Nanoscale capacitors store and release electrical energy through electric fields generated between tiny conductive plates, enabling high-speed charge storage in ultra-compact designs, while nanoscale inductors rely on magnetic fields created by current loops to regulate and filter signals at the nanoscale. Discover how these components influence your next-gen electronic devices by reading the rest of this article.

Table of Comparison

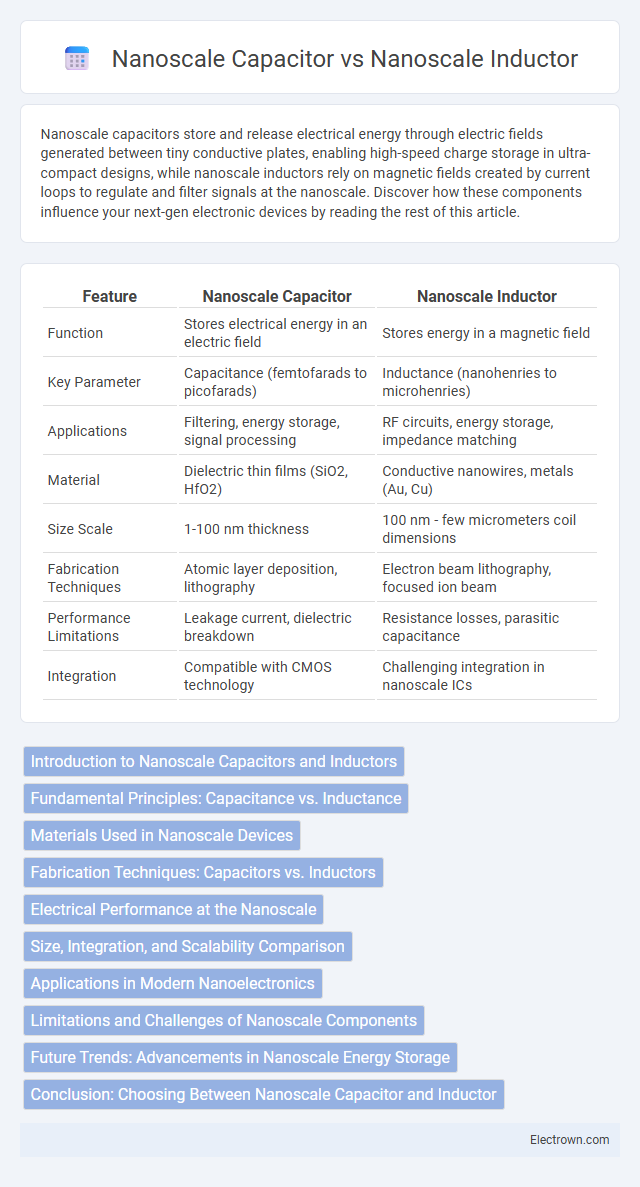

| Feature | Nanoscale Capacitor | Nanoscale Inductor |

|---|---|---|

| Function | Stores electrical energy in an electric field | Stores energy in a magnetic field |

| Key Parameter | Capacitance (femtofarads to picofarads) | Inductance (nanohenries to microhenries) |

| Applications | Filtering, energy storage, signal processing | RF circuits, energy storage, impedance matching |

| Material | Dielectric thin films (SiO2, HfO2) | Conductive nanowires, metals (Au, Cu) |

| Size Scale | 1-100 nm thickness | 100 nm - few micrometers coil dimensions |

| Fabrication Techniques | Atomic layer deposition, lithography | Electron beam lithography, focused ion beam |

| Performance Limitations | Leakage current, dielectric breakdown | Resistance losses, parasitic capacitance |

| Integration | Compatible with CMOS technology | Challenging integration in nanoscale ICs |

Introduction to Nanoscale Capacitors and Inductors

Nanoscale capacitors store electric energy in ultra-thin dielectric layers, enabling high capacitance density essential for miniaturized electronic devices. Nanoscale inductors generate magnetic fields with nanoscale conductive coils, vital for high-frequency signal processing and energy storage in compact circuits. Understanding your choice between these components impacts the performance and integration of nanoscale electronic systems.

Fundamental Principles: Capacitance vs. Inductance

Nanoscale capacitors store energy by accumulating electric charge on conductive plates separated by a dielectric material, characterized by capacitance which depends on plate area, separation distance, and dielectric constant. Nanoscale inductors store energy in a magnetic field generated by electric current flowing through a coil, with inductance determined by factors such as coil geometry, number of turns, and magnetic permeability. The fundamental distinction lies in capacitors reacting to voltage changes by storing charge, whereas inductors oppose current changes by inducing magnetic flux.

