Slip rings and commutators both serve to transfer electrical signals between stationary and rotating parts, but slip rings provide continuous 360-degree rotation with consistent power transfer, whereas commutators reverse current direction to maintain unidirectional torque in DC machines. Understanding these differences will help you choose the right component for your electrical application--read on to explore their functions, advantages, and uses.

Table of Comparison

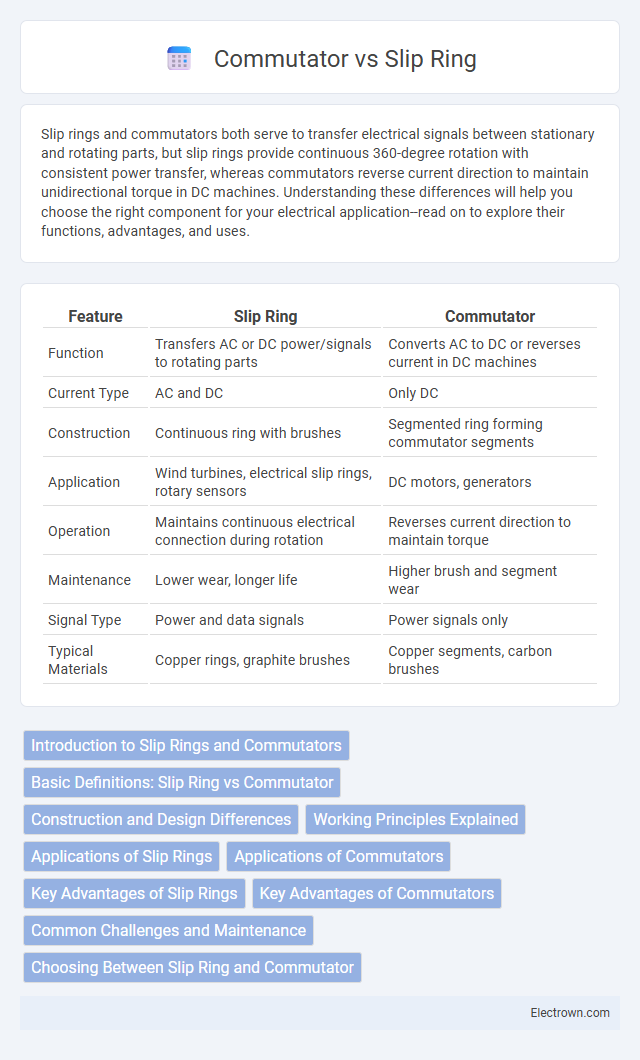

| Feature | Slip Ring | Commutator |

|---|---|---|

| Function | Transfers AC or DC power/signals to rotating parts | Converts AC to DC or reverses current in DC machines |

| Current Type | AC and DC | Only DC |

| Construction | Continuous ring with brushes | Segmented ring forming commutator segments |

| Application | Wind turbines, electrical slip rings, rotary sensors | DC motors, generators |

| Operation | Maintains continuous electrical connection during rotation | Reverses current direction to maintain torque |

| Maintenance | Lower wear, longer life | Higher brush and segment wear |

| Signal Type | Power and data signals | Power signals only |

| Typical Materials | Copper rings, graphite brushes | Copper segments, carbon brushes |

Introduction to Slip Rings and Commutators

Slip rings and commutators are essential components in electrical machines that enable the transfer of electrical signals or power between stationary and rotating parts. Slip rings provide continuous electrical connections for AC circuits by using conductive rings and brushes, ensuring smooth rotation without signal interruption. Commutators, on the other hand, are segmented and used primarily in DC machines to reverse current direction and maintain unidirectional torque, optimizing your machine's performance.

Basic Definitions: Slip Ring vs Commutator

A slip ring is an electromechanical device that allows the transmission of power and electrical signals from a stationary to a rotating structure, commonly used in AC systems. A commutator is a rotary switch in DC machines that reverses the current direction between the rotor and the external circuit, enabling continuous torque production. While slip rings maintain continual transfer without altering current direction, commutators perform mechanical rectification to sustain unidirectional torque.

Construction and Design Differences

Slip rings feature continuous rings and stationary brushes that maintain constant electrical contact, allowing for smooth transmission of power and signals in rotating assemblies. Commutators consist of segmented copper bars insulated from each other, paired with brushes that reverse the current direction to ensure unidirectional torque in DC motors. Your choice between these depends on the need for either uninterrupted power transfer or controlled current commutation within the device.

Working Principles Explained

Slip rings transmit continuous electrical signals and power between stationary and rotating parts by maintaining constant contact through conductive rings and brushes. Commutators function by reversing the direction of current in the armature windings of a DC motor, using segmented rings and brushes to ensure unidirectional torque. The slip ring supports AC signals and smooth rotation, whereas the commutator is essential for DC machines to convert electrical energy to mechanical energy efficiently.

Applications of Slip Rings

Slip rings are widely used in applications requiring continuous rotation while transmitting power and signals, such as wind turbines, electric generators, and rotating radar antennas. Their ability to maintain an uninterrupted electrical connection makes them essential in medical imaging devices like CT scanners and in industrial machinery including rotary tables and cable reels. You can rely on slip rings for efficient energy transfer in robotics, aerospace systems, and marine equipment where smooth rotation and data transmission are critical.

Applications of Commutators

Commutators are primarily used in DC electric motors and generators where they enable the reversal of current direction, ensuring continuous torque and effective operation. They are essential in applications such as electric traction, household appliances like vacuum cleaners and washing machines, and power tools where reliable electrical contact and current switching are critical. Unlike slip rings that maintain constant connection, commutators provide discrete current reversal to suit devices requiring unidirectional rotation and controlled electromagnetic function.

Key Advantages of Slip Rings

Slip rings provide continuous electrical connection between stationary and rotating components, enabling the transmission of power and data without interruption. They offer smooth operation with minimal friction and wear, ensuring long service life and reduced maintenance compared to commutators. Slip rings support higher rotational speeds and deliver efficient signal transfer across multiple circuits, making them ideal for complex electromechanical systems.

Key Advantages of Commutators

Commutators offer precise control of current direction in DC machines, enabling efficient energy conversion and smooth torque delivery. Their ability to maintain continuous electrical contact through segmented design reduces sparking and wear, enhancing durability and performance. You benefit from improved reliability and consistent operation, particularly in applications requiring unidirectional current flow.

Common Challenges and Maintenance

Slip rings and commutators both face common challenges such as wear and tear due to constant friction between brushes and rotating surfaces, leading to electrical noise and signal loss. Proper maintenance involves regular inspection, cleaning to remove dust and carbon buildup, and timely replacement of brushes to ensure consistent conductivity and prevent overheating. Failure to address these issues can result in reduced efficiency, increased downtime, and potential equipment failure in rotary electrical systems.

Choosing Between Slip Ring and Commutator

Choosing between a slip ring and a commutator depends on the type of electrical device and its operational requirements. Slip rings are ideal for AC applications and continuous rotation systems, enabling smooth transmission of power and signals without reversing polarity. Commutators suit DC machines by periodically reversing current direction to maintain torque, making them essential in devices like DC motors and generators.

Slip Ring vs Commutator Infographic

electrown.com

electrown.com