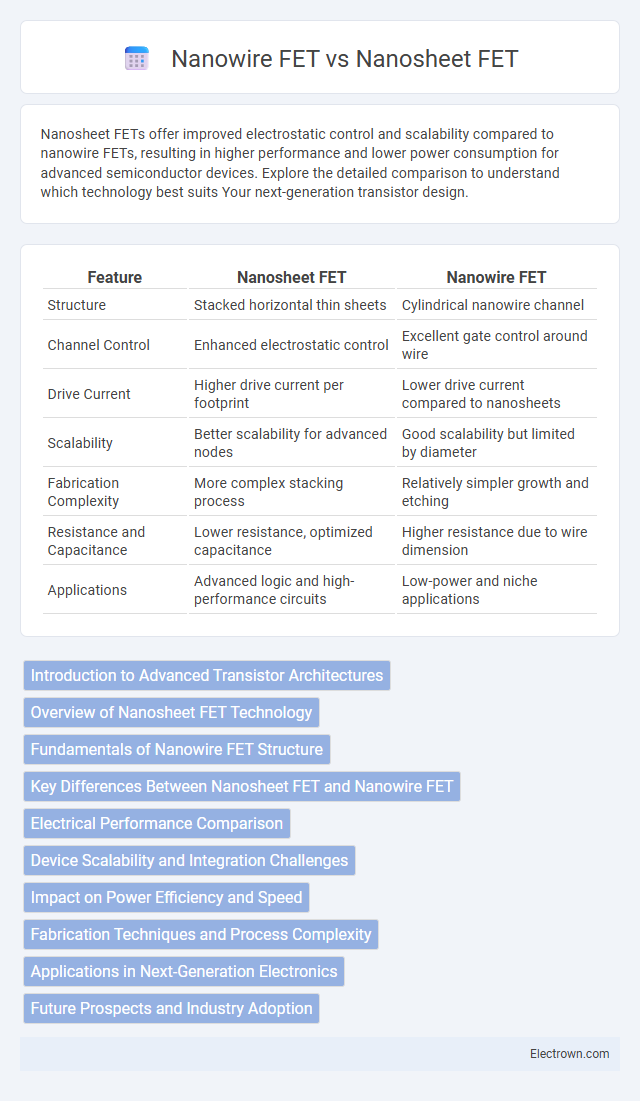

Nanosheet FETs offer improved electrostatic control and scalability compared to nanowire FETs, resulting in higher performance and lower power consumption for advanced semiconductor devices. Explore the detailed comparison to understand which technology best suits Your next-generation transistor design.

Table of Comparison

| Feature | Nanosheet FET | Nanowire FET |

|---|---|---|

| Structure | Stacked horizontal thin sheets | Cylindrical nanowire channel |

| Channel Control | Enhanced electrostatic control | Excellent gate control around wire |

| Drive Current | Higher drive current per footprint | Lower drive current compared to nanosheets |

| Scalability | Better scalability for advanced nodes | Good scalability but limited by diameter |

| Fabrication Complexity | More complex stacking process | Relatively simpler growth and etching |

| Resistance and Capacitance | Lower resistance, optimized capacitance | Higher resistance due to wire dimension |

| Applications | Advanced logic and high-performance circuits | Low-power and niche applications |

Introduction to Advanced Transistor Architectures

Nanosheet FETs and Nanowire FETs represent advanced transistor architectures designed to overcome scaling limitations in semiconductor technology by providing enhanced gate control and reduced short-channel effects. Nanosheet FETs utilize wider, planar channels that can be stacked vertically for improved drive current and efficient electrostatic control, while Nanowire FETs feature cylindrical channels offering superior gate wrap-around but face challenges in scalability and manufacturing complexity. Your choice between these architectures impacts device performance, power efficiency, and integration density in next-generation integrated circuits.

Overview of Nanosheet FET Technology

Nanosheet FET technology utilizes multiple stacked horizontal nanosheets as the channel, enabling superior electrostatic control and scalability compared to nanowire FETs, which employ cylindrical nanowires. The wider and rectangular cross-section of nanosheets allows for higher drive current and improved short-channel effects suppression. This advanced architecture supports enhanced device performance in sub-5 nm technology nodes and offers greater manufacturing flexibility for future CMOS scaling.

