive rewiring. Foundation Fieldbus provides enhanced device interoperability with its fully digital, multi-drop architecture that allows multiple field devices to communicate on a single cable, optimizing network efficiency and diagnostics. Both protocols support comprehensive device integration, but HART excels in retrofitting legacy systems while Foundation Fieldbus is preferred for new installations requiring advanced digital communication and device interoperability.

Data Transmission and Speed

HART Protocol utilizes a digital signal superimposed on the 4-20mA analog signal, offering data transmission speeds up to 1200 bps, primarily suited for simple device communication and diagnostics. Foundation Fieldbus operates as a fully digital, two-way communication protocol with data rates of 31.25 kbps, enabling faster and more complex automation data exchange. The higher bandwidth and deterministic nature of Foundation Fieldbus support real-time control and multi-variable device integration, outperforming HART in speed and data handling capabilities.

Installation and Maintenance Requirements

HART Protocol requires minimal wiring changes, utilizing existing 4-20 mA analog infrastructure for installation, which simplifies integration and reduces costs. Maintenance involves straightforward device diagnostics accessible via handheld communicators or software, allowing efficient troubleshooting without disrupting operations. Foundation Fieldbus demands specialized digital wiring and power supplies, leading to more complex installation, but provides extensive real-time diagnostics and predictive maintenance capabilities that enhance long-term system reliability.

Diagnostic and Monitoring Capabilities

HART Protocol offers basic diagnostic and monitoring capabilities through device status indicators and limited error messages, mainly supporting point-to-point or simple network configurations. Foundation Fieldbus provides advanced, continuous diagnostics and real-time monitoring with comprehensive device health data, enabling predictive maintenance and reduced downtime in complex, integrated automation systems. The digital nature of Foundation Fieldbus allows seamless integration of detailed diagnostic information across multiple devices, optimizing process control and asset management.

Cost Considerations and Scalability

HART Protocol offers cost-effective implementation by utilizing existing 4-20 mA wiring, minimizing infrastructure expenses, while Foundation Fieldbus requires higher initial investment due to digital cabling and advanced device integration. Scalability favors Foundation Fieldbus with its ability to support complex network topologies and numerous devices on a single segment, enhancing system expansion and automation capabilities. HART's simpler architecture suits smaller or budget-conscious projects, whereas Foundation Fieldbus excels in large-scale industrial environments demanding robust communication and control.

Choosing the Right Protocol for Industrial Applications

HART Protocol excels in hybrid environments by combining analog signals with digital communication, making it suitable for existing 4-20mA instrumentation and offering high compatibility. Foundation Fieldbus provides a fully digital, high-speed network enabling advanced device diagnostics, better control, and reduced wiring costs in complex industrial automation systems. Assess your system requirements, such as integration ease, data needs, and scalability, to determine the optimal protocol for your industrial applications.

HART Protocol vs Foundation Fieldbus Infographic

electrown.com

electrown.com