Encoders provide precise digital position feedback by converting mechanical motion into electrical signals, making them ideal for applications requiring accurate and repeatable measurements, while potentiometers offer simpler, cost-effective analog position sensing using variable resistance but with less accuracy and durability. Discover how understanding the differences between encoders and potentiometers can enhance your choice for optimal performance in your projects by reading the full article.

Table of Comparison

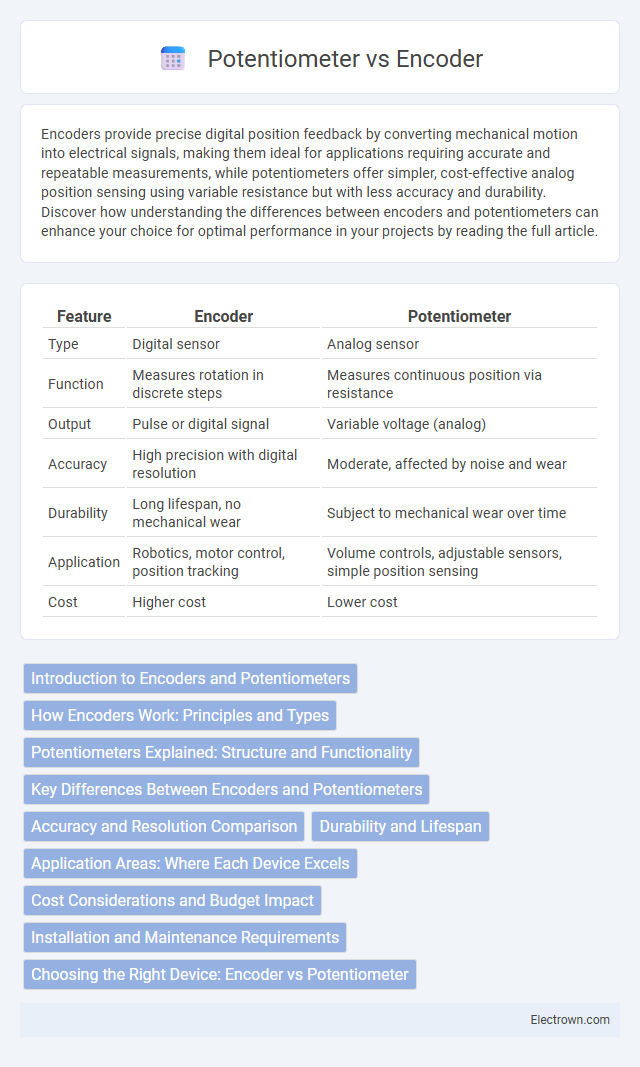

| Feature | Encoder | Potentiometer |

|---|---|---|

| Type | Digital sensor | Analog sensor |

| Function | Measures rotation in discrete steps | Measures continuous position via resistance |

| Output | Pulse or digital signal | Variable voltage (analog) |

| Accuracy | High precision with digital resolution | Moderate, affected by noise and wear |

| Durability | Long lifespan, no mechanical wear | Subject to mechanical wear over time |

| Application | Robotics, motor control, position tracking | Volume controls, adjustable sensors, simple position sensing |

| Cost | Higher cost | Lower cost |

Introduction to Encoders and Potentiometers

Encoders convert mechanical motion into digital signals, enabling precise measurement of position, speed, or direction in automation and robotics. Potentiometers are analog devices that measure angular or linear displacement by varying resistance, commonly used for simple position sensing in control systems. Encoders provide higher accuracy and reliability, while potentiometers offer cost-effective and straightforward position feedback solutions.

How Encoders Work: Principles and Types

Encoders operate by converting mechanical motion into electrical signals through optical, magnetic, or capacitive sensing methods, enabling precise measurement of position, speed, or direction. Incremental encoders generate pulses that correspond to movement distance, while absolute encoders provide a unique digital code for each position, ensuring accurate tracking even after power loss. Your selection between encoders and potentiometers depends on the required resolution, durability, and feedback type for your application.

Potentiometers Explained: Structure and Functionality

Potentiometers consist of a resistive element, a sliding contact (wiper), and three terminals, enabling variable resistance adjustment for voltage control in circuits. The wiper moves along the resistive track, changing the output voltage proportionally, commonly used for volume control and signal tuning. Unlike encoders that provide digital position feedback, potentiometers offer continuous analog input based on mechanical rotation or linear movement.

Key Differences Between Encoders and Potentiometers

Encoders provide digital feedback by converting mechanical motion into electronic signals, enabling precise position and speed measurement, while potentiometers offer analog output based on variable resistance changes due to mechanical movement. Encoders are ideal for applications requiring high accuracy and durability, such as robotics and industrial machinery, whereas potentiometers are simpler, cost-effective solutions suited for basic position sensing and manual control. Your choice depends on the required resolution, environmental conditions, and the nature of the control system.

Accuracy and Resolution Comparison

Encoders provide higher accuracy and resolution compared to potentiometers due to their digital output and ability to detect precise angular positions. Potentiometers rely on mechanical wear and analog signals, which can lead to lower resolution and potential drift over time. Your choice between these devices depends on the required precision and stability for your application.

Durability and Lifespan

Encoders typically offer higher durability and longer lifespan compared to potentiometers due to their non-contact sensing technology, which reduces wear and tear. Potentiometers rely on physical contact between the wiper and resistive element, leading to gradual degradation and limited operational cycles. Your choice between encoder and potentiometer should consider the expected mechanical stress and maintenance requirements to ensure optimal performance over time.

Application Areas: Where Each Device Excels

Encoders excel in application areas requiring precise position, speed, and direction feedback, such as robotics, CNC machines, and industrial automation systems. Potentiometers are ideal for simpler, cost-effective applications like volume controls, joystick position sensing, and light dimmers, where absolute position measurement suffices. Your choice depends on the complexity and accuracy needs of the control system.

Cost Considerations and Budget Impact

Encoders typically have higher upfront costs compared to potentiometers due to their advanced technology and precision components, which can impact the overall budget of a project significantly. Potentiometers are more cost-effective for simple applications, offering reduced initial expenses but potentially higher maintenance costs over time due to wear and tear. Evaluating long-term budget impact, encoders provide better reliability and lower replacement frequency, balancing their initial investment with reduced downtime and maintenance expenses.

Installation and Maintenance Requirements

Encoders require precise alignment and secure mounting to ensure accurate position feedback, often necessitating specialized tools and calibration during installation. Potentiometers offer simpler installation with straightforward mechanical coupling but may need regular cleaning and occasional replacement due to wear from physical contact. Understanding your specific application's durability and precision needs will guide the choice between the low-maintenance potentiometer and the more robust, maintenance-sensitive encoder.

Choosing the Right Device: Encoder vs Potentiometer

Choosing between an encoder and a potentiometer depends on accuracy, durability, and application requirements. Encoders offer precise digital position feedback ideal for automation and robotics, while potentiometers provide analog signals suitable for simple, low-cost angular position sensing. Consider factors like resolution, environmental conditions, and signal type to select the most effective positioning device.

Encoder vs Potentiometer Infographic

electrown.com

electrown.com