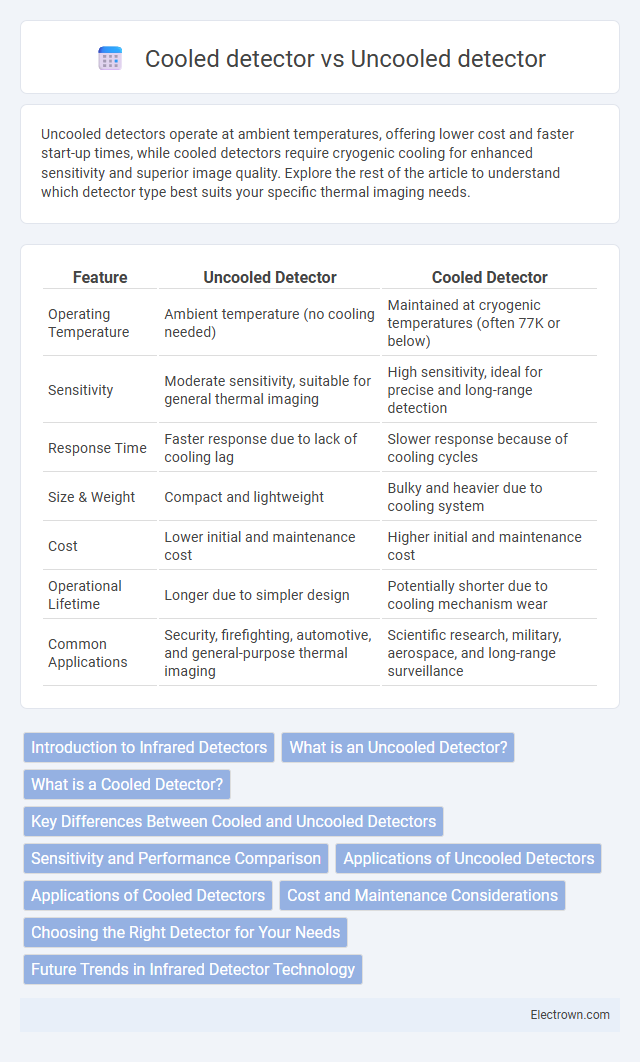

Uncooled detectors operate at ambient temperatures, offering lower cost and faster start-up times, while cooled detectors require cryogenic cooling for enhanced sensitivity and superior image quality. Explore the rest of the article to understand which detector type best suits your specific thermal imaging needs.

Table of Comparison

| Feature | Uncooled Detector | Cooled Detector |

|---|---|---|

| Operating Temperature | Ambient temperature (no cooling needed) | Maintained at cryogenic temperatures (often 77K or below) |

| Sensitivity | Moderate sensitivity, suitable for general thermal imaging | High sensitivity, ideal for precise and long-range detection |

| Response Time | Faster response due to lack of cooling lag | Slower response because of cooling cycles |

| Size & Weight | Compact and lightweight | Bulky and heavier due to cooling system |

| Cost | Lower initial and maintenance cost | Higher initial and maintenance cost |

| Operational Lifetime | Longer due to simpler design | Potentially shorter due to cooling mechanism wear |

| Common Applications | Security, firefighting, automotive, and general-purpose thermal imaging | Scientific research, military, aerospace, and long-range surveillance |

Introduction to Infrared Detectors

Infrared detectors are essential components in thermal imaging systems, converting infrared radiation into electrical signals. Uncooled detectors operate at ambient temperatures using materials like microbolometers, offering faster startup times and lower power consumption but typically lower sensitivity. Cooled detectors require cryogenic cooling to enhance performance with higher sensitivity and resolution, making them suitable for advanced applications such as military surveillance and scientific research.

What is an Uncooled Detector?

An uncooled detector is a thermal imaging sensor that operates at ambient temperature without the need for cryogenic cooling systems, making it more compact and cost-effective than cooled detectors. It utilizes materials like vanadium oxide (VOx) or amorphous silicon (a-Si) to detect infrared radiation by measuring temperature changes, enabling reliable thermal images in various applications. Your choice of an uncooled detector offers quicker startup times and reduced maintenance, ideal for budget-conscious or portable thermal imaging systems.

