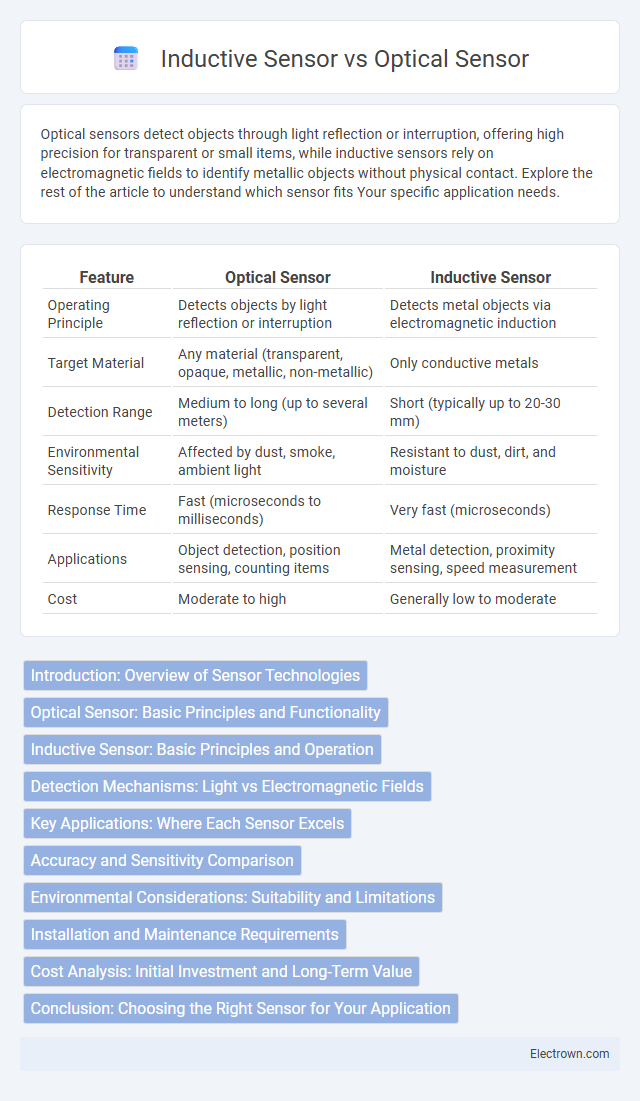

Optical sensors detect objects through light reflection or interruption, offering high precision for transparent or small items, while inductive sensors rely on electromagnetic fields to identify metallic objects without physical contact. Explore the rest of the article to understand which sensor fits Your specific application needs.

Table of Comparison

| Feature | Optical Sensor | Inductive Sensor |

|---|---|---|

| Operating Principle | Detects objects by light reflection or interruption | Detects metal objects via electromagnetic induction |

| Target Material | Any material (transparent, opaque, metallic, non-metallic) | Only conductive metals |

| Detection Range | Medium to long (up to several meters) | Short (typically up to 20-30 mm) |

| Environmental Sensitivity | Affected by dust, smoke, ambient light | Resistant to dust, dirt, and moisture |

| Response Time | Fast (microseconds to milliseconds) | Very fast (microseconds) |

| Applications | Object detection, position sensing, counting items | Metal detection, proximity sensing, speed measurement |

| Cost | Moderate to high | Generally low to moderate |

Introduction: Overview of Sensor Technologies

Optical sensors use light to detect the presence, distance, or properties of an object by measuring changes in light intensity or reflection, offering high precision in various industrial applications. Inductive sensors detect metallic objects through electromagnetic fields without physical contact, making them ideal for harsh environments or metal detection tasks. Understanding the strengths of optical versus inductive sensors helps optimize your selection for specific automation or detection needs.

