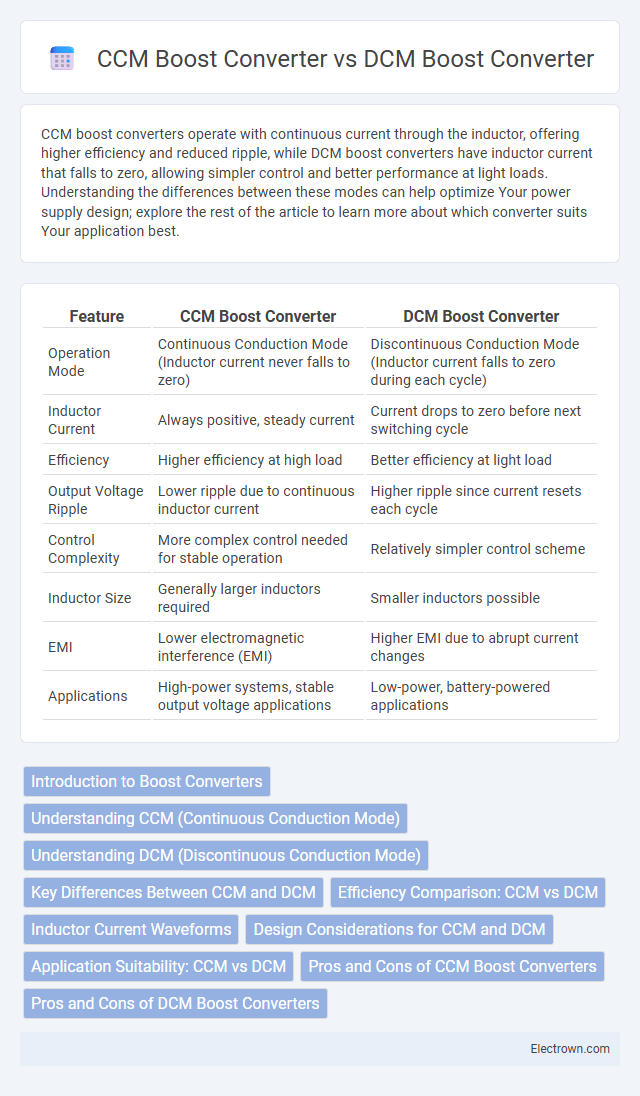

CCM boost converters operate with continuous current through the inductor, offering higher efficiency and reduced ripple, while DCM boost converters have inductor current that falls to zero, allowing simpler control and better performance at light loads. Understanding the differences between these modes can help optimize Your power supply design; explore the rest of the article to learn more about which converter suits Your application best.

Table of Comparison

| Feature | CCM Boost Converter | DCM Boost Converter |

|---|---|---|

| Operation Mode | Continuous Conduction Mode (Inductor current never falls to zero) | Discontinuous Conduction Mode (Inductor current falls to zero during each cycle) |

| Inductor Current | Always positive, steady current | Current drops to zero before next switching cycle |

| Efficiency | Higher efficiency at high load | Better efficiency at light load |

| Output Voltage Ripple | Lower ripple due to continuous inductor current | Higher ripple since current resets each cycle |

| Control Complexity | More complex control needed for stable operation | Relatively simpler control scheme |

| Inductor Size | Generally larger inductors required | Smaller inductors possible |

| EMI | Lower electromagnetic interference (EMI) | Higher EMI due to abrupt current changes |

| Applications | High-power systems, stable output voltage applications | Low-power, battery-powered applications |

Introduction to Boost Converters

Boost converters are power electronics devices designed to step up voltage from a lower to a higher level efficiently. Continuous Conduction Mode (CCM) boost converters maintain inductor current flow throughout the entire switching cycle, resulting in lower current ripple and improved efficiency in high-load applications. Discontinuous Conduction Mode (DCM) boost converters allow the inductor current to drop to zero during each cycle, enabling simpler control schemes and better performance at light loads or transient conditions.

Understanding CCM (Continuous Conduction Mode)

Continuous Conduction Mode (CCM) in boost converters occurs when the inductor current never falls to zero during the switching cycle, providing a steady and continuous energy transfer to the output. This mode improves efficiency and reduces current ripple, making it ideal for high-power applications and stable voltage regulation. In contrast to Discontinuous Conduction Mode (DCM), CCM supports better electromagnetic interference (EMI) performance and more predictable dynamic response.

