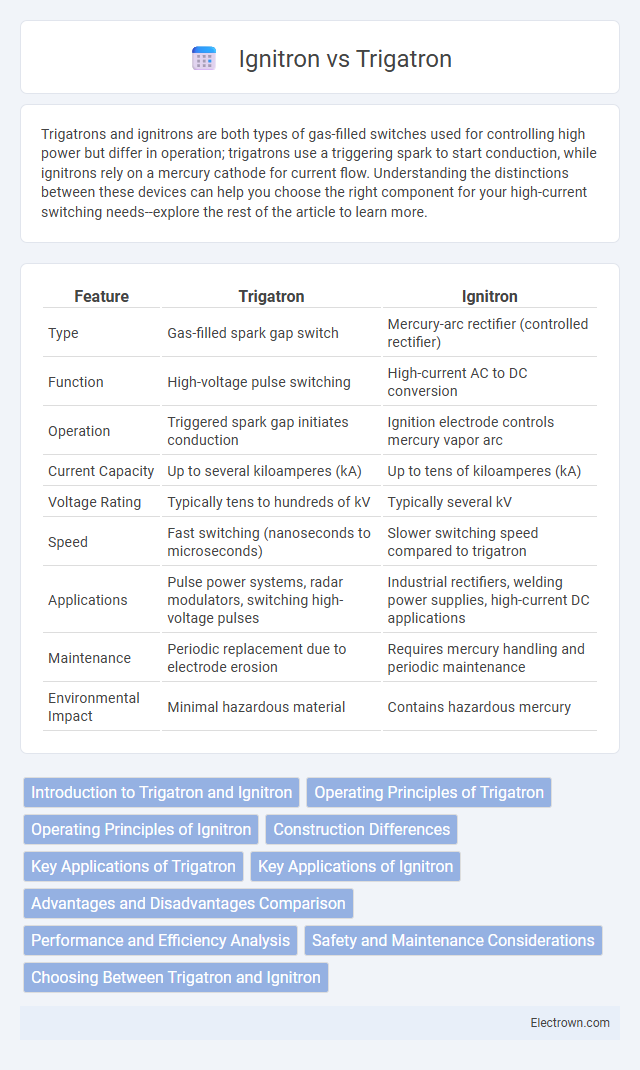

Trigatrons and ignitrons are both types of gas-filled switches used for controlling high power but differ in operation; trigatrons use a triggering spark to start conduction, while ignitrons rely on a mercury cathode for current flow. Understanding the distinctions between these devices can help you choose the right component for your high-current switching needs--explore the rest of the article to learn more.

Table of Comparison

| Feature | Trigatron | Ignitron |

|---|---|---|

| Type | Gas-filled spark gap switch | Mercury-arc rectifier (controlled rectifier) |

| Function | High-voltage pulse switching | High-current AC to DC conversion |

| Operation | Triggered spark gap initiates conduction | Ignition electrode controls mercury vapor arc |

| Current Capacity | Up to several kiloamperes (kA) | Up to tens of kiloamperes (kA) |

| Voltage Rating | Typically tens to hundreds of kV | Typically several kV |

| Speed | Fast switching (nanoseconds to microseconds) | Slower switching speed compared to trigatron |

| Applications | Pulse power systems, radar modulators, switching high-voltage pulses | Industrial rectifiers, welding power supplies, high-current DC applications |

| Maintenance | Periodic replacement due to electrode erosion | Requires mercury handling and periodic maintenance |

| Environmental Impact | Minimal hazardous material | Contains hazardous mercury |

Introduction to Trigatron and Ignitron

Trigatron and ignitron are both types of high-power electrical switches used in pulsed power applications, but they differ in construction and operation. A trigatron is a gas-filled spark gap switch that uses a trigger electrode to initiate conduction, providing fast, reliable switching in circuits requiring high voltage and current. Ignitron is a mercury-arc rectifier switch where a pool of liquid mercury acts as the cathode, ideal for controlling very high currents with precise timing in industrial and power applications.

