AC contactors are specifically designed to control alternating current circuits, providing efficient switching and protection for AC motors and electrical loads, while DC contactors handle direct current applications with specialized arc-quenching techniques to manage the constant current flow. Understanding the differences between AC and DC contactors will help you select the right device for your electrical system needs--explore the rest of the article to learn more.

Table of Comparison

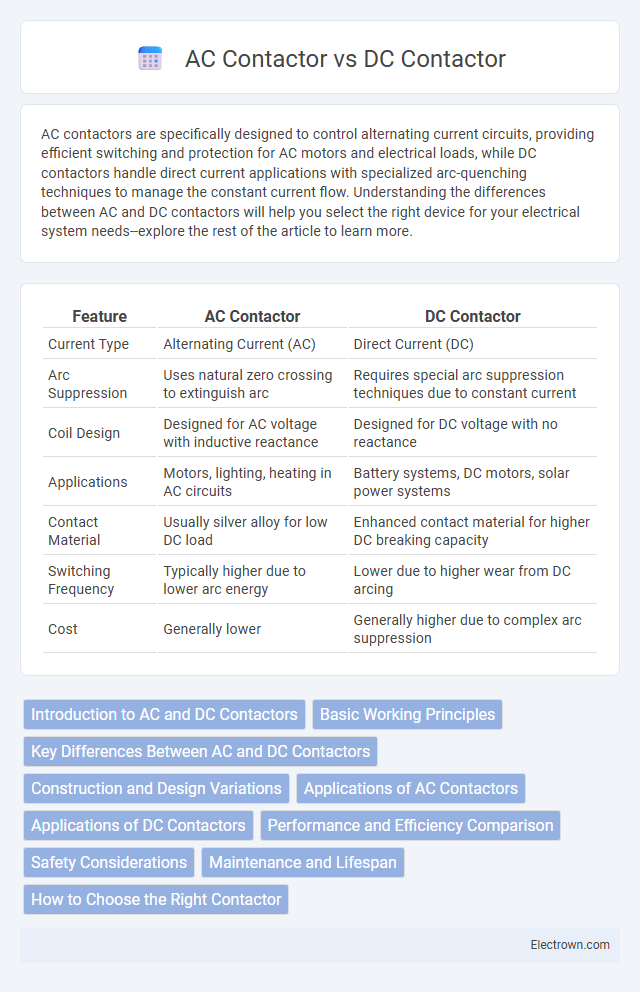

| Feature | AC Contactor | DC Contactor |

|---|---|---|

| Current Type | Alternating Current (AC) | Direct Current (DC) |

| Arc Suppression | Uses natural zero crossing to extinguish arc | Requires special arc suppression techniques due to constant current |

| Coil Design | Designed for AC voltage with inductive reactance | Designed for DC voltage with no reactance |

| Applications | Motors, lighting, heating in AC circuits | Battery systems, DC motors, solar power systems |

| Contact Material | Usually silver alloy for low DC load | Enhanced contact material for higher DC breaking capacity |

| Switching Frequency | Typically higher due to lower arc energy | Lower due to higher wear from DC arcing |

| Cost | Generally lower | Generally higher due to complex arc suppression |

Introduction to AC and DC Contactors

AC contactors are electromechanical switches designed to control alternating current circuits, commonly used in residential and industrial applications to manage motors and lighting systems. DC contactors, in contrast, are specialized for direct current circuits, providing reliable switching where steady voltage flow is critical, such as in battery-operated equipment and electric vehicles. Understanding the differences in coil design, arc suppression, and load compatibility can help you select the appropriate contactor for your electrical system's specific AC or DC requirements.

Basic Working Principles

AC contactors operate by using an electromagnetic coil that creates a magnetic field when alternating current passes through, causing the contactor to open or close electrical circuits. DC contactors function similarly but require specific design considerations, such as stronger springs or magnetic blowouts, to interrupt direct current and prevent arcing due to the continuous flow of electricity. Understanding the basic working principles of these devices helps you select the appropriate contactor based on the type of current in your electrical system.

Key Differences Between AC and DC Contactors

AC contactors are designed to handle alternating current, featuring coil windings optimized for AC voltage and incorporating shading coils to prevent chatter during zero crossings. DC contactors operate with direct current, requiring stronger magnetic fields without zero crossing points, thus using specially designed coils and contacts to withstand continuous arcing. The key difference lies in coil design and arc suppression techniques, making AC contactors suitable for AC circuits while DC contactors are essential for reliable switching in DC applications.

Construction and Design Variations

AC contactors feature a laminated iron core and shading coils to reduce noise and prevent chatter caused by alternating current, while DC contactors use a solid core and a stronger spring mechanism to counteract the continuous magnetic flux and maintain contact stability. The coil design in AC contactors allows for magnetic flux to alternate, necessitating specific dampening components, whereas DC contactors require a more robust coil capable of handling constant magnetic force without overheating. Contact materials and arc suppression techniques also differ; AC contactors rely on the natural zero crossing of AC to extinguish arcs, while DC contactors incorporate specialized arc chutes or blowout coils to safely interrupt the steady current flow.

Applications of AC Contactors

AC contactors are widely used in industrial motor control, lighting systems, and HVAC applications due to their ability to handle alternating current with high efficiency. They enable remote switching of electrical loads in automation systems, ensuring safe and reliable operation in manufacturing plants and commercial buildings. Your choice of contactor depends on the specific current type and load requirements, emphasizing the importance of selecting AC contactors for AC-powered equipment.

Applications of DC Contactors

DC contactors are primarily used in electric vehicle systems, renewable energy storage solutions, and industrial battery management to safely control high-current DC loads. Their robust design ensures reliable switching of direct current, which is essential for applications such as solar power inverters, electric traction motors, and DC-powered automation systems. These contactors prevent arcing and provide long operational life under harsh electrical conditions, making them indispensable in DC circuit control.

Performance and Efficiency Comparison

AC contactors are designed to handle alternating current with minimal power loss, offering high efficiency in switching AC loads due to features like arc suppression and enhanced coil insulation. DC contactors require more robust arc quenching mechanisms to manage the continuous current flow, which can lead to slightly lower efficiency and increased wear over time compared to AC contactors. Performance differences are evident in response times and durability, with AC contactors being optimized for faster operation in AC circuits, whereas DC contactors excel in steady, high-current DC applications despite generally higher energy consumption.

Safety Considerations

AC contactors and DC contactors differ significantly in safety considerations due to the distinct characteristics of alternating current and direct current. AC contactors benefit from the natural zero-crossing of AC waveform, which aids arc extinguishing, reducing the risk of contact welding and enhancing operator safety. In contrast, DC contactors require specialized arc suppression techniques since DC maintains a constant current flow, increasing the risk of persistent arcing and necessitating robust insulation and contact materials to ensure safe operation.

Maintenance and Lifespan

AC contactors typically require less frequent maintenance due to their simpler arc-quenching methods, resulting in extended operational lifespan under standard conditions. DC contactors experience more wear because of continuous arc formation during switching, necessitating regular inspection and replacement of contact points to maintain performance. Proper maintenance and environmental factors can significantly influence the durability and reliability of both AC and DC contactors.

How to Choose the Right Contactor

Choosing the right contactor depends on your electrical system's current type, voltage rating, and application requirements. AC contactors are designed to handle alternating current with features like arc suppression and coil efficiency, while DC contactors manage direct current with enhanced arc interruption and higher endurance for steady loads. Understanding your load characteristics and control circuit specifications ensures you select a contactor that maximizes reliability and operational safety for your equipment.

AC Contactor vs DC Contactor Infographic

electrown.com

electrown.com