Zener barriers and galvanic isolators both protect electrical systems from lightning and surge damage, with Zener barriers diverting voltage spikes to the ground using a Zener diode and galvanic isolators preventing DC currents from passing while allowing AC signals. Understanding how each device works is crucial for enhancing the safety of your electrical setup--read on to explore their differences and applications.

Table of Comparison

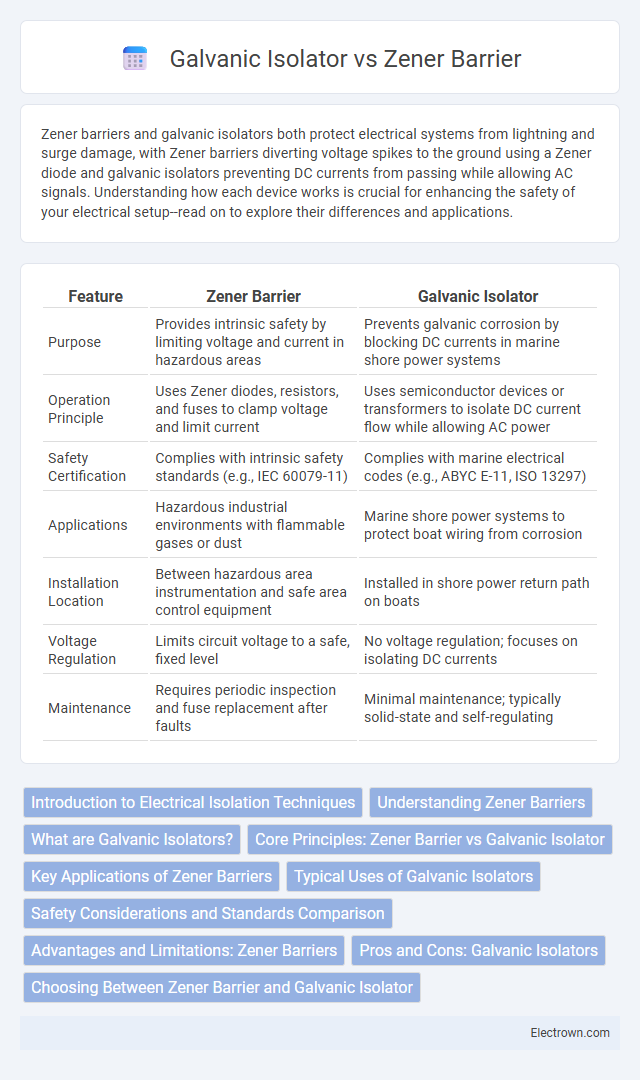

| Feature | Zener Barrier | Galvanic Isolator |

|---|---|---|

| Purpose | Provides intrinsic safety by limiting voltage and current in hazardous areas | Prevents galvanic corrosion by blocking DC currents in marine shore power systems |

| Operation Principle | Uses Zener diodes, resistors, and fuses to clamp voltage and limit current | Uses semiconductor devices or transformers to isolate DC current flow while allowing AC power |

| Safety Certification | Complies with intrinsic safety standards (e.g., IEC 60079-11) | Complies with marine electrical codes (e.g., ABYC E-11, ISO 13297) |

| Applications | Hazardous industrial environments with flammable gases or dust | Marine shore power systems to protect boat wiring from corrosion |

| Installation Location | Between hazardous area instrumentation and safe area control equipment | Installed in shore power return path on boats |

| Voltage Regulation | Limits circuit voltage to a safe, fixed level | No voltage regulation; focuses on isolating DC currents |

| Maintenance | Requires periodic inspection and fuse replacement after faults | Minimal maintenance; typically solid-state and self-regulating |

Introduction to Electrical Isolation Techniques

Zener barriers and galvanic isolators both provide essential electrical isolation techniques used in hazardous environments to prevent ignition risks. Zener barriers limit voltage and current through resistors and Zener diodes, ensuring intrinsic safety by clamping excess voltage, while galvanic isolators use transformer coupling to eliminate direct electrical connections, providing complete galvanic separation. Your choice depends on the specific application requirements for safety, signal integrity, and installation complexity in explosive atmospheres.

