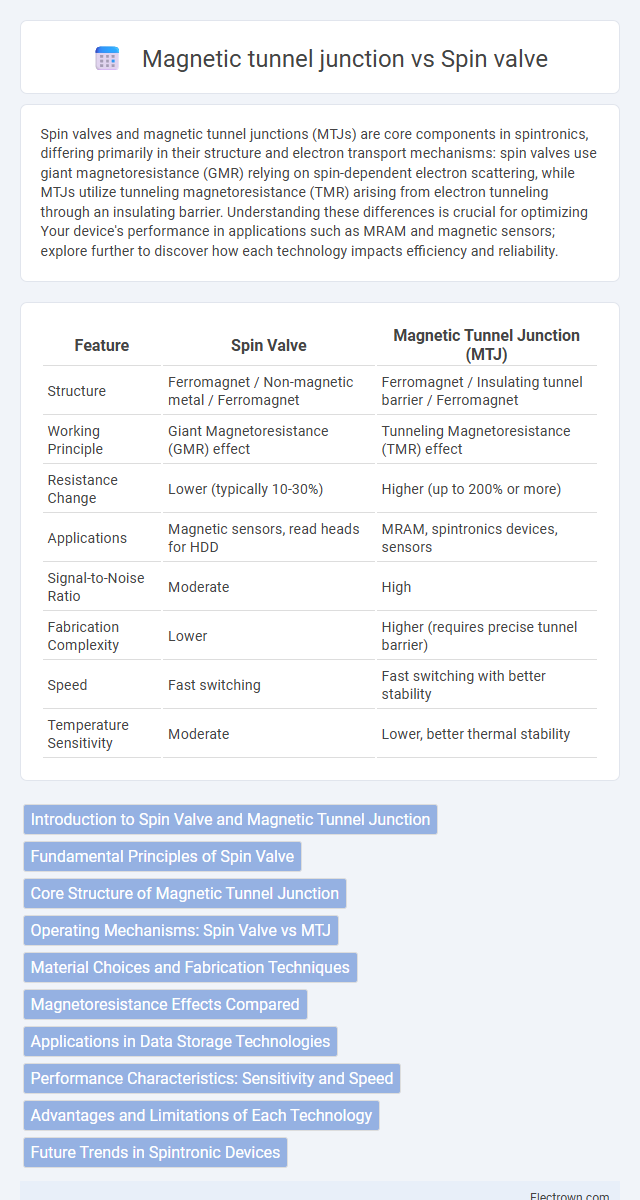

Spin valves and magnetic tunnel junctions (MTJs) are core components in spintronics, differing primarily in their structure and electron transport mechanisms: spin valves use giant magnetoresistance (GMR) relying on spin-dependent electron scattering, while MTJs utilize tunneling magnetoresistance (TMR) arising from electron tunneling through an insulating barrier. Understanding these differences is crucial for optimizing Your device's performance in applications such as MRAM and magnetic sensors; explore further to discover how each technology impacts efficiency and reliability.

Table of Comparison

| Feature | Spin Valve | Magnetic Tunnel Junction (MTJ) |

|---|---|---|

| Structure | Ferromagnet / Non-magnetic metal / Ferromagnet | Ferromagnet / Insulating tunnel barrier / Ferromagnet |

| Working Principle | Giant Magnetoresistance (GMR) effect | Tunneling Magnetoresistance (TMR) effect |

| Resistance Change | Lower (typically 10-30%) | Higher (up to 200% or more) |

| Applications | Magnetic sensors, read heads for HDD | MRAM, spintronics devices, sensors |

| Signal-to-Noise Ratio | Moderate | High |

| Fabrication Complexity | Lower | Higher (requires precise tunnel barrier) |

| Speed | Fast switching | Fast switching with better stability |

| Temperature Sensitivity | Moderate | Lower, better thermal stability |

Introduction to Spin Valve and Magnetic Tunnel Junction

Spin valves are magnetic sensors that utilize giant magnetoresistance (GMR) by alternating ferromagnetic and non-magnetic conductive layers to detect changes in magnetic fields. Magnetic tunnel junctions (MTJs) consist of two ferromagnetic layers separated by a thin insulating barrier, enabling tunneling magnetoresistance (TMR) for higher sensitivity and efficiency in data storage applications. Understanding the differences between spin valves and MTJs helps optimize your choice for various spintronic devices and memory technologies.

Fundamental Principles of Spin Valve

Spin valves operate based on giant magnetoresistance (GMR), utilizing alternating ferromagnetic and non-magnetic conductive layers to control electron spin-dependent resistance. The resistance changes as the relative alignment of magnetization between layers switches from parallel to antiparallel, enabling spintronic applications in hard drive read heads and magnetic sensors. The spin valve's fundamental principle relies on spin-polarized electron scattering modulation within layered structures, distinct from the tunneling magnetoresistance in magnetic tunnel junctions.

