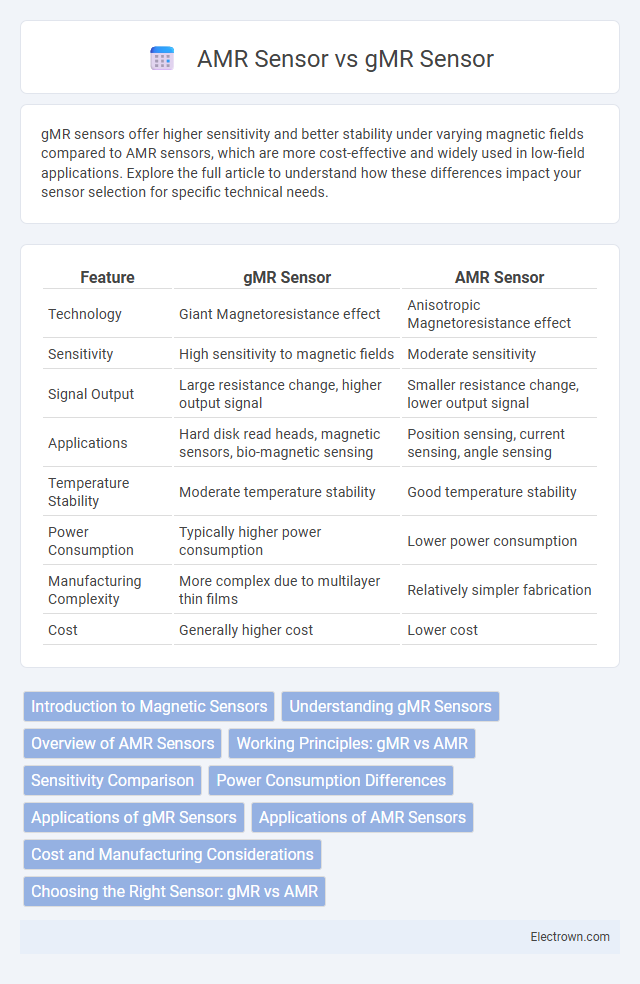

gMR sensors offer higher sensitivity and better stability under varying magnetic fields compared to AMR sensors, which are more cost-effective and widely used in low-field applications. Explore the full article to understand how these differences impact your sensor selection for specific technical needs.

Table of Comparison

| Feature | gMR Sensor | AMR Sensor |

|---|---|---|

| Technology | Giant Magnetoresistance effect | Anisotropic Magnetoresistance effect |

| Sensitivity | High sensitivity to magnetic fields | Moderate sensitivity |

| Signal Output | Large resistance change, higher output signal | Smaller resistance change, lower output signal |

| Applications | Hard disk read heads, magnetic sensors, bio-magnetic sensing | Position sensing, current sensing, angle sensing |

| Temperature Stability | Moderate temperature stability | Good temperature stability |

| Power Consumption | Typically higher power consumption | Lower power consumption |

| Manufacturing Complexity | More complex due to multilayer thin films | Relatively simpler fabrication |

| Cost | Generally higher cost | Lower cost |

Introduction to Magnetic Sensors

Magnetic sensors detect and measure magnetic fields, playing crucial roles in various applications such as automotive systems, industrial automation, and consumer electronics. The Giant Magnetoresistance (GMR) sensor offers high sensitivity and fast response by utilizing multilayer thin films, making it ideal for precise field detection. Anisotropic Magnetoresistance (AMR) sensors rely on changes in electrical resistance caused by the magnetic field direction in ferromagnetic materials, providing robust performance and cost-effectiveness for many standard magnetic sensing needs.