Understanding Zener Barriers

Zener barriers provide intrinsic safety by limiting voltage and current through a Zener diode and resistor combination, preventing sparks in hazardous environments. Unlike galvanic isolators that offer electrical isolation by physically separating circuits, Zener barriers ensure circuits remain connected to the earth grounding system for safety. Understanding Zener barriers involves recognizing their role in explosion-proof electrical systems, where strict control of energy levels is critical for preventing ignition.

What are Galvanic Isolators?

Galvanic isolators are electrical devices designed to prevent galvanic corrosion by blocking low voltage DC current while allowing AC current to pass through in marine and electrical systems. They work by isolating the boat's metal parts from stray DC currents that cause corrosion, protecting your vessel's underwater metals without disrupting the shore power supply. Unlike Zener barriers, which provide explosion protection by limiting voltage and current in hazardous areas, galvanic isolators specifically target corrosion prevention in marine environments.

Core Principles: Zener Barrier vs Galvanic Isolator

Zener barriers use voltage clamping and current limiting to protect circuits in hazardous areas by safely diverting excess voltage to ground, ensuring intrinsic safety through energy limitation. Galvanic isolators provide electrical isolation by using transformers or optocouplers to prevent direct current flow between circuits, eliminating galvanic current paths and enhancing noise immunity. Both devices serve to protect equipment but differ fundamentally in operation: Zener barriers maintain a controlled reference to earth, while galvanic isolators achieve isolation without direct grounding.

Key Applications of Zener Barriers

Zener barriers are primarily used in hazardous environments such as oil refineries, chemical plants, and mining sites to provide intrinsic safety by limiting voltage and current to prevent ignition of explosive gases. They are crucial in applications involving intrinsically safe instrumentation and control circuits in Zone 0, 1, and 2 locations. Unlike galvanic isolators, which prevent galvanic corrosion in marine electrical systems, Zener barriers enforce safety standards in industrial automation and process control systems requiring explosion-proof protection.

Typical Uses of Galvanic Isolators

Galvanic isolators are commonly used in marine electrical systems to prevent galvanic corrosion by blocking low voltage DC current while allowing the normal operation of AC shore power. They are essential for protecting boat hulls and underwater metal fittings from electrochemical damage caused by stray currents. Typical applications include sailboats, yachts, and other vessels connected to shore power grids where metal-to-metal contact with water poses corrosion risks.

Safety Considerations and Standards Comparison

Zener barriers use intrinsic safety principles, limiting voltage and current to prevent sparks in hazardous areas, complying with IEC 60079-11 standards, while galvanic isolators provide electrical isolation without energy limitation, meeting standards such as IEC 60950 for data and signal integrity. You should choose Zener barriers for explosion-proof environments requiring certified spark prevention, whereas galvanic isolators suit applications needing signal isolation without intrinsic safety constraints. Both devices enhance system safety but differ fundamentally in protection mechanisms and applicable industry standards.

Advantages and Limitations: Zener Barriers

Zener barriers offer reliable intrinsic safety by clamping voltage to a safe level during fault conditions, protecting explosive environments from sparks or ignition sources. They are simple, cost-effective, and require minimal maintenance but are limited by voltage drop and potential energy dissipation, which can affect signal integrity in sensitive instrumentation. Your choice of a Zener barrier should consider its proven durability in hazardous areas versus the lower power loss and enhanced isolation provided by galvanic isolators.

Pros and Cons: Galvanic Isolators

Galvanic isolators prevent galvanic corrosion by blocking low-voltage DC currents between your boat and shore power, offering effective corrosion control without interrupting AC power flow. They require minimal maintenance, are easy to install, and do not degrade with age, but may fail silently, necessitating periodic testing. Despite higher initial cost than Zener barriers, galvanic isolators provide reliable, seamless protection within marine electrical systems, ideal for protecting your vessel's metal components.

Choosing Between Zener Barrier and Galvanic Isolator

Choosing between a Zener barrier and a galvanic isolator depends on your application's safety requirements and electrical characteristics. Zener barriers offer reliable intrinsic safety by clamping voltage and providing a fail-safe ground, ideal for hazardous environments demanding strict explosion protection. Galvanic isolators provide complete electrical isolation without grounding, suitable for preventing ground loops and interference in sensitive measurement systems.

Zener barrier vs galvanic isolator Infographic

electrown.com

electrown.com