Operating Principles of Trigatron

Trigatrons operate by initiating a controlled arc discharge between electrodes through a trigger pulse applied to a third electrode, allowing high-current switching in pulse power applications. The trigger pulse ionizes the gas inside the switch, lowering its breakdown voltage and enabling rapid conduction. This principle enables trigatrons to handle high voltage and current transients efficiently, distinguishing them from ignitrons which use a mercury vapor arc initiated by heating a cathode.

Operating Principles of Ignitron

Ignitrons operate as mercury-arc rectifiers utilizing a pool of liquid mercury as a cathode, with an igniting electrode to initiate conduction by creating an arc through ionized mercury vapor. Current flow is controlled by the timing and pulse of the igniting electrode, allowing precise triggering in high-current applications such as industrial power control and pulsed power systems. Unlike trigatrons, which rely on spark gaps to switch high voltage pulses rapidly, ignitrons provide efficient, controlled conduction with slower switching speeds but higher current capacity.

Construction Differences

Trigatrons feature a sealed glass or ceramic envelope containing three main electrodes--cathode, anode, and a trigger electrode--allowing controlled spark initiation for rapid switching. Ignitrons use a mercury-filled tube with a cathode rod immersed in a pool of liquid mercury, providing a robust arc for high-current conduction but requiring maintenance due to mercury handling. The trigatron's simpler solid or gas insulation contrasts with the ignitron's reliance on liquid mercury for arc initiation and stability, affecting durability and operational environments.

Key Applications of Trigatron

Trigatrons are primarily used as high-voltage, high-current switching devices in pulsed power systems, radar modulators, and particle accelerators due to their fast switching capabilities and robustness. Their ability to handle rapid, repetitive switching makes them ideal for triggering large electrical discharges in industrial applications such as lightning simulation and plasma generation. Unlike ignitrons, which function well in rectification and controlled rectifier applications, trigatrons excel in switching operations requiring precise timing and high power handling.

Key Applications of Ignitron

Ignitrons are primarily used in high-current industrial applications such as electric arc welding, controlled rectifiers in power plants, and large motor control systems due to their ability to handle substantial current loads with reliable conduction. Their robust design ensures efficient performance in pulsed power operations, making them ideal for use in capacitor discharge systems and pulse modulators. Unlike trigatrons, ignitrons excel in continuous high-current control rather than fast switching, positioning them as essential components in heavy electrical engineering and power distribution industries.

Advantages and Disadvantages Comparison

Trigatrons provide faster switching speeds and higher peak current handling, making them ideal for pulsed power applications, while ignitrons excel in heavy-duty, continuous current conduction with robust arc ignition. Trigatrons have simpler construction and faster recovery times but suffer from lower durability and shorter lifespan compared to the more rugged ignitrons. Ignitrons require precise control of arc initiation and have slower switching speeds, limiting their use in high-frequency applications despite their superior current capacity and reliability.

Performance and Efficiency Analysis

Trigatrons offer faster switching speeds and better performance in high-voltage pulse applications compared to ignitrons, which are bulkier and have slower response times. Ignitrons excel in handling high current loads with robust durability but have lower efficiency due to greater energy losses during conduction. Your choice between trigatron and ignitron should consider the balance between speed, voltage rating, and current capacity for optimal system efficiency.

Safety and Maintenance Considerations

Trigatrons offer enhanced safety with their sealed gas-filled design, reducing the risk of arc flash and minimizing maintenance requirements compared to ignitrons. Ignitrons require regular inspection and replacement of mercury, posing environmental and health hazards that demand careful handling and disposal procedures. You benefit from lower operational risks and simpler upkeep when choosing trigatrons for high-voltage switching applications.

Choosing Between Trigatron and Ignitron

Choosing between a trigatron and an ignitron depends on your application's voltage, current requirements, and switching speed. Trigatrons excel in rapid switching and are ideal for high-voltage pulse circuits, while ignitrons handle higher current loads with robust conduction but slower switching. Understanding your circuit's demands ensures you select the optimal device for reliable performance.

trigatron vs ignitron Infographic

electrown.com

electrown.com