PID control provides precise and continuous adjustment by calculating the error over time, improving system stability and reducing oscillations compared to On-Off control, which simply toggles the output fully on or off. Explore the rest of this article to understand how each method affects Your system's performance and when to choose the best control strategy.

Table of Comparison

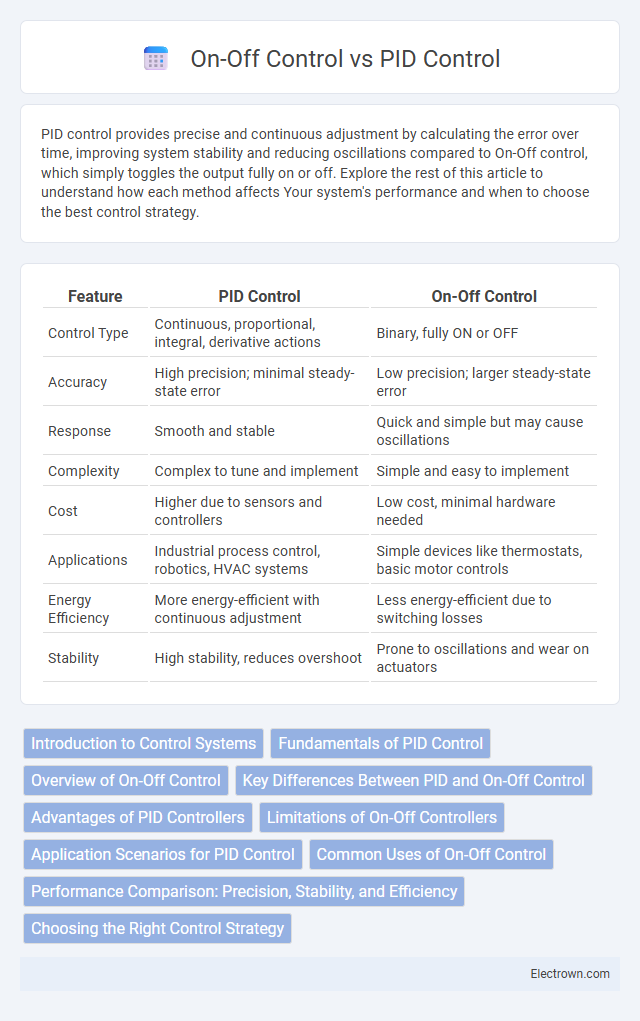

| Feature | PID Control | On-Off Control |

|---|---|---|

| Control Type | Continuous, proportional, integral, derivative actions | Binary, fully ON or OFF |

| Accuracy | High precision; minimal steady-state error | Low precision; larger steady-state error |

| Response | Smooth and stable | Quick and simple but may cause oscillations |

| Complexity | Complex to tune and implement | Simple and easy to implement |

| Cost | Higher due to sensors and controllers | Low cost, minimal hardware needed |

| Applications | Industrial process control, robotics, HVAC systems | Simple devices like thermostats, basic motor controls |

| Energy Efficiency | More energy-efficient with continuous adjustment | Less energy-efficient due to switching losses |

| Stability | High stability, reduces overshoot | Prone to oscillations and wear on actuators |

Introduction to Control Systems

PID control and On-Off control are fundamental techniques in control systems used to regulate processes. PID control continuously adjusts the output based on proportional, integral, and derivative terms to maintain precise and stable system performance. On-Off control operates by switching the output fully on or off, suitable for simple applications but less efficient in handling system variability compared to PID controllers.

Fundamentals of PID Control

PID control relies on proportional, integral, and derivative terms to continuously adjust the output for precise process regulation, minimizing error between setpoint and actual value. Proportional control reacts to the current error, integral addresses accumulated past errors, and derivative predicts future error trends, providing smoother and more accurate control than On-Off control. Your system benefits from PID's ability to reduce oscillations and maintain stable performance in dynamic environments.

Overview of On-Off Control

On-off control operates by switching the output fully on or off according to whether the measured variable crosses a set threshold, making it a simple and cost-effective method for binary control systems. It is commonly used in thermostats, where the system activates heating once the temperature falls below a certain point and deactivates it once the desired temperature is reached. Your choice of on-off control suits applications with tolerable oscillations and where precise regulation is less critical compared to PID control.

Key Differences Between PID and On-Off Control

PID control continuously adjusts the output based on proportional, integral, and derivative terms to minimize error, providing precise and stable system responses. On-Off control operates by switching the output fully on or off when a set threshold is crossed, causing more oscillation and less accuracy. PID controllers are preferred for complex processes requiring fine control, while On-Off is suitable for simple systems with less stringent control demands.

Advantages of PID Controllers

PID controllers offer precise control by continuously adjusting the output based on proportional, integral, and derivative terms, minimizing error and improving system stability. They handle complex dynamic processes more effectively than simple on-off control, reducing overshoot and oscillations. Your system benefits from enhanced accuracy and smoother response, making PID ideal for maintaining consistent process conditions.

Limitations of On-Off Controllers

On-Off controllers exhibit limitations including frequent cycling, which causes wear and shortens the lifespan of mechanical components. Their inability to provide precise control or adapt to changing system dynamics leads to instability and oscillations around the setpoint. Your system performance may suffer from energy inefficiency and inconsistent output due to these inherent constraints.

Application Scenarios for PID Control

PID control is ideal for processes requiring precise and stable regulation, such as temperature control in industrial ovens or speed control in motors where continuous adjustment minimizes oscillations. It excels in applications with dynamic systems, including chemical reactors or robotic motion control, where maintaining setpoints despite disturbances is critical. Your system benefits from PID control when accurate, smooth responses are essential, avoiding the abrupt switching common with on-off control.

Common Uses of On-Off Control

On-off control is commonly used in simple applications such as household thermostats, water heaters, and basic industrial machinery where precise temperature or pressure regulation is not critical. This control method switches devices fully on or off based on setpoint thresholds, making it cost-effective and easy to implement. Your choice for basic systems benefits from its straightforward operation and minimal hardware requirements.

Performance Comparison: Precision, Stability, and Efficiency

PID control offers superior precision by continuously adjusting input based on proportional, integral, and derivative terms, minimizing steady-state error and reducing overshoot compared to On-Off control. Stability in PID systems is enhanced through smooth corrective actions that prevent oscillations common in On-Off control, which switches abruptly between two states. Efficiency is higher in PID control as it optimizes energy use by maintaining output near the desired setpoint, while On-Off control often leads to energy wastage due to frequent cycling and delayed response.

Choosing the Right Control Strategy

Selecting the right control strategy depends on the system's complexity and performance requirements; PID control offers precise, continuous adjustments ideal for processes demanding accuracy and stability. On-off control works well for simple systems with binary states, providing cost-effective and straightforward operation but can lead to oscillations and less smooth control. Evaluating process dynamics, response time, and tolerance for error helps determine whether PID's proportional-integral-derivative adjustments or on-off control's binary switching best suits the application.

PID Control vs On-Off Control Infographic

electrown.com

electrown.com