Nanoparticle sensors offer high surface area and enhanced sensitivity for detecting chemical or biological substances, while nanowire sensors provide superior electrical conductivity and real-time signal transduction capabilities. Explore the rest of the article to understand which sensor technology best suits your specific application needs.

Table of Comparison

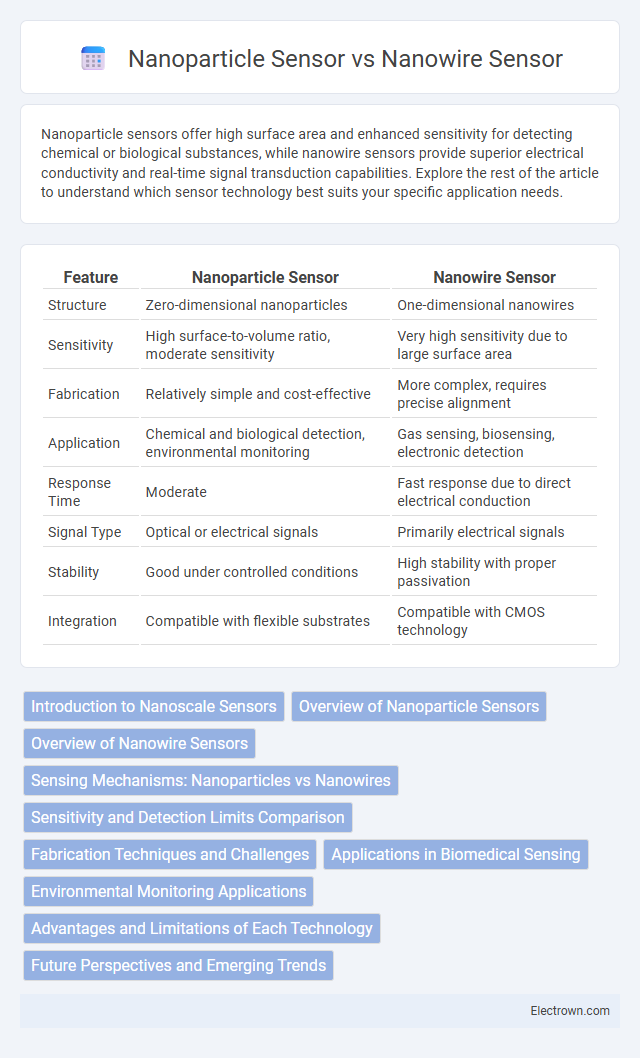

| Feature | Nanoparticle Sensor | Nanowire Sensor |

|---|---|---|

| Structure | Zero-dimensional nanoparticles | One-dimensional nanowires |

| Sensitivity | High surface-to-volume ratio, moderate sensitivity | Very high sensitivity due to large surface area |

| Fabrication | Relatively simple and cost-effective | More complex, requires precise alignment |

| Application | Chemical and biological detection, environmental monitoring | Gas sensing, biosensing, electronic detection |

| Response Time | Moderate | Fast response due to direct electrical conduction |

| Signal Type | Optical or electrical signals | Primarily electrical signals |

| Stability | Good under controlled conditions | High stability with proper passivation |

| Integration | Compatible with flexible substrates | Compatible with CMOS technology |

Introduction to Nanoscale Sensors

Nanoparticle sensors utilize tiny particles typically between 1 and 100 nanometers in size, offering high surface-to-volume ratios that enhance chemical and biological detection sensitivity. Nanowire sensors, composed of ultra-thin wires with diameters in the nanometer range, provide exceptional electrical conductivity and real-time signal transduction capabilities. Your choice between these nanoscale sensors depends on the specific application requirements involving sensitivity, selectivity, and response time.

Overview of Nanoparticle Sensors

Nanoparticle sensors utilize nanoscale particles, often composed of metals like gold or silver, to detect chemical or biological agents through changes in optical, electrical, or magnetic properties. These sensors excel in high surface area-to-volume ratios, which enhances sensitivity and allows for rapid, real-time detection of trace analytes. Compared to nanowire sensors, nanoparticle sensors offer greater versatility in functionalization and integration into various sensing platforms for environmental monitoring, medical diagnostics, and industrial applications.

