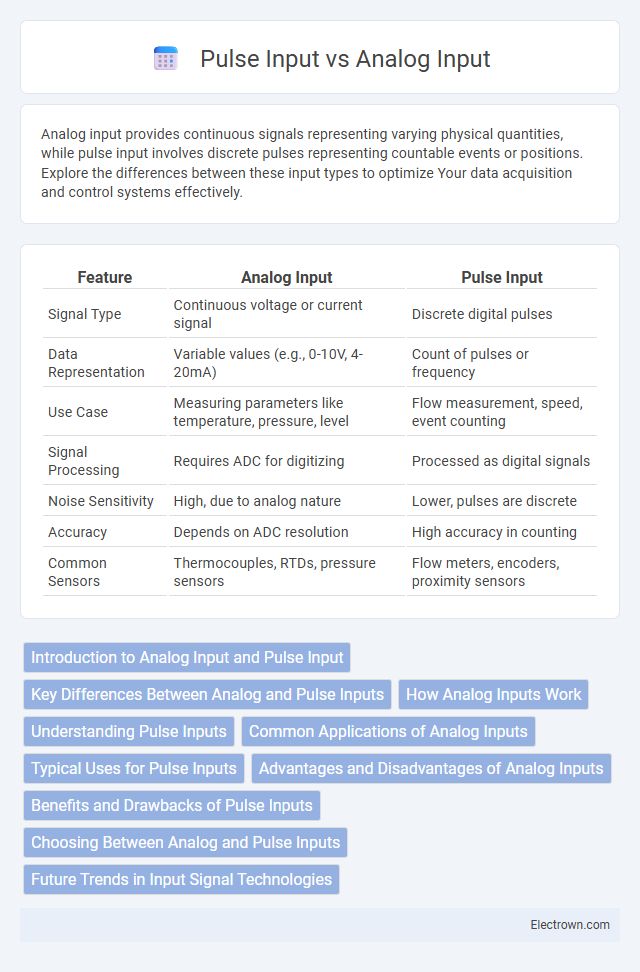

Analog input provides continuous signals representing varying physical quantities, while pulse input involves discrete pulses representing countable events or positions. Explore the differences between these input types to optimize Your data acquisition and control systems effectively.

Table of Comparison

| Feature | Analog Input | Pulse Input |

|---|---|---|

| Signal Type | Continuous voltage or current signal | Discrete digital pulses |

| Data Representation | Variable values (e.g., 0-10V, 4-20mA) | Count of pulses or frequency |

| Use Case | Measuring parameters like temperature, pressure, level | Flow measurement, speed, event counting |

| Signal Processing | Requires ADC for digitizing | Processed as digital signals |

| Noise Sensitivity | High, due to analog nature | Lower, pulses are discrete |

| Accuracy | Depends on ADC resolution | High accuracy in counting |

| Common Sensors | Thermocouples, RTDs, pressure sensors | Flow meters, encoders, proximity sensors |

Introduction to Analog Input and Pulse Input

Analog input measures continuous signals such as voltage or current to represent real-world variables like temperature or pressure. Pulse input counts discrete pulses, often generated by devices like flow meters or encoders, to quantify events or rotations. Both input types are essential for accurate data acquisition in automation and control systems, optimizing measurement precision based on the sensor output format.

Key Differences Between Analog and Pulse Inputs

Analog inputs measure continuous signals that vary smoothly over time, often representing parameters like temperature, pressure, or voltage with values within a specified range. Pulse inputs, conversely, count discrete pulses or events, frequently used for monitoring flow rates, RPM, or frequency where the signal consists of on/off states. The primary difference lies in data type: analog inputs capture varying magnitudes, while pulse inputs record quantized event counts or frequencies.

How Analog Inputs Work

Analog inputs measure continuous signals by converting physical quantities like temperature or pressure into voltage or current values that your control system can interpret. These signals are typically processed through an analog-to-digital converter (ADC), which transforms the continuous signal into a digital format for precise monitoring and control. Understanding how analog inputs work is crucial for accurately capturing real-world conditions in automation and instrumentation applications.

Understanding Pulse Inputs

Pulse inputs measure discrete signals by counting the number of pulses within a set time, essential for applications like flow measurement and speed monitoring. Unlike analog inputs that interpret continuous voltage or current signals, pulse inputs provide precise event quantification and timing accuracy. Devices such as flow meters, tachometers, and digital encoders primarily rely on pulse input counting to convert physical phenomena into digital data for accurate monitoring.

Common Applications of Analog Inputs

Analog inputs are widely used in industrial automation for monitoring temperature, pressure, and flow rates by converting real-world signals into readable electrical values. They are essential in process control systems where continuous data measurement allows for precise adjustments and improved system performance. Your control system relies on analog inputs to capture exact sensor readings, enabling accurate and real-time monitoring of physical parameters.

Typical Uses for Pulse Inputs

Pulse inputs are commonly used in flow measurement applications such as water, gas, and electricity meters, where accurate counting of discrete events or pulses corresponding to volume or energy consumption is critical. These inputs facilitate precise monitoring of rotating equipment speeds and frequency-based signals in industrial automation systems. Pulse inputs enable efficient data acquisition for pulse-generating sensors like encoders, flowmeters, and digital switches, ensuring reliable and time-sensitive event detection.

Advantages and Disadvantages of Analog Inputs

Analog inputs provide continuous signal measurement, enabling precise monitoring of variables such as temperature, pressure, and voltage with high resolution. They offer simplicity in interfacing with sensors and support a wide dynamic range but are susceptible to noise and signal degradation over long distances. Calibration and signal conditioning complexities present challenges, requiring careful design to maintain accuracy and reliability in industrial and automation systems.

Benefits and Drawbacks of Pulse Inputs

Pulse inputs provide high-resolution signal measurement and excellent noise immunity, making them ideal for applications requiring precise event counting or speed detection. However, pulse inputs can be limited by maximum frequency thresholds and susceptibility to signal distortion if proper filtering and shielding are not implemented. The benefits include accurate digital signal processing, while drawbacks involve complexity in handling high-frequency pulses and potential latency issues.

Choosing Between Analog and Pulse Inputs

Choosing between analog input and pulse input depends on the nature of the measurement and application requirements. Analog inputs are ideal for continuous signals like temperature or pressure, providing precise and variable data readings. Pulse inputs suit counting or frequency measurements, such as flow rates or event occurrences, where discrete signals represent increments or cycles.

Future Trends in Input Signal Technologies

Future trends in input signal technologies emphasize the convergence of analog input and pulse input methods through advanced sensor integration and digital signal processing (DSP). Emerging applications prioritize high-resolution data acquisition from analog sensors combined with precise timing and counting capabilities inherent in pulse inputs, facilitating improved accuracy in industrial automation and IoT systems. Innovations in machine learning algorithms further enhance real-time interpretation of complex signal patterns, driving smarter and more adaptive input systems.

Analog Input vs Pulse Input Infographic

electrown.com

electrown.com