What is a Cooled Detector?

A cooled detector is a type of infrared sensor that operates at very low temperatures using cryogenic cooling to significantly reduce thermal noise, enhancing sensitivity and image clarity. These detectors typically employ materials like mercury cadmium telluride (MCT) or indium antimonide (InSb) and are essential in high-performance applications such as military targeting, scientific research, and aerospace. Cooling allows the detector to capture finer temperature differences, resulting in superior resolution and precision compared to uncooled detectors.

Key Differences Between Cooled and Uncooled Detectors

Cooled detectors operate at cryogenic temperatures, significantly reducing thermal noise and providing higher sensitivity and resolution, ideal for precise thermal imaging applications. Uncooled detectors function at ambient temperature using materials like microbolometers, offering faster response times and lower cost but with reduced sensitivity. Your choice between cooled and uncooled detectors depends on the required image quality, application, and budget constraints.

Sensitivity and Performance Comparison

Uncooled detectors typically offer moderate sensitivity with lower power consumption, making them suitable for general thermal imaging applications where cost and robustness are priorities. Cooled detectors provide significantly higher sensitivity and faster response times due to their cryogenic cooling systems, enhancing performance in low-contrast and long-range detection scenarios. Your choice depends on the required thermal resolution and environmental conditions, as cooled detectors excel in precision but demand more complex maintenance.

Applications of Uncooled Detectors

Uncooled detectors are widely used in applications such as building inspections, firefighting, and security surveillance due to their lower cost, portability, and ability to operate without cryogenic cooling. These detectors excel in environments requiring continuous thermal imaging for condition monitoring or predictive maintenance, where rapid deployment and reliability are crucial. Your choice of uncooled detectors can enhance efficiency and responsiveness in fields like energy audits and automotive night vision systems.

Applications of Cooled Detectors

Cooled detectors are widely used in high-precision applications such as astronomy, military surveillance, and scientific research due to their superior sensitivity and lower noise levels compared to uncooled detectors. These detectors operate at cryogenic temperatures to significantly enhance infrared signal detection, making them ideal for thermal imaging, spectroscopy, and nighttime target identification. Their ability to detect faint infrared signatures enables advanced functionalities in space exploration and missile tracking systems.

Cost and Maintenance Considerations

Uncooled detectors generally offer lower upfront costs and reduced maintenance requirements compared to cooled detectors, making them more cost-effective for budget-sensitive projects. Cooled detectors require complex cooling systems, such as Stirling engines or liquid nitrogen, leading to higher installation and operational expenses. Maintenance for cooled detectors involves regular servicing of cooling components, while uncooled detectors benefit from simplified designs with minimal maintenance needs.

Choosing the Right Detector for Your Needs

Uncooled detectors offer affordable, compact, and low-maintenance infrared sensing ideal for general-purpose applications, while cooled detectors provide higher sensitivity and faster response times necessary for precision tasks such as military targeting or scientific research. Your specific use case, including budget constraints, environmental conditions, and required detection range, will determine the best choice between these technologies. Understanding the trade-offs in performance, cost, and durability helps ensure optimal detector selection for accurate and reliable thermal imaging results.

Future Trends in Infrared Detector Technology

Uncooled detectors offer advantages in cost, size, and power consumption, making them increasingly popular in commercial and industrial applications, while cooled detectors continue to provide superior sensitivity and spectral range for high-performance military and scientific uses. Future trends indicate a convergence where uncooled technologies will improve in sensitivity and noise reduction, narrowing the performance gap with cooled detectors through advancements in materials like vanadium oxide and microbolometers. Your choice between uncooled and cooled infrared detectors will increasingly depend on balancing application-specific requirements with ongoing innovations in detector efficiency and integration capabilities.

Uncooled detector vs Cooled detector Infographic

electrown.com

electrown.com