Fundamentals of Nanowire FET Structure

Nanowire FETs feature a one-dimensional semiconductor channel surrounded by a gate electrode, enabling enhanced electrostatic control and reduced short-channel effects. Their cylindrical geometry allows for improved carrier mobility and better gate modulation compared to planar devices. The fundamental structure consists of a nanometer-scale wire acting as the channel, encased by a gate dielectric and gate metal, optimizing the transistor's switching performance at nanoscale dimensions.

Key Differences Between Nanosheet FET and Nanowire FET

Nanosheet FETs feature wide, planar channels that enable improved electrostatic control and higher drive current compared to the cylindrical channels of Nanowire FETs, which offer superior gate control due to their fully surrounded gate architecture. The fabrication complexity of Nanosheet FETs is generally higher, but they provide better scalability for advanced technology nodes. Nanowire FETs exhibit excellent short-channel control but may suffer from lower on-state current and increased variability in manufacturing processes.

Electrical Performance Comparison

Nanosheet FETs exhibit superior electrostatic control and reduced short-channel effects compared to nanowire FETs due to their larger effective channel width and gate-all-around structure. Enhanced ON-state current (Ion) and improved subthreshold slope metrics in nanosheet FETs result from their increased channel modulation and higher drive current capabilities. Nanowire FETs, while offering excellent gate control, typically suffer from lower current densities and higher variability due to their smaller cross-sectional area and more pronounced quantum confinement effects.

Device Scalability and Integration Challenges

Nanosheet FETs offer superior device scalability compared to nanowire FETs due to their planar architecture, enabling better electrostatic control and reduced short-channel effects at sub-5nm nodes. Integration challenges for nanosheet FETs include complex layer stacking and precise thickness control, which complicate fabrication processes relative to the inherently simpler but less scalable cylindrical geometry of nanowire FETs. While nanowire FETs benefit from easier gate-all-around structures, their limited scalability and variability issues pose significant hurdles for high-density integration in advanced technology nodes.

Impact on Power Efficiency and Speed

Nanosheet FETs exhibit superior power efficiency and speed compared to Nanowire FETs due to their enhanced electrostatic control and larger effective channel width, which reduces short-channel effects and leakage currents. The planar geometry of nanosheets allows for higher drive currents at lower voltages, significantly improving switching speed and reducing power consumption in advanced semiconductor nodes. Consequently, nanosheet FETs are favored in high-performance computing applications where energy efficiency and operational speed are critical.

Fabrication Techniques and Process Complexity

Nanosheet FETs are fabricated using advanced top-down techniques such as selective etching and layer stacking, which allow precise control over channel dimensions but require complex lithography and multiple patterning steps. Nanowire FETs typically use bottom-up approaches like vapor-liquid-solid (VLS) growth or top-down etching, often simplifying fabrication but posing challenges in uniformity and alignment. Your choice between nanosheet and nanowire FET fabrication depends on the trade-off between process complexity and dimensional control critical for device performance.

Applications in Next-Generation Electronics

Nanosheet FETs offer enhanced electrostatic control and scalability, making them ideal for high-performance logic devices and advanced computing applications in next-generation electronics. Nanowire FETs provide superior gate control and are well-suited for low-power and flexible electronics, enabling efficient operation in wearable and IoT devices. Your choice between these technologies depends on the specific requirements for power efficiency, performance, and device architecture in emerging electronic systems.

Future Prospects and Industry Adoption

Nanosheet FETs offer enhanced electrostatic control and scalability, making them a favorable choice for sub-3nm technology nodes in advanced semiconductor manufacturing. Nanowire FETs provide superior gate control with a cylindrical geometry but face challenges in uniformity and mass production cost. The semiconductor industry trends towards nanosheet FET adoption due to better integration with existing fabrication processes and improved performance metrics for next-generation logic and memory applications.

Nanosheet FET vs Nanowire FET Infographic

electrown.com

electrown.com