Magnetic contactors offer reliable mechanical switching for high-power applications, while solid state relays provide silent, fast switching with no moving parts, making them ideal for low-maintenance systems. Discover which option best suits Your specific needs by reading the rest of the article.

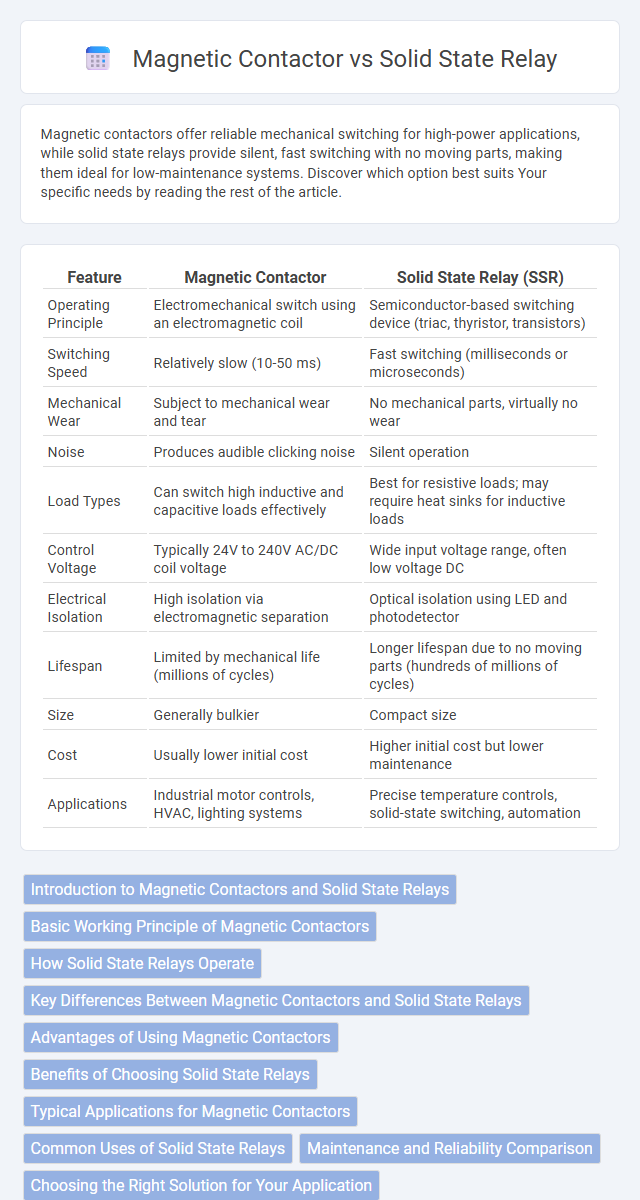

Table of Comparison

| Feature | Magnetic Contactor | Solid State Relay (SSR) |

|---|---|---|

| Operating Principle | Electromechanical switch using an electromagnetic coil | Semiconductor-based switching device (triac, thyristor, transistors) |

| Switching Speed | Relatively slow (10-50 ms) | Fast switching (milliseconds or microseconds) |

| Mechanical Wear | Subject to mechanical wear and tear | No mechanical parts, virtually no wear |

| Noise | Produces audible clicking noise | Silent operation |

| Load Types | Can switch high inductive and capacitive loads effectively | Best for resistive loads; may require heat sinks for inductive loads |

| Control Voltage | Typically 24V to 240V AC/DC coil voltage | Wide input voltage range, often low voltage DC |

| Electrical Isolation | High isolation via electromagnetic separation | Optical isolation using LED and photodetector |

| Lifespan | Limited by mechanical life (millions of cycles) | Longer lifespan due to no moving parts (hundreds of millions of cycles) |

| Size | Generally bulkier | Compact size |

| Cost | Usually lower initial cost | Higher initial cost but lower maintenance |

| Applications | Industrial motor controls, HVAC, lighting systems | Precise temperature controls, solid-state switching, automation |

Introduction to Magnetic Contactors and Solid State Relays

Magnetic contactors are electromechanical devices designed for switching high-power electrical loads by using an electromagnetic coil to close or open contacts, making them ideal for controlling motors and lighting systems. Solid state relays (SSRs) operate without moving parts, using semiconductor components like thyristors or triacs to achieve fast, silent switching with higher reliability and longer lifespan in low to medium power applications. The choice between magnetic contactors and SSRs depends on factors such as load type, switching speed, electrical noise tolerance, and maintenance requirements.

