Busbar sensors provide direct, accurate measurement of current in power distribution systems by clamping around the busbar, offering high precision for steady-state and transient conditions. Rogowski coils, flexible and non-intrusive, excel in capturing high-frequency current pulses and harmonics but require signal integration for accurate readings; explore the rest of the article to determine which solution best fits your application needs.

Table of Comparison

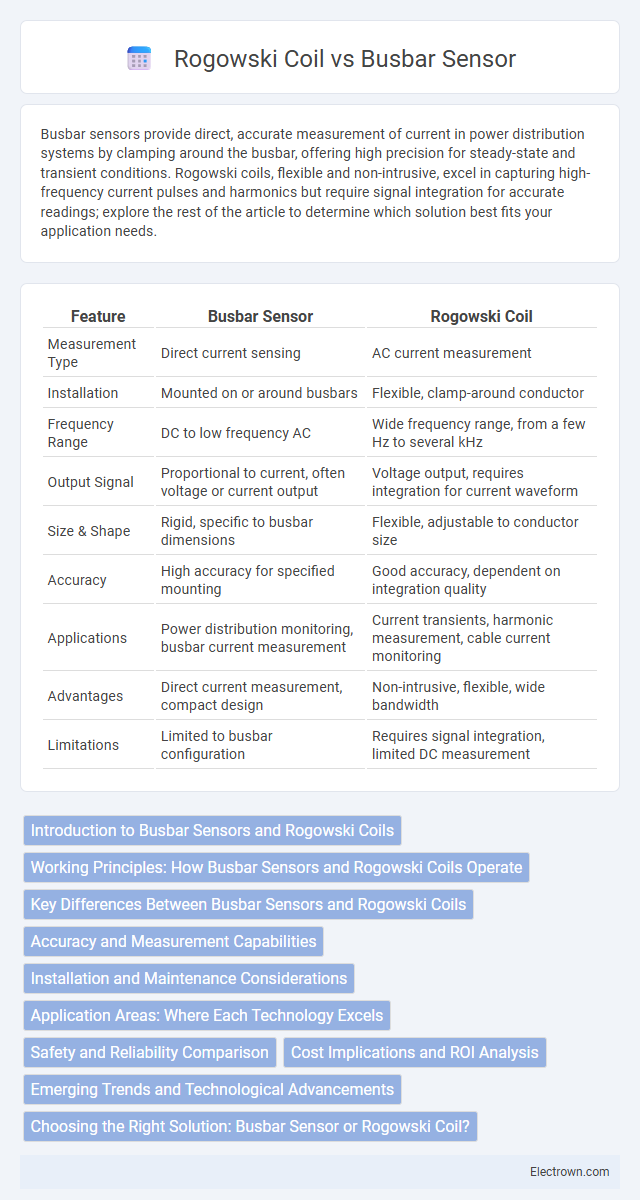

| Feature | Busbar Sensor | Rogowski Coil |

|---|---|---|

| Measurement Type | Direct current sensing | AC current measurement |

| Installation | Mounted on or around busbars | Flexible, clamp-around conductor |

| Frequency Range | DC to low frequency AC | Wide frequency range, from a few Hz to several kHz |

| Output Signal | Proportional to current, often voltage or current output | Voltage output, requires integration for current waveform |

| Size & Shape | Rigid, specific to busbar dimensions | Flexible, adjustable to conductor size |

| Accuracy | High accuracy for specified mounting | Good accuracy, dependent on integration quality |

| Applications | Power distribution monitoring, busbar current measurement | Current transients, harmonic measurement, cable current monitoring |

| Advantages | Direct current measurement, compact design | Non-intrusive, flexible, wide bandwidth |

| Limitations | Limited to busbar configuration | Requires signal integration, limited DC measurement |

Introduction to Busbar Sensors and Rogowski Coils

Busbar sensors directly measure electrical currents by clamping around busbars, offering high accuracy and seamless integration in electrical panels. Rogowski coils are flexible, non-intrusive devices that detect current by measuring magnetic fields around conductors without requiring direct contact. Your choice between busbar sensors and Rogowski coils depends on installation constraints, required accuracy, and the specific electrical monitoring application.

