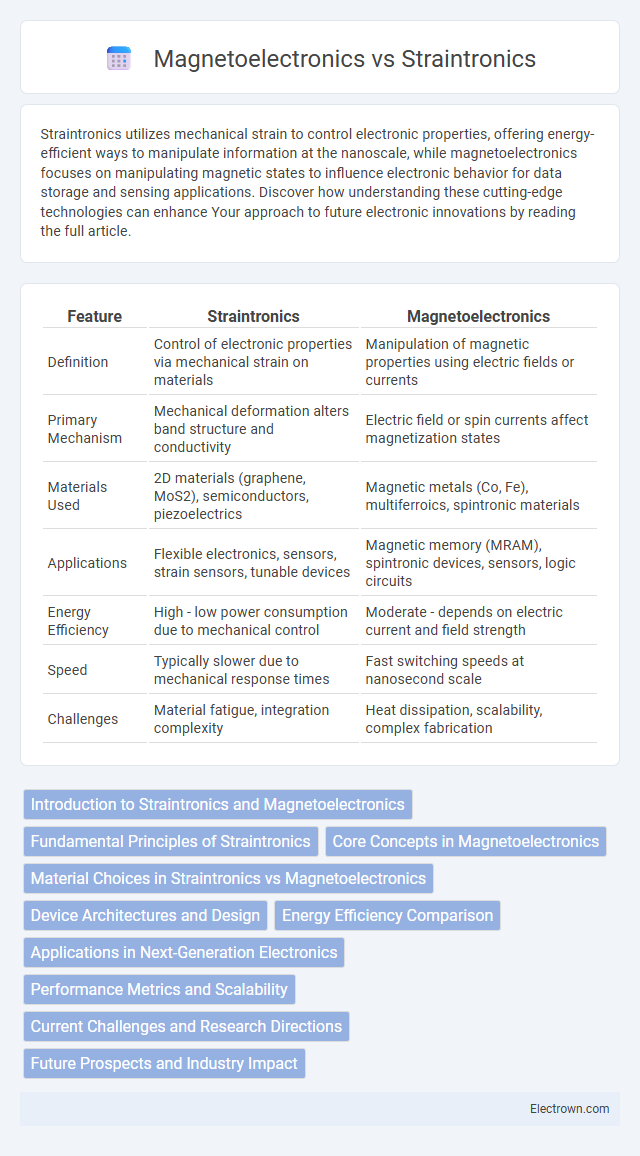

Straintronics utilizes mechanical strain to control electronic properties, offering energy-efficient ways to manipulate information at the nanoscale, while magnetoelectronics focuses on manipulating magnetic states to influence electronic behavior for data storage and sensing applications. Discover how understanding these cutting-edge technologies can enhance Your approach to future electronic innovations by reading the full article.

Table of Comparison

| Feature | Straintronics | Magnetoelectronics |

|---|---|---|

| Definition | Control of electronic properties via mechanical strain on materials | Manipulation of magnetic properties using electric fields or currents |

| Primary Mechanism | Mechanical deformation alters band structure and conductivity | Electric field or spin currents affect magnetization states |

| Materials Used | 2D materials (graphene, MoS2), semiconductors, piezoelectrics | Magnetic metals (Co, Fe), multiferroics, spintronic materials |

| Applications | Flexible electronics, sensors, strain sensors, tunable devices | Magnetic memory (MRAM), spintronic devices, sensors, logic circuits |

| Energy Efficiency | High - low power consumption due to mechanical control | Moderate - depends on electric current and field strength |

| Speed | Typically slower due to mechanical response times | Fast switching speeds at nanosecond scale |

| Challenges | Material fatigue, integration complexity | Heat dissipation, scalability, complex fabrication |

Introduction to Straintronics and Magnetoelectronics

Straintronics exploits mechanical strain to control electronic properties in materials, offering low-energy data storage and logic devices by manipulating electron spin through strain-induced effects. Magnetoelectronics, or spintronics, utilizes electron spin and magnetic fields to enhance device performance, enabling faster and more efficient information processing with magnetic materials. Your understanding of these fields highlights the integration of mechanical and magnetic control mechanisms in next-generation electronics.

