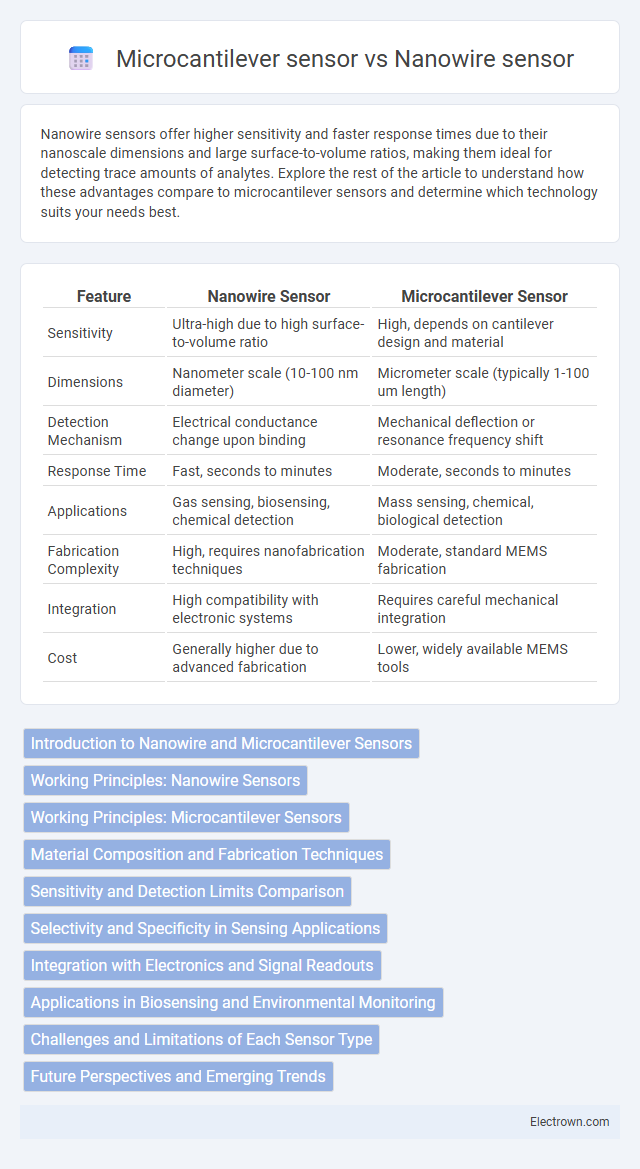

Nanowire sensors offer higher sensitivity and faster response times due to their nanoscale dimensions and large surface-to-volume ratios, making them ideal for detecting trace amounts of analytes. Explore the rest of the article to understand how these advantages compare to microcantilever sensors and determine which technology suits your needs best.

Table of Comparison

| Feature | Nanowire Sensor | Microcantilever Sensor |

|---|---|---|

| Sensitivity | Ultra-high due to high surface-to-volume ratio | High, depends on cantilever design and material |

| Dimensions | Nanometer scale (10-100 nm diameter) | Micrometer scale (typically 1-100 um length) |

| Detection Mechanism | Electrical conductance change upon binding | Mechanical deflection or resonance frequency shift |

| Response Time | Fast, seconds to minutes | Moderate, seconds to minutes |

| Applications | Gas sensing, biosensing, chemical detection | Mass sensing, chemical, biological detection |

| Fabrication Complexity | High, requires nanofabrication techniques | Moderate, standard MEMS fabrication |

| Integration | High compatibility with electronic systems | Requires careful mechanical integration |

| Cost | Generally higher due to advanced fabrication | Lower, widely available MEMS tools |

Introduction to Nanowire and Microcantilever Sensors

Nanowire sensors utilize nanoscale conductive filaments that exhibit high surface-to-volume ratios, enabling exceptional sensitivity to chemical and biological stimuli. Microcantilever sensors operate based on the deflection or resonance frequency shifts of microscopic cantilever beams in response to surface stress changes caused by analyte interactions. Your choice between nanowire and microcantilever sensors should consider factors such as sensitivity requirements, detection environment, and integration capabilities within your application.

