Differentiating between a flow meter and a level transmitter is essential for accurate fluid measurement and control in industrial processes, as the former measures the volume or mass flow rate of a fluid while the latter determines the fluid level within a container. Understanding these distinctions will help you select the right device for your application; explore the rest of the article to learn more about their functionalities and uses.

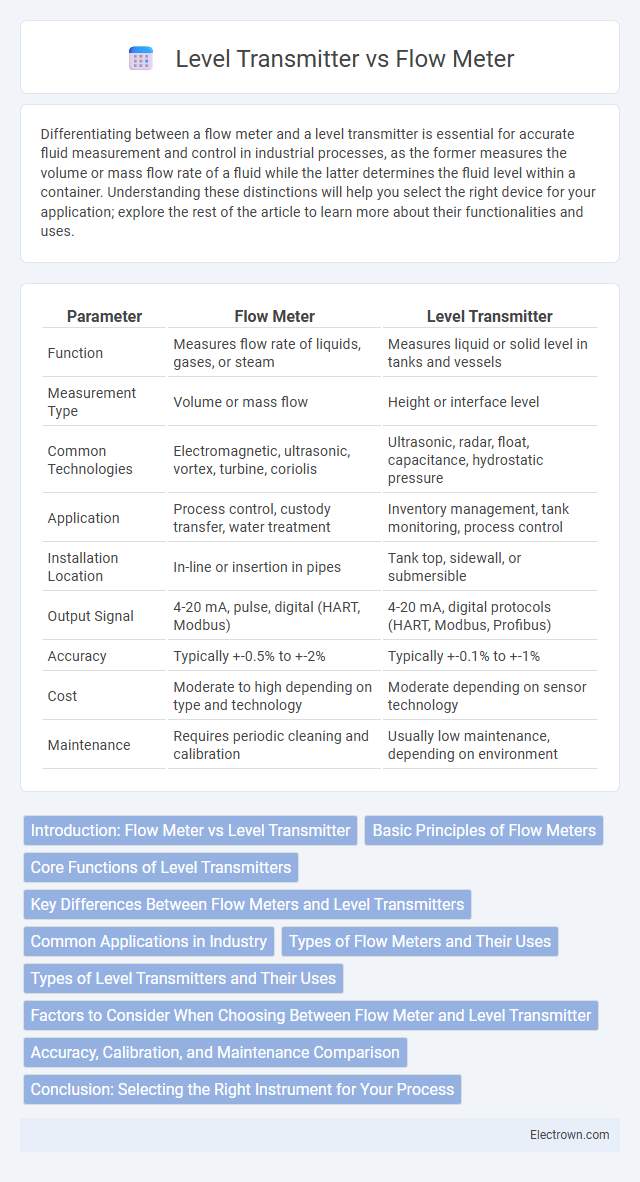

Table of Comparison

| Parameter | Flow Meter | Level Transmitter |

|---|---|---|

| Function | Measures flow rate of liquids, gases, or steam | Measures liquid or solid level in tanks and vessels |

| Measurement Type | Volume or mass flow | Height or interface level |

| Common Technologies | Electromagnetic, ultrasonic, vortex, turbine, coriolis | Ultrasonic, radar, float, capacitance, hydrostatic pressure |

| Application | Process control, custody transfer, water treatment | Inventory management, tank monitoring, process control |

| Installation Location | In-line or insertion in pipes | Tank top, sidewall, or submersible |

| Output Signal | 4-20 mA, pulse, digital (HART, Modbus) | 4-20 mA, digital protocols (HART, Modbus, Profibus) |

| Accuracy | Typically +-0.5% to +-2% | Typically +-0.1% to +-1% |

| Cost | Moderate to high depending on type and technology | Moderate depending on sensor technology |

| Maintenance | Requires periodic cleaning and calibration | Usually low maintenance, depending on environment |

Introduction: Flow Meter vs Level Transmitter

Flow meters measure the volume or mass flow rate of liquids, gases, or steam within a pipe, providing real-time data critical for process control and efficiency. Level transmitters monitor the height or level of liquids, solids, or slurries in tanks and vessels, ensuring accurate inventory and safety management. Both instruments utilize different sensing technologies tailored to their specific measurement needs, such as ultrasonic, radar, or differential pressure methods.

