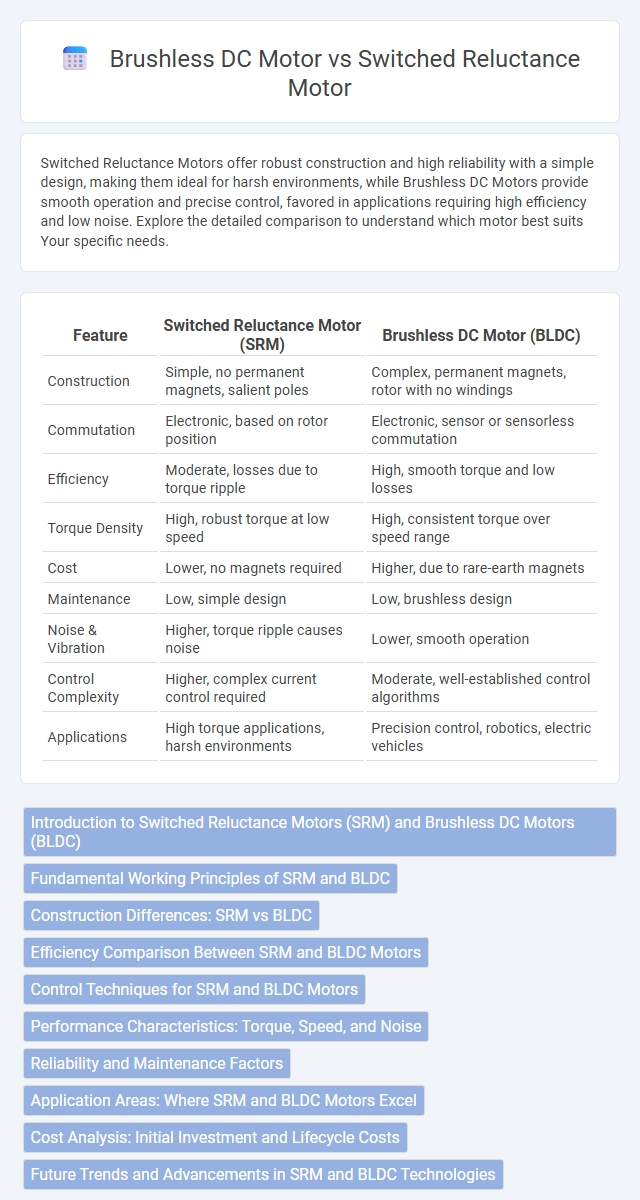

Switched Reluctance Motors offer robust construction and high reliability with a simple design, making them ideal for harsh environments, while Brushless DC Motors provide smooth operation and precise control, favored in applications requiring high efficiency and low noise. Explore the detailed comparison to understand which motor best suits Your specific needs.

Table of Comparison

| Feature | Switched Reluctance Motor (SRM) | Brushless DC Motor (BLDC) |

|---|---|---|

| Construction | Simple, no permanent magnets, salient poles | Complex, permanent magnets, rotor with no windings |

| Commutation | Electronic, based on rotor position | Electronic, sensor or sensorless commutation |

| Efficiency | Moderate, losses due to torque ripple | High, smooth torque and low losses |

| Torque Density | High, robust torque at low speed | High, consistent torque over speed range |

| Cost | Lower, no magnets required | Higher, due to rare-earth magnets |

| Maintenance | Low, simple design | Low, brushless design |

| Noise & Vibration | Higher, torque ripple causes noise | Lower, smooth operation |

| Control Complexity | Higher, complex current control required | Moderate, well-established control algorithms |

| Applications | High torque applications, harsh environments | Precision control, robotics, electric vehicles |

Introduction to Switched Reluctance Motors (SRM) and Brushless DC Motors (BLDC)

Switched Reluctance Motors (SRM) operate on the principle of variable reluctance, featuring a simple construction with salient poles and no permanent magnets, resulting in high reliability and low manufacturing cost. Brushless DC Motors (BLDC) use permanent magnets on the rotor and electronic commutation for precise speed and torque control, making them ideal for applications requiring high efficiency and smooth operation. Your choice between SRM and BLDC depends on factors like cost, control complexity, and performance requirements in specific industrial or automotive applications.