Materials Used in Nanoscale Devices

Nanoscale capacitors commonly use high-k dielectric materials such as hafnium oxide (HfO2) and aluminum oxide (Al2O3) to enhance capacitance and reduce leakage currents. Nanoscale inductors often incorporate ferromagnetic materials like cobalt (Co) and nickel-iron alloys (NiFe) to improve magnetic permeability and inductance density. Advanced fabrication techniques enable the integration of these materials into nanostructures, optimizing device performance for energy storage and signal processing applications.

Fabrication Techniques: Capacitors vs. Inductors

Nanoscale capacitors are typically fabricated using advanced thin-film deposition methods such as atomic layer deposition (ALD) and chemical vapor deposition (CVD), enabling precise control over dielectric thickness and electrode morphology. In contrast, nanoscale inductors often require complex lithography techniques combined with focused ion beam (FIB) milling or electron beam lithography (EBL) to create intricate spiral or solenoid coil structures with minimal resistance and high Q factors. Your choice between these components depends on the fabrication capabilities matched to device integration and performance requirements.

Electrical Performance at the Nanoscale

Nanoscale capacitors provide high capacitance density with fast charge and discharge cycles, ideal for energy storage and signal filtering in compact electronic devices. Nanoscale inductors, while critical for energy transfer and magnetic field generation, tend to face challenges like reduced inductance and increased resistance due to quantum effects and fabrication limitations. Your choice between these components depends on balancing capacitance and inductance requirements with the specific electrical performance constraints of nanoscale integration.

Size, Integration, and Scalability Comparison

Nanoscale capacitors typically exhibit smaller sizes than nanoscale inductors due to their planar structures, enabling more efficient integration in compact circuits and high-density chip designs. Integration of nanoscale capacitors is facilitated by mature fabrication techniques compatible with advanced CMOS processes, whereas nanoscale inductors often demand more complex three-dimensional structures, limiting seamless on-chip integration. Scalability favors nanoscale capacitors as they maintain consistent performance with size reduction, while nanoscale inductors face challenges such as reduced inductance and increased parasitic losses, impacting their effectiveness in highly scaled applications.

Applications in Modern Nanoelectronics

Nanoscale capacitors are critical in energy storage and filtering within high-frequency circuits, enhancing signal integrity in advanced nanoelectronic devices like RF transceivers and nanoscale sensors. Nanoscale inductors provide essential magnetic field generation and energy transfer capabilities, improving performance in nano-oscillators, transformers, and wireless power systems. Both components enable miniaturization and increased efficiency in integrated circuits, supporting the development of next-generation wearable electronics, IoT devices, and quantum computing architectures.

Limitations and Challenges of Nanoscale Components

Nanoscale capacitors face significant challenges such as dielectric breakdown, leakage currents, and reduced capacitance due to quantum tunneling effects at ultra-thin dielectric layers. Nanoscale inductors struggle with parasitic resistances, limited quality factor (Q), and magnetic field confinement, which degrade their performance in high-frequency applications. Both components encounter fabrication reliability issues and scaling constraints that hinder their integration into advanced nanoelectronic circuits.

Future Trends: Advancements in Nanoscale Energy Storage

Future trends in nanoscale capacitor and inductor technology emphasize enhanced energy density and faster charge-discharge cycles achieved through innovative materials like graphene and transition metal dichalcogenides. Nanoscale capacitors show promise in integrating with flexible electronics due to their high power density and rapid response, while nanoscale inductors benefit from miniaturization and magnetic property optimization for efficient energy conversion. These advancements drive the development of compact, high-performance energy storage and management systems critical for next-generation wearable devices and IoT applications.

Conclusion: Choosing Between Nanoscale Capacitor and Inductor

Selecting between a nanoscale capacitor and a nanoscale inductor depends largely on the specific application requirements such as frequency response, energy storage, and size constraints. Nanoscale capacitors excel in high-frequency circuits and energy storage due to their ability to maintain high capacitance in a minimal footprint, while nanoscale inductors are preferred for filtering and signal processing where magnetic field interactions are crucial. Performance trade-offs, integration complexity, and fabrication techniques ultimately dictate the optimal choice for nanoelectronic devices.

Nanoscale Capacitor vs Nanoscale Inductor Infographic

electrown.com

electrown.com