Working Principles: Nanowire Sensors

Nanowire sensors operate based on changes in electrical conductivity caused by the interaction of target molecules with the nanowire surface, which alters charge carrier density in the semiconductor material. These sensors leverage the high surface-to-volume ratio of nanowires, making them extremely sensitive to chemical or biological agents at low concentrations. Your detection system's performance improves significantly with nanowire sensors due to their ability to provide real-time, label-free sensing with rapid response times.

Working Principles: Microcantilever Sensors

Microcantilever sensors detect chemical or biological substances by measuring changes in the cantilever's bending or resonance frequency caused by surface stress or mass loading. Adsorption of target molecules induces mechanical deflection or shifts in vibrational modes, enabling highly sensitive detection at nanoscale levels. These sensors leverage piezoresistive, optical, or piezoelectric transduction mechanisms to convert physical changes into measurable electrical signals.

Material Composition and Fabrication Techniques

Nanowire sensors are typically composed of semiconductor materials such as silicon, zinc oxide, or indium oxide, fabricated using bottom-up methods like chemical vapor deposition or electrochemical synthesis that enable control at the nanoscale. Microcantilever sensors often utilize silicon, silicon nitride, or polymers, produced through top-down microfabrication techniques like photolithography and etching, which provide precise dimensional control for mechanical sensing elements. The material properties and fabrication processes directly influence sensitivity, selectivity, and integration capabilities of nanowire and microcantilever sensor platforms.

Sensitivity and Detection Limits Comparison

Nanowire sensors exhibit superior sensitivity due to their high surface-to-volume ratio, enabling detection of analytes at femtomolar concentrations. Microcantilever sensors, while sensitive to surface stress changes, generally have higher detection limits, typically in the nanomolar range. The enhanced electronic properties and nanoscale dimensions of nanowires contribute to lower limits of detection compared to the mechanical deflection-based microcantilever approach.

Selectivity and Specificity in Sensing Applications

Nanowire sensors exhibit superior selectivity and specificity due to their high surface-to-volume ratio and tunable surface chemistry, enabling precise detection of target molecules even at low concentrations. Microcantilever sensors rely on mechanical deflection changes induced by molecular interactions, providing high specificity but often requiring surface functionalization to enhance selectivity for particular analytes. The choice between nanowire and microcantilever sensors depends on the required sensitivity and the complexity of the sensing environment, with nanowire sensors generally offering enhanced performance in differentiating closely related chemical species.

Integration with Electronics and Signal Readouts

Nanowire sensors offer high sensitivity and excellent compatibility with CMOS technology, enabling seamless integration with electronic circuits for real-time signal readouts and low-power operation. Microcantilever sensors, while sensitive to mechanical changes, often require complex optical or piezoresistive readout systems that can complicate miniaturization and signal processing. The nano-scale dimensions of nanowires facilitate direct electrical signal transduction, enhancing integration efficiency compared to the more intricate signal conversion steps needed in microcantilever sensors.

Applications in Biosensing and Environmental Monitoring

Nanowire sensors exhibit exceptional sensitivity and rapid response times, making them ideal for detecting trace biomolecules and pollutants in biosensing and environmental monitoring. Microcantilever sensors provide label-free detection by measuring mechanical deflections, enabling precise monitoring of biomolecular interactions and toxic contaminants in air and water. Both sensor types offer complementary advantages in real-time, high-resolution analysis for healthcare diagnostics and ecosystem protection.

Challenges and Limitations of Each Sensor Type

Nanowire sensors face challenges such as fabrication complexity, signal drift, and sensitivity to environmental factors like temperature and humidity, which can affect their reliability. Microcantilever sensors suffer from limited durability, susceptibility to mechanical noise, and difficulties in miniaturization that constrain their deployment in compact devices. Both sensor types require advanced surface functionalization techniques to enhance selectivity and reduce false positives in real-world applications.

Future Perspectives and Emerging Trends

Nanowire sensors exhibit exceptional sensitivity and miniaturization potential, making them ideal for next-generation wearable and implantable devices. Microcantilever sensors continue to advance in multiplexing capabilities and integration with microfluidic systems, enhancing real-time biomolecular detection. You can expect future developments to emphasize hybrid sensor platforms that leverage the high surface area of nanowires alongside the mechanical precision of microcantilevers for improved diagnostic and environmental monitoring applications.

Nanowire sensor vs Microcantilever sensor Infographic

electrown.com

electrown.com