Optical Sensor: Basic Principles and Functionality

Optical sensors operate by detecting changes in light intensity, reflection, or interruption using components such as LEDs and photodetectors to sense objects or measure distance accurately. These sensors excel in applications requiring non-contact detection and high precision, relying on the modulation of light signals to provide real-time feedback. Your choice of an optical sensor offers advantages in detecting transparent or small objects where inductive sensors, which depend on electromagnetic fields and metal targets, may fall short.

Inductive Sensor: Basic Principles and Operation

Inductive sensors operate based on the principles of electromagnetic induction, detecting metallic objects without physical contact by generating an alternating magnetic field via a coil. When a metal target enters this magnetic field, eddy currents are induced, causing changes in the sensor's oscillation amplitude, which triggers the switching output. These sensors are highly reliable in harsh environments, resistant to dirt, oil, and moisture, making them ideal for industrial automation applications requiring precise metal detection.

Detection Mechanisms: Light vs Electromagnetic Fields

Optical sensors detect objects by emitting and receiving light, using variations in light intensity, reflection, or interruption to identify targets. Inductive sensors operate by generating electromagnetic fields and detecting changes caused by metallic objects entering this field, making them ideal for metal detection. The fundamental difference lies in optical sensors relying on light-based detection, while inductive sensors utilize electromagnetic field variations for sensing.

Key Applications: Where Each Sensor Excels

Optical sensors excel in applications requiring precise object detection, distance measurement, and presence sensing in industries like manufacturing, packaging, and automation, where non-contact sensing is crucial. Inductive sensors are ideal for detecting metallic objects in harsh environments such as automotive assembly, metal fabrication, and robotics, offering robust performance despite dust, dirt, or oil. Choosing the right sensor depends on your need for material-specific detection and environmental conditions.

Accuracy and Sensitivity Comparison

Optical sensors offer higher accuracy and sensitivity by detecting changes in light intensity or reflection, making them ideal for precise object detection and measurement. Inductive sensors rely on electromagnetic fields to detect metal objects, providing reliable operation but generally lower sensitivity to small or non-metallic targets. Your choice depends on the need for fine detail detection with optical sensors or robust metal object sensing with inductive sensors.

Environmental Considerations: Suitability and Limitations

Optical sensors excel in clean, dry environments as dust, dirt, and moisture can interfere with their light-based detection, limiting effectiveness in harsh or dirty conditions. Inductive sensors perform reliably in environments with dirt, oil, and metal contaminants due to their electromagnetic field operation, but they can only detect metallic objects, restricting their versatility. Selecting between optical and inductive sensors depends heavily on environmental factors such as presence of contaminants and target material properties.

Installation and Maintenance Requirements

Optical sensors require precise alignment during installation to ensure accurate light detection and may need regular cleaning to prevent dust or dirt from obstructing the sensor's optics. Inductive sensors are simpler to install due to their tolerance of misalignment and robust design, requiring minimal maintenance as they operate without contact and are resistant to contaminants like dust and oil. Both sensor types benefit from an environment-appropriate setup, but inductive sensors generally offer lower maintenance demands in industrial applications.

Cost Analysis: Initial Investment and Long-Term Value

Optical sensors generally have a higher initial investment due to advanced components like light emitters and photodetectors, whereas inductive sensors tend to be more cost-effective upfront with simpler coil-based designs. Over the long term, optical sensors may offer greater value through higher precision and reduced wear, lowering maintenance costs and downtime. Your choice depends on balancing initial budget constraints against desired sensor performance and life cycle expenses.

Conclusion: Choosing the Right Sensor for Your Application

Optical sensors excel in detecting transparent, reflective, or small objects with high precision, making them ideal for applications requiring longer sensing ranges and non-contact detection. Inductive sensors offer robust performance in harsh environments, reliably detecting metal targets through solid barriers with high resistance to dust, dirt, and moisture. Selecting the right sensor depends on factors such as target material, environmental conditions, sensing distance, and required precision to ensure optimal performance and longevity.

Optical Sensor vs Inductive Sensor Infographic

electrown.com

electrown.com