Active clamp converters offer higher efficiency and better control of voltage stress on components compared to passive clamp converters, which rely on simpler, less costly components but suffer from increased losses and limited performance. To understand how your choice impacts power conversion efficiency and system reliability, delve deeper into the differences between these two converter types in the following article.

Table of Comparison

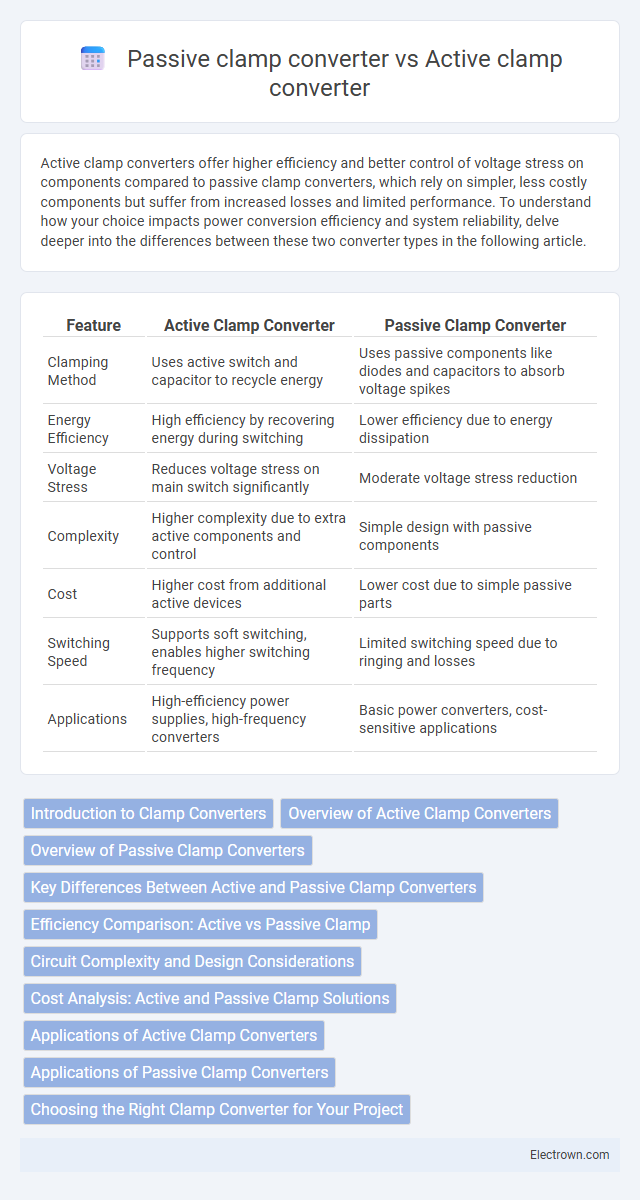

| Feature | Active Clamp Converter | Passive Clamp Converter |

|---|---|---|

| Clamping Method | Uses active switch and capacitor to recycle energy | Uses passive components like diodes and capacitors to absorb voltage spikes |

| Energy Efficiency | High efficiency by recovering energy during switching | Lower efficiency due to energy dissipation |

| Voltage Stress | Reduces voltage stress on main switch significantly | Moderate voltage stress reduction |

| Complexity | Higher complexity due to extra active components and control | Simple design with passive components |

| Cost | Higher cost from additional active devices | Lower cost due to simple passive parts |

| Switching Speed | Supports soft switching, enables higher switching frequency | Limited switching speed due to ringing and losses |

| Applications | High-efficiency power supplies, high-frequency converters | Basic power converters, cost-sensitive applications |

Introduction to Clamp Converters

Active clamp converters use semiconductor switches to recycle energy stored in the transformer leakage inductance, enhancing efficiency and reducing voltage stress on components. Passive clamp converters rely on passive components like diodes and capacitors to suppress voltage spikes, offering simpler design but lower efficiency. Your choice between active and passive clamp converters depends on the application's efficiency requirements and complexity tolerance.