Working Principles: How Busbar Sensors and Rogowski Coils Operate

Busbar sensors operate by detecting magnetic fields produced by current flow through conductors, using Hall effect or fluxgate technology to provide direct measurement of current. Rogowski coils consist of a flexible, air-core coil wrapped around a conductor, generating a voltage proportional to the rate of change of current, which requires integration to obtain the actual current value. Your choice between these sensors depends on the need for direct or indirect current measurement and the specific application environment.

Key Differences Between Busbar Sensors and Rogowski Coils

Busbar sensors directly measure current through physical contact with conductive busbars, offering high accuracy and compact installation for monitoring electrical systems. Rogowski coils provide non-intrusive, flexible current measurement by encircling conductors without direct contact, ideal for transient or large current detection. Your choice depends on installation requirements, measurement accuracy, and the type of current signals to be monitored.

Accuracy and Measurement Capabilities

Busbar sensors provide high accuracy in direct current (DC) and low-frequency AC measurements due to their precise magnetic field detection around conductors. Rogowski coils excel in capturing high-frequency transient currents and waveform distortions with excellent linearity and wide bandwidth but may require complex signal processing for accurate integration. Measurement capabilities of busbar sensors are ideal for steady-state current monitoring, whereas Rogowski coils are preferred for dynamic, transient, and pulsed current analysis.

Installation and Maintenance Considerations

Busbar sensors offer straightforward installation with minimal space requirements, often integrating directly onto busbars without complex mounting hardware, reducing setup time and simplifying maintenance routines. Rogowski coils, being flexible and non-intrusive, can be easily wrapped around conductors in tight or irregular spaces, but require secure positioning and periodic calibration to maintain accuracy, which may increase maintenance efforts. Both technologies provide reliable current measurement, yet the choice depends on balancing ease of installation with long-term maintenance demands in specific electrical environments.

Application Areas: Where Each Technology Excels

Busbar sensors excel in low to medium voltage applications, providing precise current measurements in switchgear, transformers, and power distribution units, especially in industrial environments. Rogowski coils are ideal for high-current and transient fault detection in power generation, transmission lines, and renewable energy systems due to their lightweight, flexible design and wide frequency response. Each technology optimizes current monitoring performance based on installation flexibility and operating current ranges.

Safety and Reliability Comparison

Busbar sensors offer high safety by directly measuring current without needing to break the circuit, minimizing electrical hazards and ensuring continuous system monitoring. Rogowski coils provide enhanced reliability through their non-intrusive design, immunity to saturation, and ability to measure high-frequency transient currents with precision. Your choice depends on whether you prioritize direct contact accuracy or flexible, safe installation in complex electrical systems.

Cost Implications and ROI Analysis

Busbar sensors generally offer lower upfront costs compared to Rogowski coils, making them a budget-friendly choice for basic current measurement applications. Rogowski coils, although more expensive initially, provide greater flexibility and accuracy in monitoring complex or high-frequency currents, leading to enhanced system performance and reduced downtime. Your ROI improves with Rogowski coils when precision and adaptability reduce maintenance costs and energy losses over time.

Emerging Trends and Technological Advancements

Emerging trends in busbar sensor technology emphasize compact designs and integrated fault detection systems that enhance energy efficiency and reliability in power distribution. Rogowski coils continue to advance with improved sensitivity and digital signal processing, enabling precise real-time current monitoring in high-frequency applications and fault diagnostics. Your choice between these technologies depends on the specific application requirements, including space constraints and the need for non-intrusive current measurement.

Choosing the Right Solution: Busbar Sensor or Rogowski Coil?

Busbar sensors provide direct contact measurement with high accuracy for fixed installations, making them ideal for compact switchgear environments and precise current monitoring. Rogowski coils offer flexible, non-intrusive current measurement suitable for large conductors and varying current ranges, excelling in temporary or retrofit applications with easy installation. Consider your system's physical constraints and required measurement precision to determine whether a busbar sensor's direct sensing or a Rogowski coil's flexibility best fits your application.

busbar sensor vs Rogowski coil Infographic

electrown.com

electrown.com