RTD sensors provide precise and stable temperature measurements over a wide range, ideal for applications requiring high accuracy and repeatability, while thermocouples offer faster response times and a broader temperature range, making them suitable for high-temperature or harsh environments. Explore the rest of the article to understand which sensor best fits Your specific temperature monitoring needs.

Table of Comparison

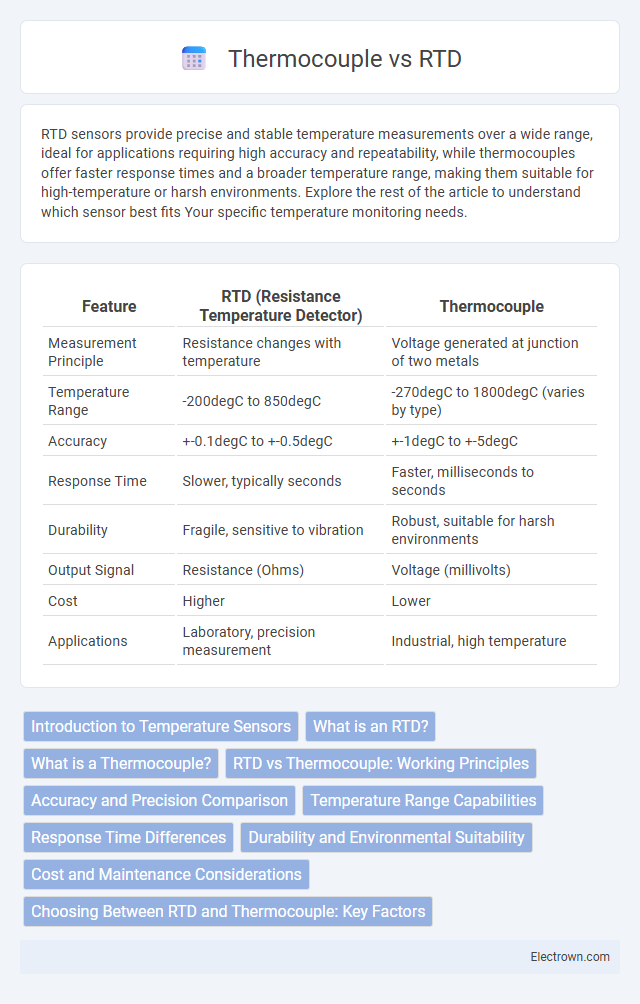

| Feature | RTD (Resistance Temperature Detector) | Thermocouple |

|---|---|---|

| Measurement Principle | Resistance changes with temperature | Voltage generated at junction of two metals |

| Temperature Range | -200degC to 850degC | -270degC to 1800degC (varies by type) |

| Accuracy | +-0.1degC to +-0.5degC | +-1degC to +-5degC |

| Response Time | Slower, typically seconds | Faster, milliseconds to seconds |

| Durability | Fragile, sensitive to vibration | Robust, suitable for harsh environments |

| Output Signal | Resistance (Ohms) | Voltage (millivolts) |

| Cost | Higher | Lower |

| Applications | Laboratory, precision measurement | Industrial, high temperature |

Introduction to Temperature Sensors

RTDs (Resistance Temperature Detectors) and thermocouples are widely used temperature sensors differing primarily in measurement principles and accuracy. RTDs utilize the predictable change in electrical resistance of metals like platinum with temperature, offering high precision and stability over a broad temperature range. Your choice depends on application requirements, with thermocouples preferred for extreme temperatures and fast response due to their voltage-based thermoelectric effect.

What is an RTD?

An RTD (Resistance Temperature Detector) measures temperature by correlating the resistance of a metal, typically platinum, with temperature changes. Known for its high accuracy and stability, an RTD provides precise temperature readings over a broad range, making it ideal for industrial applications. Unlike thermocouples, RTDs offer better repeatability and are less susceptible to electrical noise, which enhances measurement reliability.

What is a Thermocouple?

A thermocouple is a temperature sensor that measures temperature by generating a voltage based on the junction of two dissimilar metals. It offers rapid response times and can measure a wide temperature range, making it ideal for industrial applications. Your choice between a thermocouple and an RTD depends on factors like accuracy, temperature range, and environmental conditions.

RTD vs Thermocouple: Working Principles

RTDs operate based on the principle that electrical resistance in metals increases with temperature, using pure platinum elements for high accuracy and stability. Thermocouples generate a voltage due to the Seebeck effect when two dissimilar metals are joined, allowing temperature measurement from this thermoelectric voltage. RTDs provide precise and linear temperature readings but respond slower, while thermocouples excel in fast response and wide temperature range with less inherent accuracy.

Accuracy and Precision Comparison

RTDs offer higher accuracy and better long-term stability compared to thermocouples, with typical errors as low as +-0.1degC. Thermocouples provide wider temperature ranges but generally have lower precision, often around +-1 to +-2degC. The superior linearity of RTDs enhances precise measurements in applications requiring consistent temperature control.

Temperature Range Capabilities

RTDs (Resistance Temperature Detectors) typically operate effectively within a temperature range of -200degC to 850degC, offering high accuracy and stability for moderate temperature measurements. Thermocouples cover a broader temperature spectrum, from -270degC up to 2500degC depending on the type (e.g., Type K, Type S), making them suitable for extreme temperature environments. The choice between RTD and thermocouple depends largely on the required temperature range and application-specific accuracy needs.

Response Time Differences

RTDs generally exhibit slower response times compared to thermocouples due to their larger thermal mass and construction materials. Thermocouples respond rapidly to temperature changes, often within milliseconds, making them ideal for applications requiring quick detection. Your choice depends on whether fast reaction or long-term stability is more critical for precise temperature measurement.

Durability and Environmental Suitability

RTDs exhibit superior durability and stability in harsh environments due to their robust construction and resistance to oxidation, making them ideal for long-term use in controlled conditions. Thermocouples withstand extreme temperatures and rapid temperature fluctuations better, offering greater environmental versatility in high-temperature or corrosive settings. Selecting between RTD and thermocouple depends on the specific durability needs and environmental challenges of the application.

Cost and Maintenance Considerations

RTDs typically come with higher upfront costs compared to thermocouples due to their precise construction and materials like platinum. However, thermocouples generally incur lower maintenance expenses, as they are more rugged and better suited for harsh environments. Your choice between RTD and thermocouple should weigh initial investment against long-term reliability and upkeep based on application needs.

Choosing Between RTD and Thermocouple: Key Factors

Choosing between RTD and thermocouple sensors depends on factors such as temperature range, accuracy, and response time. RTDs provide higher accuracy and stability for temperatures typically up to 600degC, while thermocouples can measure extreme temperatures above 1,800degC with faster response times. Your application's environment and required precision will guide the optimal sensor selection for reliable temperature measurement.

RTD vs Thermocouple Infographic

electrown.com

electrown.com