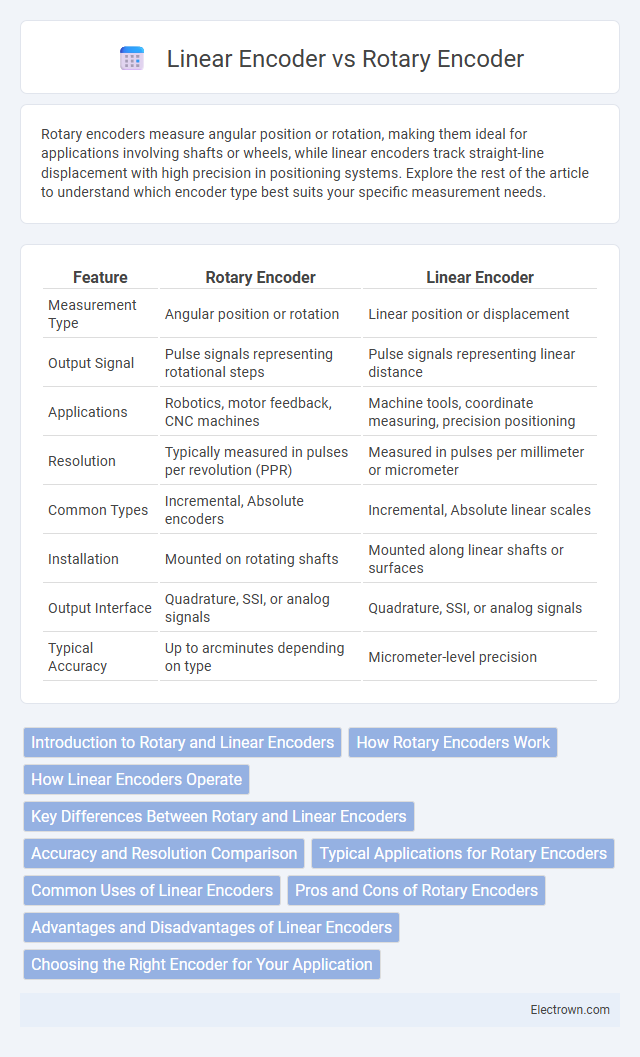

Rotary encoders measure angular position or rotation, making them ideal for applications involving shafts or wheels, while linear encoders track straight-line displacement with high precision in positioning systems. Explore the rest of the article to understand which encoder type best suits your specific measurement needs.

Table of Comparison

| Feature | Rotary Encoder | Linear Encoder |

|---|---|---|

| Measurement Type | Angular position or rotation | Linear position or displacement |

| Output Signal | Pulse signals representing rotational steps | Pulse signals representing linear distance |

| Applications | Robotics, motor feedback, CNC machines | Machine tools, coordinate measuring, precision positioning |

| Resolution | Typically measured in pulses per revolution (PPR) | Measured in pulses per millimeter or micrometer |

| Common Types | Incremental, Absolute encoders | Incremental, Absolute linear scales |

| Installation | Mounted on rotating shafts | Mounted along linear shafts or surfaces |

| Output Interface | Quadrature, SSI, or analog signals | Quadrature, SSI, or analog signals |

| Typical Accuracy | Up to arcminutes depending on type | Micrometer-level precision |

Introduction to Rotary and Linear Encoders

Rotary encoders convert angular position or motion into digital signals, enabling precise measurement of rotational movement in motors and industrial machinery. Linear encoders, by contrast, measure position or displacement along a straight line, offering high accuracy in applications like CNC machines and robotics. Understanding your specific motion measurement needs helps determine whether a rotary or linear encoder is best suited for your project.

How Rotary Encoders Work

Rotary encoders function by converting the angular position or motion of a shaft into digital signals, typically using optical or magnetic sensors to detect rotational changes. These devices emit pulses corresponding to specific increments of rotation, allowing precise measurement of speed, direction, and position. Understanding how rotary encoders work can help you select the right sensor for applications requiring accurate rotational feedback.

How Linear Encoders Operate

Linear encoders operate by detecting the precise position of a moving object along a straight path using optical, magnetic, or capacitive sensing technology. They convert physical displacement into digital signals, enabling highly accurate measurement of linear motion in applications such as CNC machines, automation systems, and metrology instruments. Your choice between rotary and linear encoders depends on whether you need to measure angular rotation or direct linear movement with exact position feedback.

Key Differences Between Rotary and Linear Encoders

Rotary encoders measure rotational position or angular displacement, while linear encoders track linear position or movement along a straight path. Rotary encoders are typically used in applications like motor control, robotics, and rotary valves, whereas linear encoders find applications in CNC machines, coordinate measuring machines, and precision linear motion systems. The key differences lie in their sensing mechanisms, output signals, and installation methods, with rotary encoders using circular scale readings and linear encoders relying on straight scale measurements for position feedback.

Accuracy and Resolution Comparison

Rotary encoders typically offer high resolution with angular measurement precision up to several arcseconds, making them ideal for applications requiring rotational position feedback. Linear encoders provide superior accuracy over short distances, often achieving sub-micron resolution, which is critical for precise linear positioning tasks. Your choice between the two depends on whether you need accurate angular displacement measurement or precise linear position tracking.

Typical Applications for Rotary Encoders

Rotary encoders are commonly used in robotics, CNC machines, and automotive systems to measure angular position, speed, and direction. They provide precise feedback for motor control, robotic arms, and industrial automation where rotational motion needs to be accurately tracked. Typical applications include motor shaft positioning, conveyor speed detection, and steering wheel angle measurement in vehicles.

Common Uses of Linear Encoders

Linear encoders are widely used in CNC machines, coordinate measuring machines (CMMs), and precision positioning systems for their ability to provide accurate linear displacement feedback. These devices are essential in applications requiring high-resolution measurement of linear motion, such as semiconductor manufacturing, robotics, and inspection systems. Their integration enhances the accuracy and repeatability of automated processes, making them critical components in industrial automation and precision engineering.

Pros and Cons of Rotary Encoders

Rotary encoders offer high-resolution angular position feedback and are compact, making them ideal for applications requiring precise rotational measurement such as robotics and industrial automation. Their main drawback is susceptibility to slip and mechanical wear, which can reduce accuracy over time compared to the more stable linear encoders. You should consider rotary encoders when space constraints and angular data are critical, but be aware of maintenance needs and potential inaccuracies in harsh environments.

Advantages and Disadvantages of Linear Encoders

Linear encoders offer precise position measurement directly along a linear scale, providing high accuracy and repeatability ideal for CNC machines and coordinate measuring systems. Their main advantages include immunity to mechanical backlash and the ability to measure absolute position without incremental error accumulation. However, linear encoders can be more expensive, sensitive to contamination or misalignment, and require careful installation compared to rotary encoders that measure angular movement.

Choosing the Right Encoder for Your Application

Selecting the right encoder depends on the specific measurement needs of your application; rotary encoders measure angular position or rotational speed, making them ideal for motors, robotics, and rotary shaft feedback. Linear encoders provide precise position data along a straight path, perfectly suited for CNC machines, automation systems, and linear motion control. Evaluating factors such as resolution, accuracy, installation environment, and mechanical configuration ensures optimal performance and reliability.

Rotary Encoder vs Linear Encoder Infographic

electrown.com

electrown.com