Understanding gMR Sensors

gMR sensors utilize giant magnetoresistance effects to detect minute changes in magnetic fields with high sensitivity and precision, making them ideal for advanced data storage and magnetic field sensing applications. These sensors outperform AMR (anisotropic magnetoresistance) sensors by offering greater signal-to-noise ratios and enhanced temperature stability, which leads to improved accuracy in measuring magnetic flux changes. The multilayer thin-film structure in gMR sensors enables them to respond efficiently to external magnetic fields, distinguishing them from the single-layer configurations found in AMR sensors.

Overview of AMR Sensors

AMR (Anisotropic Magnetoresistance) sensors detect magnetic fields by measuring changes in electrical resistance caused by the alignment of magnetic domains within a thin ferromagnetic film. They offer high sensitivity, low power consumption, and excellent temperature stability, making them ideal for applications like position sensing, current sensing, and electronic compassing. Your choice of AMR sensors ensures reliable performance in environments requiring precise magnetic field detection and robust signal output.

Working Principles: gMR vs AMR

GMR sensors operate based on the giant magnetoresistance effect, where the electrical resistance changes significantly due to spin-dependent electron scattering in multilayer thin films subjected to external magnetic fields. AMR sensors rely on the anisotropic magnetoresistance effect, where resistance varies as a function of the angle between the magnetization direction and the electric current within ferromagnetic materials. The distinct working principles influence their sensitivity, linearity, and applications, with GMR sensors typically demonstrating higher sensitivity and better miniaturization potential compared to AMR sensors.

Sensitivity Comparison

gMR sensors exhibit higher sensitivity compared to AMR sensors due to their giant magnetoresistance effect, which allows for more precise detection of small magnetic fields. AMR sensors provide reliable sensitivity for general applications but typically lag behind gMR sensors in detecting minute variations in magnetic flux. Your choice of sensor should consider the required sensitivity level, where gMR sensors excel in high-performance magnetic sensing tasks.

Power Consumption Differences

GMR sensors typically exhibit lower power consumption compared to AMR sensors due to their spintronic-based detection mechanism, which requires minimal current to detect magnetic field changes. AMR sensors rely on changes in resistance caused by magnetic fields, often necessitating higher excitation current and thus consuming more power. This difference makes GMR sensors more suitable for battery-powered and energy-sensitive applications.

Applications of gMR Sensors

gMR sensors are widely used in applications requiring high sensitivity and precision, such as automotive wheel speed detection, hard disk drive read heads, and industrial position sensing. Their ability to detect minute changes in magnetic fields makes them ideal for data storage, navigation systems, and smart factory automation. Your choice of gMR sensors supports enhanced performance in environments demanding reliable magnetic field measurement and signal accuracy.

Applications of AMR Sensors

AMR sensors, widely used in automotive applications, provide accurate magnetic field detection for wheel speed sensing, anti-lock braking systems (ABS), and electronic stability control (ESC). These sensors are also common in consumer electronics such as smartphones and hard disk drives, enhancing orientation and position detection. Your projects benefit from AMR sensors' reliability in low power consumption and high sensitivity across diverse industrial automation and robotics applications.

Cost and Manufacturing Considerations

GMR sensors generally incur higher manufacturing costs due to complex multilayer thin-film structures and precise fabrication techniques, whereas AMR sensors benefit from simpler design and mass production efficiencies, resulting in lower overall expenses. Your choice between GMR and AMR sensors may depend on budget constraints and volume requirements, as GMR sensors demand more advanced materials and cleanroom environments. Cost-effective AMR sensors are widely used in applications prioritizing affordability and ease of manufacturing without sacrificing essential magnetic sensitivity.

Choosing the Right Sensor: gMR vs AMR

gMR sensors offer higher sensitivity and better signal stability compared to AMR sensors, making them ideal for applications requiring precise magnetic field detection. AMR sensors, while less sensitive, provide robust performance with lower power consumption and cost, suitable for simpler magnetic sensing tasks. Selecting between gMR and AMR depends on the application's accuracy requirements, environmental conditions, and budget constraints.

gMR sensor vs AMR sensor Infographic

electrown.com

electrown.com