Basic Principles of Flow Meters

Flow meters measure the volume or mass of fluid moving through a pipe by detecting changes in velocity, pressure, or displacement using technologies such as differential pressure, electromagnetic, ultrasonic, or turbine sensing. These devices convert physical flow parameters into electrical signals for monitoring and control in various industrial applications. Understanding these basic principles helps you select the appropriate flow meter for accurate fluid measurement and process optimization.

Core Functions of Level Transmitters

Level transmitters primarily measure the height of liquids or solids within tanks and vessels, providing continuous monitoring to ensure accurate inventory and process control. These devices employ technologies such as ultrasonic, radar, or capacitive sensing to detect level changes with high precision. Your process efficiency and safety significantly benefit from real-time level data, enabling automated control and alert systems.

Key Differences Between Flow Meters and Level Transmitters

Flow meters measure the volume or mass of fluid moving through a pipe, providing data on flow rate, while level transmitters monitor the height or level of liquid within a tank or vessel, ensuring accurate inventory and process control. Flow meters use technologies such as electromagnetic, ultrasonic, or differential pressure principles, whereas level transmitters often rely on radar, ultrasonic, or capacitance methods for precise measurement. The main distinction lies in flow meters tracking dynamic fluid movement versus level transmitters assessing static liquid height, each critical for specific industrial applications.

Common Applications in Industry

Flow meters are widely used in industries such as oil and gas, water treatment, and chemical processing to measure the rate of fluid movement within pipelines, ensuring efficient process control and inventory management. Level transmitters find common applications in storage tanks, silos, and vessels across industries like pharmaceuticals, food and beverage, and wastewater treatment for monitoring liquid or solid material levels to prevent overflow and maintain safety standards. Both devices are essential in industrial automation, enhancing accuracy and operational efficiency by providing critical real-time measurement data.

Types of Flow Meters and Their Uses

Coriolis, electromagnetic, ultrasonic, and turbine flow meters each serve specific industrial applications; Coriolis meters excel in measuring mass flow of viscous fluids, while electromagnetic meters are ideal for conductive liquids like wastewater. Ultrasonic flow meters offer non-intrusive measurement for clean or dirty fluids, commonly used in oil and gas, and turbine meters provide high accuracy for clean, low-viscosity fluids such as water or fuel. Your choice of flow meter depends on fluid type, accuracy requirements, and installation environment, contrasting with level transmitters that primarily measure fluid height or volume within tanks.

Types of Level Transmitters and Their Uses

Magnetostrictive, ultrasonic, radar, and hydrostatic are common types of level transmitters, each suited for specific applications such as tank level measurement, process control, and inventory management. Ultrasonic transmitters use sound waves for non-contact level sensing in liquids, while radar transmitters employ electromagnetic waves for accurate measurement in harsh environments. Hydrostatic transmitters measure liquid pressure to determine level, ideal for open tanks and wells, whereas magnetostrictive types provide high precision in fuel and chemical storage monitoring.

Factors to Consider When Choosing Between Flow Meter and Level Transmitter

Factors to consider when choosing between a flow meter and a level transmitter include the specific measurement requirements such as whether you need to monitor fluid flow rate or liquid level in a tank. Accuracy, installation environment, fluid type, and compatibility with existing process control systems are crucial for selecting the right device. Your choice will impact operational efficiency, so evaluating these factors ensures optimal performance and reliable data for process management.

Accuracy, Calibration, and Maintenance Comparison

Flow meters typically offer high accuracy in measuring fluid velocity, with calibration processes involving standardized test fluids or flow loops to ensure precision, while level transmitters focus on accurate measurement of liquid height using radar, ultrasonic, or hydrostatic methods and require calibration against known reference points. Maintenance for flow meters often includes cleaning sensors and inspecting for wear due to fluid abrasiveness or clogging, whereas level transmitters demand regular checking of sensor integrity and signal output consistency to prevent drift. Both devices depend on routine calibration and maintenance schedules, but flow meters generally involve more complex procedures due to dynamic fluid properties, whereas level transmitters benefit from simpler, less frequent adjustments.

Conclusion: Selecting the Right Instrument for Your Process

Selecting the right instrument between a flow meter and level transmitter depends on whether you need to measure the volume or rate of fluid flow or the liquid level within a vessel. Flow meters provide precise flow rate data critical for process control, while level transmitters deliver accurate liquid level measurements essential for inventory management and safety. Evaluating your process requirements, such as measurement accuracy, application environment, and installation constraints, ensures you choose the optimal device for efficient and reliable operation.

Flow Meter vs Level Transmitter Infographic

electrown.com

electrown.com