HMI and SCADA systems both play critical roles in industrial automation, with HMI focusing on user interfaces for monitoring and control, while SCADA encompasses broader supervisory control and data acquisition across multiple sites. Discover how understanding these differences can optimize Your industrial processes by reading the rest of this article.

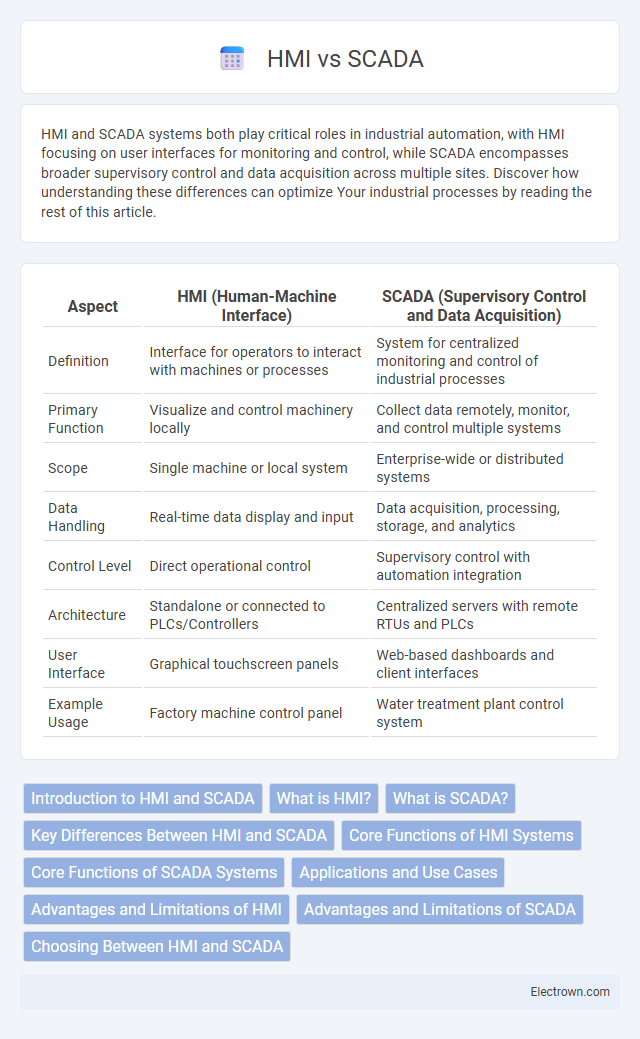

Table of Comparison

| Aspect | HMI (Human-Machine Interface) | SCADA (Supervisory Control and Data Acquisition) |

|---|---|---|

| Definition | Interface for operators to interact with machines or processes | System for centralized monitoring and control of industrial processes |

| Primary Function | Visualize and control machinery locally | Collect data remotely, monitor, and control multiple systems |

| Scope | Single machine or local system | Enterprise-wide or distributed systems |

| Data Handling | Real-time data display and input | Data acquisition, processing, storage, and analytics |

| Control Level | Direct operational control | Supervisory control with automation integration |

| Architecture | Standalone or connected to PLCs/Controllers | Centralized servers with remote RTUs and PLCs |

| User Interface | Graphical touchscreen panels | Web-based dashboards and client interfaces |

| Example Usage | Factory machine control panel | Water treatment plant control system |

Introduction to HMI and SCADA

Human-Machine Interface (HMI) and Supervisory Control and Data Acquisition (SCADA) are integral components in industrial automation for real-time monitoring and control. HMI provides operators with graphical visualization and interaction with machines, while SCADA systems integrate HMI with centralized data acquisition, processing, and control across multiple sites. Combining HMI's user interface capabilities with SCADA's comprehensive data management optimizes operational efficiency and decision-making in industrial environments.

What is HMI?

