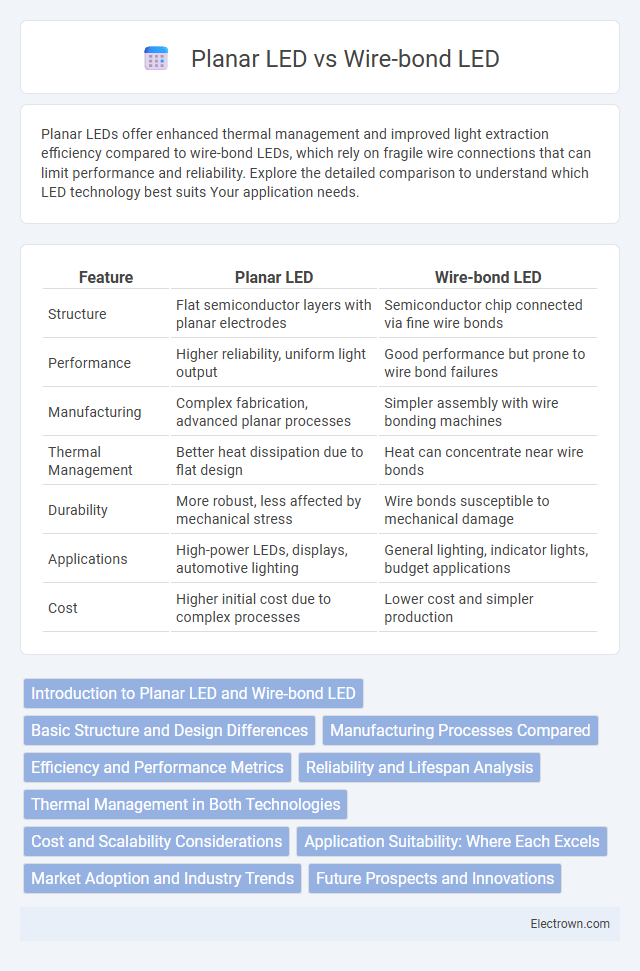

Planar LEDs offer enhanced thermal management and improved light extraction efficiency compared to wire-bond LEDs, which rely on fragile wire connections that can limit performance and reliability. Explore the detailed comparison to understand which LED technology best suits Your application needs.

Table of Comparison

| Feature | Planar LED | Wire-bond LED |

|---|---|---|

| Structure | Flat semiconductor layers with planar electrodes | Semiconductor chip connected via fine wire bonds |

| Performance | Higher reliability, uniform light output | Good performance but prone to wire bond failures |

| Manufacturing | Complex fabrication, advanced planar processes | Simpler assembly with wire bonding machines |

| Thermal Management | Better heat dissipation due to flat design | Heat can concentrate near wire bonds |

| Durability | More robust, less affected by mechanical stress | Wire bonds susceptible to mechanical damage |

| Applications | High-power LEDs, displays, automotive lighting | General lighting, indicator lights, budget applications |

| Cost | Higher initial cost due to complex processes | Lower cost and simpler production |

Introduction to Planar LED and Wire-bond LED

Planar LEDs feature a flat, layered semiconductor structure that enables uniform light emission and improved heat dissipation, making them suitable for high-efficiency lighting applications. Wire-bond LEDs utilize fine metal wires to connect the semiconductor chip to the external circuit, providing reliable electrical connections but often resulting in higher thermal resistance and potential failure points. Understanding the differences in design and performance characteristics between Planar and Wire-bond LEDs helps you select the optimal technology for your lighting project.

Basic Structure and Design Differences

Planar LEDs feature a flat, layered semiconductor structure allowing for uniform light emission and efficient heat dissipation, while wire-bond LEDs use discrete chip components connected by fine wires, leading to potential electrical resistance and reduced thermal performance. The planar design enables a more compact and robust LED assembly with fewer mechanical stresses, contrasted with the wire-bond design's reliance on fragile wire connections that can limit device longevity. Understanding these structural differences can help optimize Your choice for applications requiring higher reliability and consistent luminous output.

Manufacturing Processes Compared

Planar LED manufacturing involves depositing multiple layers on a flat substrate using photolithography and etching techniques, enabling high precision and uniformity. Wire-bond LED production requires assembling individual chips, followed by die bonding and wire bonding to connect the LED chip to the package, which can introduce variations in performance and reliability. Your choice between these technologies impacts production scalability and device consistency, with planar LEDs typically offering more streamlined, automated processes.

Efficiency and Performance Metrics

Planar LED technology offers higher luminous efficiency by minimizing electron leakage and enhancing current spreading compared to traditional wire-bond LEDs, resulting in improved light output and thermal management. Wire-bond LEDs often suffer from increased electrical resistance and thermal hotspots due to the bonding wires, which can reduce device reliability and limit peak performance. Optimizing your project with planar LEDs can lead to superior performance metrics such as higher radiant flux, longer operational lifespan, and better energy efficiency.

Reliability and Lifespan Analysis

Planar LEDs exhibit higher reliability and longer lifespan due to their robust structural design, which minimizes mechanical stress and thermal resistance compared to wire-bond LEDs. Wire-bond LEDs are prone to bond wire lift-off and breakage, leading to premature failure and reduced operational durability. Your choice of planar LED technology enhances device longevity and consistent performance in demanding applications.

Thermal Management in Both Technologies

Planar LED technology offers superior thermal management due to its large surface area, which allows for efficient heat dissipation and reduces the risk of thermal degradation. Wire-bond LEDs rely on wire connections that can trap heat and create hotspots, often requiring additional cooling solutions to maintain optimal performance. You benefit from improved reliability and longer lifespan when choosing planar LEDs for applications demanding effective thermal control.

Cost and Scalability Considerations

Planar LEDs offer lower manufacturing costs due to simpler fabrication processes and reduced material waste compared to wire-bond LEDs, which require more intricate assembly and higher labor intensity. Scalability favors planar LEDs as their design supports mass production with consistent quality, while wire-bond LEDs face limitations from complex wiring and alignment challenges. If your project demands efficient scaling and cost-effectiveness, planar LEDs present a more advantageous solution.

Application Suitability: Where Each Excels

Planar LEDs excel in applications requiring high reliability and uniform light distribution, such as automotive headlights and large-area displays, due to their robust structure and efficient heat dissipation. Wire-bond LEDs are more suitable for compact electronic devices and intricate circuit designs where cost-effectiveness and flexibility in chip placement are critical. Your choice depends on whether durability and thermal management or design flexibility and cost are the primary priorities.

Market Adoption and Industry Trends

Planar LED technology is gaining rapid market adoption due to its enhanced thermal management and higher luminous efficiency compared to traditional wire-bond LEDs. Industry trends show a significant shift towards planar LEDs in automotive lighting, displays, and advanced signaling applications, driven by their reliability and compact design. Wire-bond LEDs, while still prevalent in cost-sensitive segments, face declining demand as planar LEDs offer superior performance and integration capabilities in emerging high-tech sectors.

Future Prospects and Innovations

Planar LED technology offers superior thermal management and enhanced light uniformity compared to Wire-bond LED, positioning it as a key player in next-generation display and lighting applications. Innovations in planar structures enable higher integration density and improved reliability, addressing the limitations of wire-bonding such as limited lifespan and mechanical fragility. Your future devices will likely benefit from the scalability and efficiency advancements driven by planar LED research, fueling growth in automotive, wearable, and micro-LED markets.

Planar LED vs Wire-bond LED Infographic

electrown.com

electrown.com