Fundamental Principles of Straintronics

Straintronics leverages mechanical strain to control electronic properties in materials, enabling low-energy operation by manipulating lattice structures and electron spin without electric current. This contrasts with magnetoelectronics, which relies on magnetic fields or spin currents to influence magnetization states for data storage or logic devices. Understanding the fundamental principles of straintronics allows you to explore novel approaches in energy-efficient spintronic applications and nanoscale device engineering.

Core Concepts in Magnetoelectronics

Magnetoelectronics centers on the interplay between magnetic fields and electronic charge carriers, exploiting electron spin alongside charge for enhanced device functionalities. Core concepts include spintronics, where spin polarization and spin transfer torque enable advanced data storage and magnetic sensors, surpassing traditional electronics in speed and efficiency. You can harness magnetoelectronic principles to innovate in memory devices, spin valves, and magnetic tunnel junctions, driving next-generation technology advancements.

Material Choices in Straintronics vs Magnetoelectronics

Straintronics primarily utilizes piezoelectric materials such as lead zirconate titanate (PZT) and ferroelectric polymers to induce mechanical strain for controlling electronic properties, while magnetoelectronics relies on ferromagnetic materials like cobalt, nickel, and iron alloys to manipulate spin states through magnetic fields. In straintronics, material flexibility and efficient strain transfer are crucial for device performance, whereas magnetoelectronics demands materials with high magnetic anisotropy and spin polarization to optimize spintronic functions. Your choice of materials directly impacts the energy efficiency and operational speeds of devices in these two emerging fields.

Device Architectures and Design

Straintronics utilizes mechanical strain to manipulate electronic properties in device architectures, often employing flexible substrates and piezoelectric materials to induce strain-based modulation. Magnetoelectronics, or spintronics, relies on controlling electron spin within layered magnetic and non-magnetic structures, leveraging spin valves and magnetic tunnel junctions for data storage and logic applications. Your choice between these technologies depends on design priorities like energy efficiency, device scalability, and integration with existing semiconductor processes.

Energy Efficiency Comparison

Straintronics leverages mechanical strain to manipulate electronic properties with minimal energy input, resulting in significantly lower power consumption compared to Magnetoelectronics, which relies on magnetic field manipulation. The energy efficiency of Straintronics is enhanced due to reduced Joule heating and slower energy dissipation rates, making it ideal for low-power device applications. Your choice between these technologies depends on the desired balance between speed, scalability, and energy saving requirements.

Applications in Next-Generation Electronics

Straintronics exploits mechanical strain to control electronic properties in devices, enabling ultra-low-power memory and logic applications, making it ideal for flexible electronics and wearable technology. Magnetoelectronics leverages magnetic states for data storage and spintronic devices, offering high-speed, non-volatile memory solutions crucial for next-generation computing systems. Your choice between straintronics and magnetoelectronics depends on requirements for power efficiency, speed, and integration in advanced electronics.

Performance Metrics and Scalability

Straintronics offers superior energy efficiency and faster switching speeds compared to magnetoelectronics, making it promising for low-power, high-performance applications. Magnetoelectronics provides robust scalability due to established material fabrication techniques and integration with existing semiconductor processes. Your choice depends on whether minimizing power consumption or leveraging scalability for mass production is the critical factor.

Current Challenges and Research Directions

Straintronics faces challenges in controlling strain-induced effects at the nanoscale and integrating with existing semiconductor technology, requiring advanced materials engineering and device design. Magnetoelectronics struggles with efficient manipulation of magnetic states and reducing energy consumption, pushing research towards novel magnetic materials and spintronic mechanisms. Both fields are exploring hybrid approaches to overcome limitations, aiming to enhance performance in next-generation memory and logic devices.

Future Prospects and Industry Impact

Straintronics leverages mechanical deformation to control electronic properties, offering low-energy, ultra-fast switching potential crucial for next-generation flexible electronics and wearable devices. Magnetoelectronics exploits spin-dependent phenomena to enable high-density data storage and advanced spintronic memory with robust non-volatile characteristics, driving innovation in quantum computing and magnetic sensors. Both technologies promise transformative impacts across semiconductor, data storage, and IoT industries, with straintronics excelling in energy efficiency and magnetoelectronics advancing high-performance spin-based applications.

Straintronics vs Magnetoelectronics Infographic

electrown.com

electrown.com