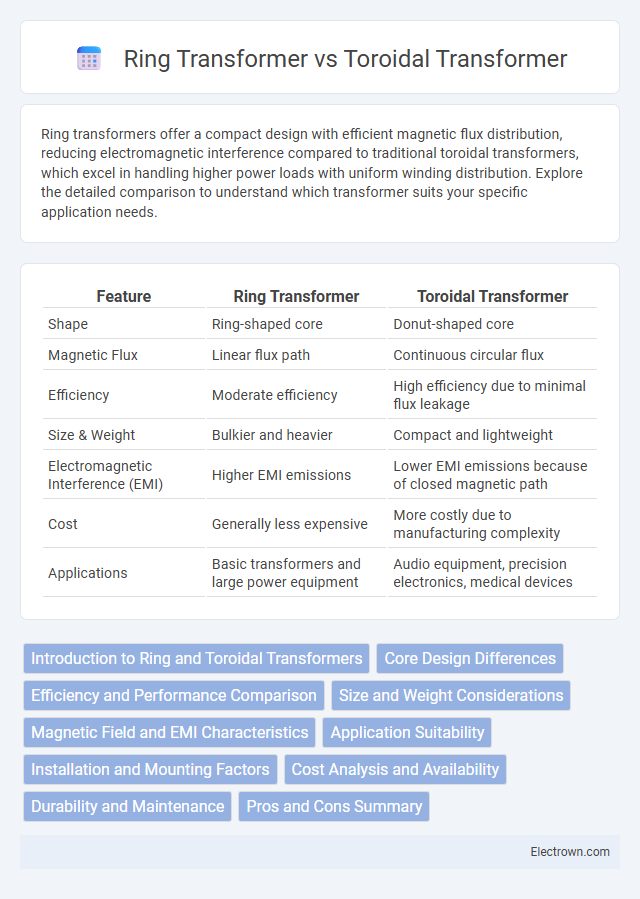

Ring transformers offer a compact design with efficient magnetic flux distribution, reducing electromagnetic interference compared to traditional toroidal transformers, which excel in handling higher power loads with uniform winding distribution. Explore the detailed comparison to understand which transformer suits your specific application needs.

Table of Comparison

| Feature | Ring Transformer | Toroidal Transformer |

|---|---|---|

| Shape | Ring-shaped core | Donut-shaped core |

| Magnetic Flux | Linear flux path | Continuous circular flux |

| Efficiency | Moderate efficiency | High efficiency due to minimal flux leakage |

| Size & Weight | Bulkier and heavier | Compact and lightweight |

| Electromagnetic Interference (EMI) | Higher EMI emissions | Lower EMI emissions because of closed magnetic path |

| Cost | Generally less expensive | More costly due to manufacturing complexity |

| Applications | Basic transformers and large power equipment | Audio equipment, precision electronics, medical devices |

Introduction to Ring and Toroidal Transformers

Ring transformers feature a circular core molded into a ring shape, optimizing magnetic flux distribution and minimizing electromagnetic interference for compact, efficient power conversion. Toroidal transformers use a doughnut-shaped core made of continuous steel strip, which provides high efficiency, low noise, and reduced stray magnetic fields essential for sensitive electronic equipment. Your choice between these depends on space constraints, efficiency needs, and noise reduction priorities in your electrical design.

Core Design Differences

Ring transformers feature a core made from a continuous ring of laminated steel, which provides uniform magnetic flux distribution and reduces electromagnetic interference. Toroidal transformers use a doughnut-shaped core, typically made from a strip of silicon steel wound into a toroid, resulting in lower core losses and higher efficiency due to minimized leakage flux. The core design differences influence winding arrangements, with ring transformers favoring axial winding and toroidal transformers utilizing a circular winding around the toroid's circumference.

Efficiency and Performance Comparison

Ring transformers generally offer higher efficiency due to their compact core design, which minimizes energy losses and enhances magnetic flux distribution. Toroidal transformers provide superior performance with reduced electromagnetic interference and lower audible hum, making them ideal for sensitive electronic applications. When choosing your transformer, consider that ring types excel in efficiency while toroidal types deliver consistent performance and quieter operation.

Size and Weight Considerations

Ring transformers typically offer a compact and lightweight design, making them ideal for applications where space and weight are critical factors. Toroidal transformers, while also efficient, tend to be bulkier and heavier due to their larger core diameter and winding structure. Choosing between these two affects your device's overall size and portability, with ring transformers often providing a more space-saving solution.

Magnetic Field and EMI Characteristics

Ring transformers produce a uniform magnetic field that reduces electromagnetic interference (EMI) by minimizing leakage flux, enhancing performance in sensitive electronic circuits. Toroidal transformers generate low external magnetic fields due to their closed-loop core design, resulting in minimal EMI emissions and improved efficiency. Your choice between these transformers significantly impacts noise reduction and electromagnetic compatibility in precision applications.

Application Suitability

Ring transformers offer compact size and low electromagnetic interference, making them ideal for audio equipment and precision instruments where signal integrity is critical. Toroidal transformers provide higher efficiency and better thermal performance, suited for industrial power supplies, medical devices, and high-power applications requiring consistent voltage regulation. Both types excel in specific environments, with ring transformers preferred for sensitive electronics and toroidal transformers favored in demanding power and energy management scenarios.

Installation and Mounting Factors

Ring transformers feature a compact, symmetrical design that simplifies mounting in tight spaces, allowing for easy integration into various chassis configurations without special brackets. Toroidal transformers, with their doughnut-shaped core, require secure mounting plates or clamps to avoid vibration and noise issues, making installation slightly more involved but offering better electromagnetic interference performance. Your choice depends on the available mounting space and noise sensitivity requirements for optimal transformer placement.

Cost Analysis and Availability

Ring transformers typically cost less due to simpler manufacturing processes and widespread availability from multiple suppliers, making them a budget-friendly option for various electronic applications. Toroidal transformers, while generally more expensive because of their complex winding techniques and superior efficiency, may present cost advantages in long-term energy savings and reduced electromagnetic interference. Availability of ring transformers is higher in standard sizes, whereas toroidal transformers often require custom orders, potentially affecting lead times and initial costs.

Durability and Maintenance

Ring transformers offer enhanced durability due to their circular core design, which evenly distributes magnetic flux and reduces core losses, resulting in less wear over time. Toroidal transformers provide superior resistance to mechanical vibrations and electromagnetic interference, minimizing the need for frequent maintenance. Choosing the right transformer impacts your system's longevity and servicing frequency, with ring transformers typically requiring less complex upkeep compared to toroidal types.

Pros and Cons Summary

Ring transformers offer superior energy efficiency and low electromagnetic interference, making them ideal for sensitive electronic devices, yet they can be more costly and harder to source compared to toroidal transformers. Toroidal transformers provide a compact size and excellent magnetic performance with easier manufacturing, but they may generate higher levels of magnetic leakage and noise. Your choice depends on balancing the need for efficiency and noise reduction against budget and availability constraints.

Ring Transformer vs Toroidal Transformer Infographic

electrown.com

electrown.com