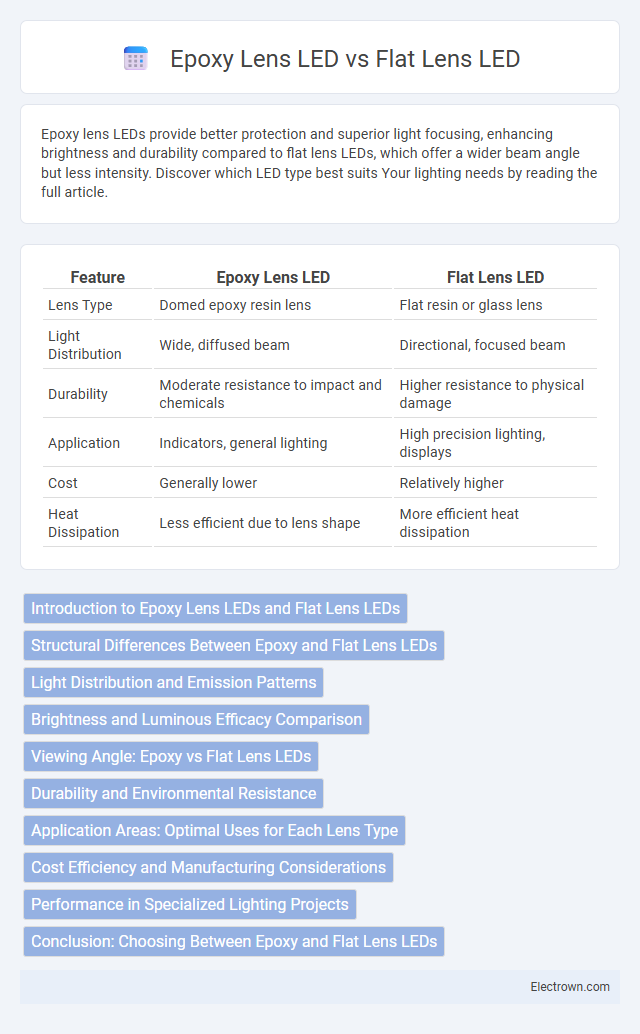

Epoxy lens LEDs provide better protection and superior light focusing, enhancing brightness and durability compared to flat lens LEDs, which offer a wider beam angle but less intensity. Discover which LED type best suits Your lighting needs by reading the full article.

Table of Comparison

| Feature | Epoxy Lens LED | Flat Lens LED |

|---|---|---|

| Lens Type | Domed epoxy resin lens | Flat resin or glass lens |

| Light Distribution | Wide, diffused beam | Directional, focused beam |

| Durability | Moderate resistance to impact and chemicals | Higher resistance to physical damage |

| Application | Indicators, general lighting | High precision lighting, displays |

| Cost | Generally lower | Relatively higher |

| Heat Dissipation | Less efficient due to lens shape | More efficient heat dissipation |

Introduction to Epoxy Lens LEDs and Flat Lens LEDs

Epoxy lens LEDs feature a dome-shaped epoxy resin encapsulation that enhances light diffusion and protection, making them ideal for general lighting and indicator applications. Flat lens LEDs possess a smooth, planar lens surface designed to direct light more precisely, improving beam control and efficiency in focused lighting tasks. Both types optimize LED performance by balancing light output, durability, and application-specific requirements.

Structural Differences Between Epoxy and Flat Lens LEDs

Epoxy lens LEDs feature a dome-shaped, clear epoxy encapsulation that acts as both a protective layer and a light-focusing element, enhancing light intensity and beam angle control. Flat lens LEDs utilize a flat, often silicone or plastic lens that provides a more uniform, diffused light output with less directional focus. Structural variations in the encapsulant shape and material significantly influence the optical performance and heat dissipation characteristics of each LED type.

Light Distribution and Emission Patterns

Epoxy lens LEDs typically feature a domed design that concentrates light in a narrower beam, providing a focused emission pattern ideal for applications requiring directional illumination. Flat lens LEDs offer broader light distribution with wide viewing angles, resulting in more uniform illumination across surfaces, which is beneficial for ambient lighting. The choice between epoxy and flat lens LEDs hinges on the desired light distribution, with epoxy lenses optimizing intensity and flat lenses enhancing coverage.

Brightness and Luminous Efficacy Comparison

Epoxy lens LEDs typically offer higher brightness due to their superior light-focusing capabilities, enhancing luminous intensity compared to flat lens LEDs. Flat lens LEDs provide broader light distribution but with lower luminous efficacy, making them less efficient for applications requiring concentrated illumination. Choosing the right lens type impacts your lighting performance by balancing brightness and energy efficiency based on specific needs.

Viewing Angle: Epoxy vs Flat Lens LEDs

Epoxy lens LEDs typically offer wider viewing angles ranging from 120deg to 160deg, allowing for broader light dispersion and uniform illumination over larger areas. Flat lens LEDs generally provide narrower viewing angles between 30deg and 90deg, resulting in more focused and intense directional light suitable for spotlighting applications. The choice between epoxy and flat lens LEDs depends on the desired beam spread and application requirements, with epoxy lenses favored for ambient lighting and flat lenses for targeted lighting.

Durability and Environmental Resistance

Epoxy lens LEDs offer superior durability and environmental resistance due to their robust encapsulating material, which protects against moisture, dust, and mechanical impact. Flat lens LEDs, while sleek and lightweight, typically have less effective sealing, making them more vulnerable to harsh conditions and reducing their long-term reliability. If your application demands enhanced protection and longevity, choosing epoxy lens LEDs can ensure better performance in challenging environments.

Application Areas: Optimal Uses for Each Lens Type

Epoxy lens LEDs excel in outdoor lighting, automotive headlights, and industrial applications due to their robust protection against moisture and mechanical damage. Flat lens LEDs are ideal for indoor lighting, displays, and backlighting where precise beam control and uniform light distribution are critical. Selecting epoxy lenses enhances durability in harsh environments, while flat lenses optimize visual clarity and light quality in controlled settings.

Cost Efficiency and Manufacturing Considerations

Epoxy lens LEDs typically offer lower production costs due to simpler molding processes and less stringent material requirements, making them cost-efficient for mass manufacturing. Flat lens LEDs demand higher precision in fabrication and more expensive, high-quality materials to ensure optimal light distribution and thermal performance, increasing manufacturing complexity and expenses. Choosing between epoxy and flat lens LEDs depends on balancing budget constraints with desired optical performance and long-term reliability in production.

Performance in Specialized Lighting Projects

Epoxy lens LEDs offer superior durability and better light diffusion, making them ideal for specialized lighting projects where uniform illumination and resistance to environmental factors are crucial. Flat lens LEDs provide a more focused beam and higher intensity, suited for applications requiring precise light direction and enhanced brightness. Your choice depends on whether your project prioritizes broad, even light distribution or targeted, high-intensity illumination.

Conclusion: Choosing Between Epoxy and Flat Lens LEDs

Epoxy lens LEDs offer superior durability and enhanced light diffusion, making them ideal for applications requiring robust performance and wide beam angles. Flat lens LEDs provide sharper, more focused illumination suited for precision lighting tasks where minimal light scattering is preferred. Selecting between epoxy and flat lens LEDs depends on balancing requirements for durability, beam spread, and application-specific lighting precision.

Epoxy lens LED vs Flat lens LED Infographic

electrown.com

electrown.com