HMI (Human-Machine Interface) is a user interface that connects operators to industrial machines, allowing real-time monitoring and control of processes. It translates complex data from equipment into visual displays like touchscreens, enabling efficient interaction and decision-making. Your ability to oversee and manage industrial systems improves significantly with a well-designed HMI.

What is SCADA?

SCADA (Supervisory Control and Data Acquisition) is an advanced industrial control system that monitors and manages large-scale processes across multiple locations in real-time. It collects data from sensors and devices, enabling centralized control and analysis to optimize operational efficiency and safety. Your facility benefits from SCADA by gaining comprehensive oversight and automated decision-making capabilities, surpassing the more localized interface functions of HMI (Human-Machine Interface).

Key Differences Between HMI and SCADA

HMI (Human-Machine Interface) primarily serves as the user interface for operators to control and monitor individual machines or processes, providing real-time data visualization. SCADA (Supervisory Control and Data Acquisition) encompasses a broader system that collects data from multiple HMIs and remote devices to enable centralized monitoring and control across entire industrial plants or infrastructure. Your choice depends on the scale and complexity of the operation, with HMI suited for localized control and SCADA designed for comprehensive supervisory control and data acquisition.

Core Functions of HMI Systems

HMI systems primarily serve as the human-machine interface, enabling operators to monitor and control industrial processes through graphical displays and real-time data visualization. Core functions include data input, system status monitoring, alarm management, and device control, allowing you to interact directly with machinery for efficient operation. Compared to SCADA, which focuses on data acquisition and system-wide supervision, HMI emphasizes localized control and user-friendly interaction at the equipment level.

Core Functions of SCADA Systems

SCADA systems primarily focus on real-time data acquisition, process monitoring, and centralized control across large-scale industrial operations, enabling efficient management of multiple remote sites. Core functions include collecting sensor data, analyzing system performance, and automatically triggering alarms or control actions to maintain operational safety and efficiency. Your industrial automation setup benefits from SCADA's ability to integrate data visualization with historical trend analysis, ensuring proactive decision-making and optimized process control.

Applications and Use Cases

Human-Machine Interface (HMI) systems are primarily used for direct control and monitoring of individual machines or processes, enabling operators to interact with real-time data through graphical displays. SCADA (Supervisory Control and Data Acquisition) systems manage large-scale industrial operations by collecting data from multiple HMI units, sensors, and controllers across dispersed locations for centralized monitoring and control. Common applications of HMI include machinery control panels in manufacturing plants, while SCADA is widely utilized in utilities management, such as water treatment, electrical grid monitoring, and oil pipeline supervision.

Advantages and Limitations of HMI

Human-Machine Interface (HMI) offers real-time data visualization, intuitive control panels, and ease of use for operators, enhancing quick decision-making in industrial environments. Its limitations include restricted scalability and insufficient historical data analysis compared to SCADA systems, making it less suitable for complex, large-scale operations. HMI excels in local control and monitoring but lacks the comprehensive supervisory capabilities found in SCADA, such as remote access and multi-site integration.

Advantages and Limitations of SCADA

SCADA systems excel in providing comprehensive real-time monitoring and control across wide geographical areas, supporting complex industrial processes with centralized data collection and historical analysis. Their scalability and integration with various sensors and devices enable enhanced operational efficiency and predictive maintenance. However, SCADA systems face limitations such as vulnerability to cyberattacks, high implementation costs, and dependence on network reliability, which can impact system responsiveness and data accuracy.

Choosing Between HMI and SCADA

Choosing between HMI and SCADA depends on the scale and complexity of the industrial control system. HMI (Human-Machine Interface) typically focuses on operator interaction with individual machines or processes, offering real-time data visualization and control. SCADA (Supervisory Control and Data Acquisition) provides a comprehensive system for monitoring and controlling multiple remote sites or entire plants, integrating data collection, alarms, and advanced analytics for optimized decision-making.

HMI vs SCADA Infographic

electrown.com

electrown.com