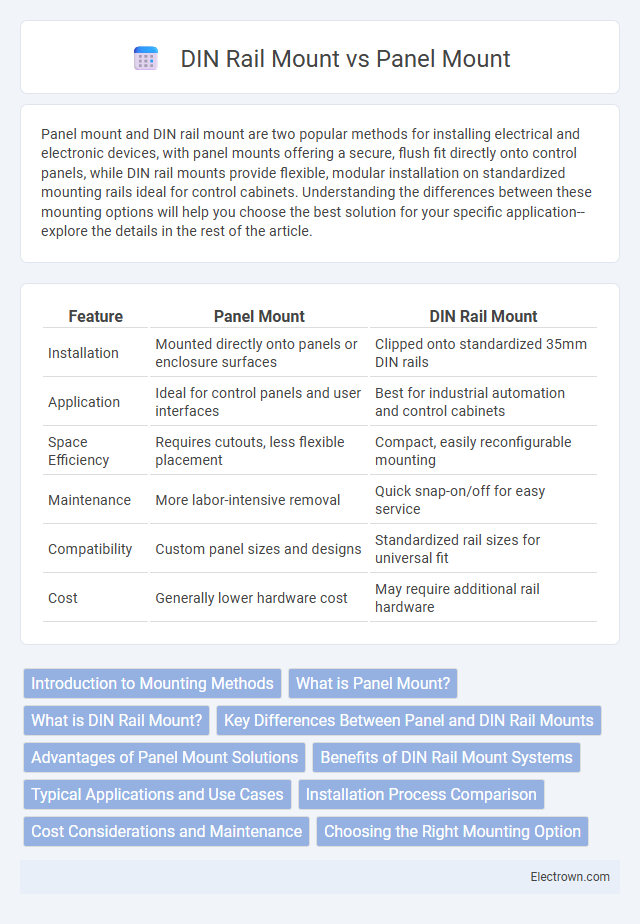

Panel mount and DIN rail mount are two popular methods for installing electrical and electronic devices, with panel mounts offering a secure, flush fit directly onto control panels, while DIN rail mounts provide flexible, modular installation on standardized mounting rails ideal for control cabinets. Understanding the differences between these mounting options will help you choose the best solution for your specific application--explore the details in the rest of the article.

Table of Comparison

| Feature | Panel Mount | DIN Rail Mount |

|---|---|---|

| Installation | Mounted directly onto panels or enclosure surfaces | Clipped onto standardized 35mm DIN rails |

| Application | Ideal for control panels and user interfaces | Best for industrial automation and control cabinets |

| Space Efficiency | Requires cutouts, less flexible placement | Compact, easily reconfigurable mounting |

| Maintenance | More labor-intensive removal | Quick snap-on/off for easy service |

| Compatibility | Custom panel sizes and designs | Standardized rail sizes for universal fit |

| Cost | Generally lower hardware cost | May require additional rail hardware |

Introduction to Mounting Methods

Panel mount and DIN rail mount are two common methods for installing electrical components in industrial and automation systems. Panel mount involves directly securing devices onto a flat panel or enclosure surface, providing a compact and clean installation ideal for operator interfaces and control panels. DIN rail mount uses a standardized metal rail to snap components into place, offering easy installation, flexibility, and scalability for modular automation setups.

What is Panel Mount?

Panel Mount refers to a type of enclosure or device installation method where components are securely fixed directly onto a pre-cut panel surface, commonly found in control panels and industrial equipment. This mounting style offers easy access for maintenance and clear visibility of indicators or controls, making it ideal for user interfaces and monitoring systems. Your choice of Panel Mount ensures streamlined integration within existing panels, providing a robust and organized setup.

What is DIN Rail Mount?

DIN Rail Mount refers to a standardized metal rail used for mounting industrial control equipment inside electrical enclosures, providing secure and organized installation of components like circuit breakers, relays, and terminal blocks. It offers easy snap-on or snap-off mounting, improving maintenance efficiency and space utilization within control panels. DIN rails comply with international standards such as IEC 60715, ensuring compatibility with various industrial devices.

Key Differences Between Panel and DIN Rail Mounts

Panel mount devices are installed directly onto flat surfaces such as control panels, providing a secure and flush fit ideal for user interfaces and display elements. DIN rail mount components are clipped onto standardized metal rails commonly found inside electrical enclosures, allowing for easy installation, removal, and modular expansion of industrial automation systems. Your choice depends on space constraints and accessibility requirements, with panel mounts suited for front-facing controls and DIN rail mounts optimized for organized internal wiring and equipment housing.

Advantages of Panel Mount Solutions

Panel mount solutions offer superior stability and security by firmly attaching devices directly to control panels, reducing vibrations and movement in industrial environments. These mounts provide easy access for maintenance and monitoring without the need for additional mounting accessories, streamlining your installation process. Their compact design saves valuable space and ensures a clean, organized setup, enhancing overall system reliability.

Benefits of DIN Rail Mount Systems

DIN rail mount systems offer superior modularity and ease of installation, enabling quick addition or removal of components without extensive reconfiguration. Their standardized metal rails provide robust mechanical support and excellent grounding capabilities, enhancing system reliability in industrial environments. Space efficiency is maximized through compact and organized layouts, simplifying maintenance and reducing wiring complexity.

Typical Applications and Use Cases

Panel mount enclosures are commonly used in control panels, instrumentation, and automation systems where compact integration and ease of access are essential. DIN rail mounts are ideal for industrial environments, offering modularity and quick installation for circuit breakers, relays, and PLCs. Your choice depends on whether you prioritize streamlined panel integration or flexible, scalable mounting solutions for diverse electrical components.

Installation Process Comparison

Panel mount installation involves securing the device directly onto a flat surface using screws or fasteners, offering a flush and stable mounting option ideal for control panels and equipment enclosures. DIN rail mount installation requires clipping the device onto a standardized metal rail, enabling quick snap-on and snap-off assembly that simplifies device replacement and system expansion in industrial settings. The panel mount method demands more precise measurements and cutouts, whereas DIN rail mounts prioritize modularity and ease of reconfiguration during installation.

Cost Considerations and Maintenance

Panel mount devices generally incur higher installation costs due to labor-intensive mounting and wiring processes, whereas DIN rail mounts offer cost-effective and faster installation with standardized frameworks. Maintenance for panel mounts can be more complex and time-consuming, as accessing components often requires panel disassembly, while DIN rail systems enable straightforward component replacement and scalability with minimal downtime. Selecting between the two depends on budget constraints and long-term maintenance efficiency for industrial automation setups.

Choosing the Right Mounting Option

Choosing the right mounting option depends on your installation environment and equipment requirements. Panel mount devices offer a clean, flush appearance ideal for control panels with limited space, ensuring easy access and secure attachment. DIN rail mounts provide flexibility and modularity, making them suitable for complex systems where quick installation and reconfiguration are essential.

Panel Mount vs DIN Rail Mount Infographic

electrown.com

electrown.com