Basic Working Principle of Magnetic Contactors

Magnetic contactors operate by using an electromagnetic coil to create a magnetic field that attracts a movable iron core, closing the contact points and allowing current to flow through the circuit. These devices rely on mechanical movement for switching, making them suitable for high current applications but subject to wear over time. In contrast, solid state relays use semiconductor devices for switching without moving parts, providing faster, quieter operation and longer lifespan.

How Solid State Relays Operate

Solid state relays operate by using semiconductor devices such as thyristors, triacs, or transistors to switch electrical loads without moving parts, ensuring silent and fast switching. Unlike magnetic contactors, which rely on electromagnetic coils to physically close contacts, solid state relays provide superior durability and reliability in high-frequency switching applications. Your choice between these devices depends on factors like switching speed, electrical noise tolerance, and maintenance requirements.

Key Differences Between Magnetic Contactors and Solid State Relays

Magnetic contactors use electromagnetic coils to physically open and close electrical contacts, providing reliable switching for high-current applications, while solid state relays (SSRs) utilize semiconductor components for rapid, silent switching without mechanical wear. SSRs offer advantages in terms of faster switching speeds, longer lifespan, and reduced maintenance due to the lack of moving parts, whereas magnetic contactors excel in handling high inrush currents and robust load conditions. Your choice depends on the application requirements, with SSRs suited for precise control and quieter operation, and magnetic contactors preferred for heavy-duty industrial environments.

Advantages of Using Magnetic Contactors

Magnetic contactors offer reliable mechanical switching for high-current applications, ensuring durability and easy maintenance in industrial automation systems. They provide superior overload protection and clear physical separation of contacts, reducing electrical noise and enhancing system safety. Your equipment benefits from the robust construction and straightforward troubleshooting that magnetic contactors provide compared to solid state relays.

Benefits of Choosing Solid State Relays

Solid state relays offer superior durability and reliability due to the absence of mechanical parts, resulting in longer operational life and reduced maintenance costs compared to magnetic contactors. Their fast switching speeds and silent operation enhance performance in applications requiring frequent or rapid switching. Solid state relays also provide better resistance to vibration, shock, and electrical noise, making them ideal for harsh industrial environments.

Typical Applications for Magnetic Contactors

Magnetic contactors are commonly used in industrial automation for switching heavy electrical loads such as motors, lighting systems, and heating equipment due to their ability to handle high current and voltage. They are ideal for applications requiring frequent switching and reliable operation in harsh environments, including HVAC systems, conveyor belts, and industrial machinery. Magnetic contactors excel in scenarios that demand mechanical durability and electrical isolation, where solid state relays might be limited by heat dissipation and voltage constraints.

Common Uses of Solid State Relays

Solid state relays (SSRs) are commonly used in applications requiring silent operation and fast switching, such as in industrial automation, HVAC systems, and conveyor controls. Unlike magnetic contactors, SSRs excel in environments with frequent on/off cycles and sensitive electronic control systems due to their lack of mechanical parts. Their ability to handle low-current signals and provide electrical isolation makes them ideal for temperature control, lighting systems, and semiconductor manufacturing equipment.

Maintenance and Reliability Comparison

Magnetic contactors require routine maintenance due to mechanical wear, such as contact pitting and coil degradation, which can lead to operational failures over time. Solid state relays (SSRs) offer higher reliability with no moving parts, resulting in minimal wear and significantly reduced maintenance needs. SSRs are ideal for applications demanding long-term stability and uninterrupted operation, especially in environments with frequent switching cycles.

Choosing the Right Solution for Your Application

Magnetic contactors offer reliable mechanical switching for high power loads and are well-suited for applications requiring clear on/off states and durability under heavy electrical stress. Solid state relays provide faster switching times, silent operation, and enhanced longevity without mechanical wear, ideal for high-frequency switching and sensitive electronic circuits. Your choice depends on factors such as load type, switching frequency, noise tolerance, and overall system reliability requirements.

Magnetic contactor vs Solid state relay Infographic

electrown.com

electrown.com