Core Structure of Magnetic Tunnel Junction

The core structure of a Magnetic Tunnel Junction (MTJ) consists of two ferromagnetic layers separated by a thin insulating barrier, typically magnesium oxide (MgO), allowing electron tunneling based on spin orientation. Unlike spin valves that rely on giant magnetoresistance (GMR) effects with metallic spacers, MTJs utilize tunneling magnetoresistance (TMR) to achieve higher sensitivity and faster switching speeds. Understanding this key difference in core structure helps optimize Your device design for applications in MRAM and spintronic sensors.

Operating Mechanisms: Spin Valve vs MTJ

Spin valves operate based on the giant magnetoresistance (GMR) effect, where electron spin alignment in ferromagnetic layers separated by a nonmagnetic metal spacer changes electrical resistance. Magnetic tunnel junctions (MTJs) utilize the tunneling magnetoresistance (TMR) effect, involving electron spin-dependent quantum tunneling through a thin insulating barrier between ferromagnetic layers. The difference in resistance states in spin valves and MTJs is governed by the relative magnetization orientation of the ferromagnetic layers, but MTJs generally provide higher magnetoresistance ratios due to coherent spin-dependent tunneling.

Material Choices and Fabrication Techniques

Spin valves typically utilize alternating ferromagnetic and non-magnetic metal layers such as cobalt, nickel-iron, and copper, fabricated through sputtering and molecular beam epitaxy techniques to achieve precise layer thickness and interface quality. Magnetic tunnel junctions (MTJs) employ ferromagnetic electrodes, often cobalt-iron-boron alloys, separated by an ultra-thin insulating barrier commonly made of magnesium oxide (MgO), fabricated using advanced sputtering and atomic layer deposition to create high-quality tunnel barriers essential for tunneling magnetoresistance. Your choice between these devices depends on the required magnetoresistive properties and fabrication scalability within your application.

Magnetoresistance Effects Compared

Spin valves exhibit giant magnetoresistance (GMR), where resistance changes due to spin-dependent electron scattering in multilayered ferromagnetic structures, typically offering moderate magnetoresistance ratios up to 10-15%. Magnetic tunnel junctions (MTJs) leverage tunneling magnetoresistance (TMR), featuring a thin insulating barrier between ferromagnetic layers, which enables significantly higher magnetoresistance ratios often exceeding 100% at room temperature. Your choice between spin valves and MTJs depends on the required sensitivity and application, with MTJs preferred for high-performance memory and sensor technologies due to their superior magnetoresistance effects.

Applications in Data Storage Technologies

Spin valves are widely used in hard disk drive read heads due to their ability to detect changes in magnetic fields with high sensitivity, enhancing data read accuracy. Magnetic tunnel junctions (MTJs) play a critical role in magnetic random-access memory (MRAM) by enabling non-volatile storage with fast switching speeds and high endurance. Both technologies contribute to advancing data storage solutions by improving density, speed, and energy efficiency in modern memory and recording devices.

Performance Characteristics: Sensitivity and Speed

Spin valves exhibit high sensitivity due to their reliance on giant magnetoresistance (GMR) effects, allowing precise detection of magnetic field changes with relatively fast response times. Magnetic tunnel junctions (MTJs) surpass spin valves in sensitivity by leveraging tunneling magnetoresistance (TMR), which provides larger signal output and improved noise margins, enhancing accuracy in sensing applications. Your choice between spin valves and MTJs should consider that MTJs generally offer faster switching speeds and higher sensitivity, making them more suitable for high-performance memory and sensor devices.

Advantages and Limitations of Each Technology

Spin valves offer high sensitivity and fast response times, making them ideal for magnetic field sensing in hard drives and read heads, but they suffer from moderate magnetoresistance ratios and limited thermal stability. Magnetic tunnel junctions (MTJs) provide significantly higher tunnel magnetoresistance (TMR) ratios, enabling greater signal output and enhanced data storage density in MRAM devices, although they face challenges such as higher resistance-area products and increased fabrication complexity. The choice between spin valves and MTJs depends on application-specific requirements, balancing performance factors like sensitivity, scalability, and energy efficiency.

Future Trends in Spintronic Devices

Future trends in spintronic devices emphasize advancements in magnetic tunnel junctions (MTJs) due to their higher magnetoresistance ratios and improved scalability compared to spin valves. Innovations in materials such as perpendicular magnetic anisotropy (PMA) layers and voltage-controlled magnetic anisotropy are driving enhanced energy efficiency and switching speeds in MTJ-based memories and logic devices. Your integration of these emerging MTJ technologies promises significant breakthroughs in non-volatile memory, neuromorphic computing, and quantum information systems.

Spin valve vs Magnetic tunnel junction Infographic

electrown.com

electrown.com