Understanding DCM (Discontinuous Conduction Mode)

In a DCM (Discontinuous Conduction Mode) boost converter, the inductor current falls to zero during each switching cycle, creating intervals where no energy is transferred, which improves efficiency at light loads. Unlike CCM (Continuous Conduction Mode), where the inductor current never reaches zero, DCM operation reduces switching losses and electromagnetic interference, making it suitable for applications with variable or low power demands. Understanding DCM helps optimize your power supply design by balancing efficiency, stability, and size constraints in boost converter circuits.

Key Differences Between CCM and DCM

CCM (Continuous Conduction Mode) boost converters maintain current flow through the inductor at all times, resulting in lower current ripple and higher efficiency under steady loads. DCM (Discontinuous Conduction Mode) boost converters allow the inductor current to drop to zero during each switching cycle, which simplifies control and can reduce switching losses at light loads but increases current ripple. Your choice between CCM and DCM depends on load conditions, efficiency requirements, and design complexity, with CCM preferred for high power applications and DCM favored for light load scenarios.

Efficiency Comparison: CCM vs DCM

CCM boost converters generally offer higher efficiency at steady, moderate to high load currents due to continuous inductor current flow, reducing conduction losses. DCM boost converters can exhibit lower efficiency under similar conditions because of increased switching losses caused by current discontinuities, but they perform better at light loads by minimizing core losses and improving dynamic response. Your choice between CCM and DCM impacts efficiency depending on load conditions and switching frequency optimization.

Inductor Current Waveforms

CCM (Continuous Conduction Mode) boost converters maintain a continuous inductor current waveform, resulting in lower current ripple and improved efficiency compared to DCM (Discontinuous Conduction Mode). In DCM boost converters, the inductor current falls to zero during each switching cycle, causing higher current stress and increased electromagnetic interference. Your choice between CCM and DCM affects the inductor design, thermal performance, and overall converter stability based on the inductor current waveforms.

Design Considerations for CCM and DCM

Designing a Continuous Conduction Mode (CCM) boost converter requires ensuring the inductor current never falls to zero, which demands careful selection of inductance value and switching frequency to minimize current ripple and improve efficiency under higher load conditions. Discontinuous Conduction Mode (DCM) boost converter design prioritizes smaller inductors and simpler control schemes, as the inductor current resets to zero each cycle, making it suitable for light load applications but potentially causing higher peak currents and electromagnetic interference. Your choice between CCM and DCM affects switching losses, component stress, and overall converter performance, necessitating evaluation of load profile and efficiency targets in the design phase.

Application Suitability: CCM vs DCM

CCM (Continuous Conduction Mode) boost converters are ideal for applications requiring low output voltage ripple and high efficiency at medium to high load currents, such as in power supplies for industrial equipment and electric vehicles. DCM (Discontinuous Conduction Mode) boost converters suit low power applications where simpler circuit design and faster transient response are critical, commonly found in battery-powered devices and LED drivers. Your choice depends on whether consistent power delivery or simplified control and cost-efficiency are more important for your specific application.

Pros and Cons of CCM Boost Converters

CCM (Continuous Conduction Mode) boost converters offer improved efficiency and reduced output voltage ripple due to the inductor current never falling to zero, making them ideal for applications requiring stable power delivery and higher load currents. However, CCM designs tend to be more complex and may generate higher electromagnetic interference (EMI) compared to DCM (Discontinuous Conduction Mode) converters, which can complicate PCB layout and filtering requirements. Your choice between CCM and DCM boost converters will depend on specific needs for efficiency, load conditions, and noise considerations.

Pros and Cons of DCM Boost Converters

DCM (Discontinuous Conduction Mode) boost converters offer simpler control and reduced switching losses, making them suitable for low-power applications with fast transient response. However, they exhibit higher current ripple and electromagnetic interference (EMI) compared to CCM (Continuous Conduction Mode) converters, which can impact system efficiency and reliability. The inherently variable inductor current in DCM converters leads to more complex output voltage regulation under varying load conditions.

ccm boost converter vs dcm boost converter Infographic

electrown.com

electrown.com