Overview of Active Clamp Converters

Active clamp converters utilize an active switch and clamp circuit to recycle the energy stored in leakage inductance, significantly improving efficiency and reducing voltage stress on power devices compared to passive clamp converters. These converters enhance power density and thermal performance in applications such as DC-DC power supplies and LED drivers by minimizing switching losses and electromagnetic interference. Their ability to achieve zero-voltage switching (ZVS) contributes to higher reliability and extended device lifespan in high-frequency power conversion systems.

Overview of Passive Clamp Converters

Passive clamp converters utilize diodes and capacitors to absorb voltage spikes caused by transformer leakage inductance in switching power supplies, effectively protecting switches from high voltage stress. These converters offer a straightforward design with lower component count, resulting in reduced cost and complexity but often suffer from increased power dissipation and limited efficiency improvement. Passive clamp circuits are common in applications where cost sensitivity is critical and moderate efficiency is acceptable.

Key Differences Between Active and Passive Clamp Converters

Active clamp converters utilize semiconductor switches to recycle energy stored in the leakage inductance, significantly improving efficiency and reducing voltage stress on the main switch. Passive clamp converters rely on diodes and capacitors to clamp voltage spikes, resulting in simpler design but higher energy dissipation and increased power losses. The key differences lie in energy recovery capability, efficiency, complexity, and voltage stress management, with active clamps offering superior performance in high-frequency, high-power applications.

Efficiency Comparison: Active vs Passive Clamp

Active clamp converters generally achieve higher efficiency than passive clamp converters by reducing switching losses and improving energy recovery through controlled clamp circuits. Passive clamp converters tend to dissipate excess energy as heat through resistive elements, leading to lower overall efficiency. The enhanced efficiency in active clamp designs makes them preferable for high-performance power electronics requiring improved thermal management.

Circuit Complexity and Design Considerations

Active clamp converters feature more complex circuits with additional transistors and control components, enhancing efficiency and reducing voltage stress on the switches. Passive clamp converters utilize simpler components, such as diodes and capacitors, resulting in lower circuit complexity but less effective voltage clamping and higher switching losses. Your choice depends on balancing design complexity against efficiency and reliability requirements in your power conversion application.

Cost Analysis: Active and Passive Clamp Solutions

Active clamp converters typically incur higher initial costs due to their complex circuitry and additional components like MOSFETs and controllers, which enable improved efficiency and reduced stress on switches. Passive clamp converters offer a lower-cost alternative by using simple components such as diodes and resistors, but this simplicity often results in increased power loss and reduced overall efficiency. Cost analysis favors passive clamp solutions for budget-sensitive applications, while active clamp converters provide better long-term value through enhanced performance and reliability.

Applications of Active Clamp Converters

Active clamp converters are widely used in high-efficiency power supply designs for telecommunications, data centers, and electric vehicle charging systems due to their ability to recycle leakage energy and reduce voltage stress on switches. These converters enable higher switching frequencies, improving power density and thermal management compared to passive clamp converters. Their precise control and energy recovery capabilities make them ideal for applications demanding energy efficiency and reliability.

Applications of Passive Clamp Converters

Passive clamp converters are widely used in industrial power supplies and motor drive applications due to their simplicity and cost-effectiveness in energy recovery during switching transitions. These converters effectively protect switching devices by limiting voltage spikes and reducing electromagnetic interference, making them suitable for low- to medium-power systems. Your choice of a passive clamp converter enhances reliability in applications where high-frequency switching and moderate efficiency are acceptable.

Choosing the Right Clamp Converter for Your Project

Active clamp converters offer higher efficiency and reduced voltage stress on components, making them ideal for high-power and high-frequency applications. Passive clamp converters are simpler and cost-effective, suitable for low-power projects where system complexity and cost are primary concerns. Evaluating your project's power requirements and efficiency goals helps determine the optimal clamp converter choice.

Active clamp converter vs Passive clamp converter Infographic

electrown.com

electrown.com