Overview of Nanowire Sensors

Nanowire sensors utilize one-dimensional nanostructures with high surface-to-volume ratios, enhancing their sensitivity to chemical and biological analytes. Their unique electrical properties allow for real-time, label-free detection, making them ideal for applications in environmental monitoring, medical diagnostics, and wearable devices. You can benefit from their rapid response and miniaturized design for precise and efficient sensing solutions.

Sensing Mechanisms: Nanoparticles vs Nanowires

Nanoparticle sensors utilize the large surface-to-volume ratio of nanoparticles to enhance sensitivity through localized surface plasmon resonance and surface charge interactions, enabling efficient detection of chemical and biological analytes. Nanowire sensors operate based on changes in electrical conductivity triggered by adsorption of target molecules along their high-aspect-ratio structure, providing rapid and highly sensitive electronic transduction. The fundamental difference lies in nanoparticles leveraging optical and surface phenomena, while nanowires primarily utilize conductance modulation for sensing applications.

Sensitivity and Detection Limits Comparison

Nanoparticle sensors offer high surface-to-volume ratios that enhance their sensitivity, making them ideal for detecting low concentrations of analytes. Nanowire sensors provide superior electrical conductance changes upon analyte binding, resulting in even lower detection limits compared to nanoparticle sensors. You can achieve more precise and rapid detection with nanowire sensors in applications requiring ultra-sensitive monitoring.

Fabrication Techniques and Challenges

Nanoparticle sensors typically rely on chemical synthesis methods such as wet chemistry and self-assembly, enabling precise control over particle size and surface functionalization but often facing challenges in uniformity and scalability. Nanowire sensors are commonly fabricated using top-down techniques like electron beam lithography or bottom-up approaches such as vapor-liquid-solid (VLS) growth, offering high aspect ratios and sensitivity while encountering difficulties in integrating with existing semiconductor processes and achieving reproducible alignment. Both sensor types demand advanced nanofabrication expertise to overcome challenges related to material defects, device stability, and large-scale manufacturing for reliable sensing performance.

Applications in Biomedical Sensing

Nanoparticle sensors excel in biomedical sensing for their high surface-to-volume ratio and enhanced sensitivity in detecting biomolecules such as proteins and DNA, making them ideal for early disease diagnostics. Nanowire sensors offer superior electrical conductivity and real-time monitoring capabilities, enabling precise detection of glucose levels, cancer markers, and neurotransmitters at low concentrations. Both sensor types are integral in developing wearable health devices and implantable biosensors for continuous patient monitoring.

Environmental Monitoring Applications

Nanoparticle sensors offer high surface area-to-volume ratios, enhancing sensitivity in detecting trace environmental pollutants such as heavy metals and volatile organic compounds. Nanowire sensors provide superior electrical conductivity and direct charge transport, enabling rapid, real-time monitoring of air and water quality. For your environmental monitoring applications, selecting between these sensors depends on the required detection limits and response times for accurate pollutant analysis.

Advantages and Limitations of Each Technology

Nanoparticle sensors offer high surface-to-volume ratios that enhance sensitivity and enable rapid detection of chemical and biological molecules, but they face challenges in stability and reproducibility due to aggregation and surface variability. Nanowire sensors provide excellent electrical conductivity and directional charge transport, facilitating real-time, label-free detection with high signal-to-noise ratios; however, they often require complex fabrication processes and can suffer from mechanical fragility. Both technologies excel in nanoscale sensing applications, yet nanoparticle sensors are preferred for multiplexed detection while nanowire sensors are favored for integration into microelectronic devices.

Future Perspectives and Emerging Trends

Nanoparticle sensors offer enhanced surface-to-volume ratios and tunable chemical properties, making them ideal for ultra-sensitive detection in biomedical and environmental applications. Nanowire sensors provide superior electrical conductivity and faster electron transport, which supports real-time monitoring and integration into flexible electronics. Your choice between these technologies will influence the development of portable and wearable sensor devices driven by advancements in nanofabrication and material science.

Nanoparticle Sensor vs Nanowire Sensor Infographic

electrown.com

electrown.com