Fundamental Working Principles of SRM and BLDC

Switched Reluctance Motors (SRM) operate based on the principle of magnetic reluctance, where the rotor moves to minimize the magnetic reluctance in the stator's magnetic circuit, leading to torque production without permanent magnets. Brushless DC Motors (BLDC) use electronic commutation to switch current through stator windings, creating a rotating magnetic field that interacts with permanent magnets on the rotor for smooth, efficient motion. Your choice between SRM and BLDC depends on factors like cost, control complexity, and desired efficiency in the application.

Construction Differences: SRM vs BLDC

Switched Reluctance Motors (SRM) feature a simple and robust construction with salient poles on both stator and rotor, lacking permanent magnets or windings on the rotor, which enhances durability and reduces cost. Brushless DC Motors (BLDC) incorporate permanent magnets on the rotor and windings on the stator, enabling smooth and efficient torque generation with electronic commutation. Your choice between SRM and BLDC depends on factors like maintenance preferences, cost constraints, and required performance characteristics.

Efficiency Comparison Between SRM and BLDC Motors

Switched Reluctance Motors (SRMs) offer robust performance with simple construction but typically exhibit lower efficiency than Brushless DC Motors (BLDCs) due to higher torque ripple and magnetic losses. BLDC motors achieve superior efficiency, often exceeding 85-90%, thanks to their permanent magnets and optimized electronic commutation, resulting in smoother operation and reduced energy consumption. For your application, selecting a BLDC motor may maximize energy savings and efficiency, especially in precision control environments.

Control Techniques for SRM and BLDC Motors

Switched Reluctance Motors (SRMs) utilize variable phase excitation control strategies based on rotor position sensors or sensorless estimation to achieve precise torque control and minimize torque ripple. Brushless DC (BLDC) motors employ electronic commutation via Hall-effect sensors or sensorless back-EMF detection for smooth and efficient control of motor phases. Advanced control techniques like PWM modulation and field-oriented control enhance performance in both SRM and BLDC motor drives, optimizing efficiency and dynamic response.

Performance Characteristics: Torque, Speed, and Noise

Switched Reluctance Motors (SRMs) exhibit high torque density and robustness, particularly at low speeds, making them efficient for applications requiring strong starting torque. Brushless DC Motors (BLDCs) offer smoother rotation with higher constant speeds and lower acoustic noise due to their continuous torque production and precise electronic commutation. Your choice should consider that SRMs tend to generate more noise and torque ripple compared to the quieter and more consistent performance of BLDC motors.

Reliability and Maintenance Factors

Switched Reluctance Motors (SRMs) have a simple and robust construction with no brushes or permanent magnets, resulting in higher reliability and low maintenance requirements compared to Brushless DC (BLDC) motors. BLDC motors rely on permanent magnets and electronic commutation, which can lead to increased complexity and potential failure points in harsh environments. The absence of magnets in SRMs also eliminates demagnetization risks, making them better suited for applications demanding long service life and minimal upkeep.

Application Areas: Where SRM and BLDC Motors Excel

Switched Reluctance Motors (SRMs) excel in high-temperature and rugged industrial applications such as mining, aerospace, and heavy-duty automotive sectors due to their simple construction and robustness. Brushless DC Motors (BLDCs) are widely preferred in precision-driven applications including consumer electronics, robotics, and electric vehicles because of their high efficiency, smooth operation, and superior speed control. SRMs are ideal for scenarios requiring high torque at low cost and reliability, whereas BLDCs dominate fields demanding compact size, low noise, and high dynamic performance.

Cost Analysis: Initial Investment and Lifecycle Costs

Switched Reluctance Motors (SRMs) generally have a lower initial investment due to simpler construction and fewer rare materials compared to Brushless DC Motors (BLDCs), which require expensive permanent magnets. Lifecycle costs for SRMs are often reduced by their robustness and lower maintenance needs, while BLDCs may incur higher costs over time due to magnet degradation and necessitated replacements. Your choice should weigh initial budget constraints against long-term efficiency and maintenance expenses linked to each motor type.

Future Trends and Advancements in SRM and BLDC Technologies

Switched Reluctance Motors (SRMs) are gaining traction with advancements in power electronics and sensorless control algorithms, enhancing efficiency and reducing acoustic noise for electric vehicle applications. Brushless DC Motors (BLDCs) continue to benefit from innovations in rare-earth magnet materials, enabling higher power density and improved thermal management in aerospace and robotics. Emerging trends in both SRM and BLDC technologies include integration with IoT-enabled smart controllers and adoption of wide bandgap semiconductors to boost performance and reliability in industrial automation.

Switched Reluctance Motor vs Brushless DC Motor Infographic

electrown.com

electrown.com