DCM (Discontinuous Conduction Mode) and CCM (Continuous Conduction Mode) refer to operating states in power converters, where DCM features current falling to zero during part of the switching cycle, leading to lower efficiency but simpler control, while CCM maintains current flow throughout, improving efficiency and reducing output ripple. Understanding the key differences between DCM and CCM modes can help you optimize your power supply design; read on to explore their impacts on performance and application scenarios.

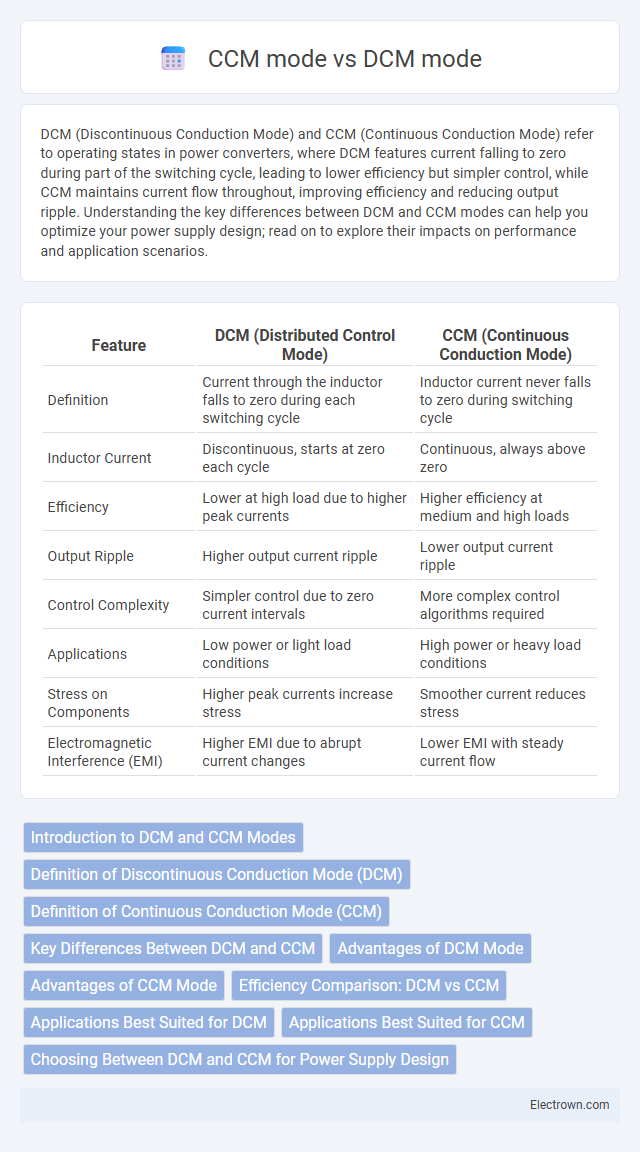

Table of Comparison

| Feature | DCM (Distributed Control Mode) | CCM (Continuous Conduction Mode) |

|---|---|---|

| Definition | Current through the inductor falls to zero during each switching cycle | Inductor current never falls to zero during switching cycle |

| Inductor Current | Discontinuous, starts at zero each cycle | Continuous, always above zero |

| Efficiency | Lower at high load due to higher peak currents | Higher efficiency at medium and high loads |

| Output Ripple | Higher output current ripple | Lower output current ripple |

| Control Complexity | Simpler control due to zero current intervals | More complex control algorithms required |

| Applications | Low power or light load conditions | High power or heavy load conditions |

| Stress on Components | Higher peak currents increase stress | Smoother current reduces stress |

| Electromagnetic Interference (EMI) | Higher EMI due to abrupt current changes | Lower EMI with steady current flow |

Introduction to DCM and CCM Modes

DCM (Discontinuous Conduction Mode) and CCM (Continuous Conduction Mode) are critical operating states in power converters and inductive circuits. In DCM, the current through the inductor falls to zero during each switching cycle, which can improve efficiency at light loads but increases ripple and complexity. CCM maintains a continuous current flow, providing stable output and reduced electromagnetic interference, making it ideal for higher power applications, and understanding these modes helps optimize your system's performance.

Definition of Discontinuous Conduction Mode (DCM)

Discontinuous Conduction Mode (DCM) occurs when the current through an inductor in a power converter falls to zero during part of the switching cycle, resulting in intervals where no energy is transferred to the load. This mode is typical in low-load or light-load conditions, causing reduced core losses but increased peak currents and voltage stress. DCM contrasts with Continuous Conduction Mode (CCM), where the inductor current never reaches zero throughout the entire switching cycle.

Definition of Continuous Conduction Mode (CCM)

Continuous Conduction Mode (CCM) occurs when the current through an inductor never falls to zero during the entire switching cycle in power electronics converters. In CCM, the inductor current remains continuous, ensuring stable voltage output and reduced ripple compared to Discontinuous Conduction Mode (DCM). Your power supply performance benefits from improved efficiency and predictable inductor behavior under CCM conditions.

Key Differences Between DCM and CCM

DCM (Discontinuous Conduction Mode) occurs when the inductor current falls to zero during part of the switching cycle, leading to lower average current and reduced switching losses. CCM (Continuous Conduction Mode) maintains inductor current above zero throughout the cycle, ensuring steady energy transfer and improved efficiency under higher load conditions. DCM typically results in a simpler control strategy but higher peak currents, whereas CCM offers stable operation and lower peak currents with more complex control requirements.

Advantages of DCM Mode

DCM mode offers improved energy efficiency by reducing switching losses and minimizing conduction losses during light load conditions. This mode enhances electromagnetic interference (EMI) performance due to zero current switching transitions, leading to quieter operation. The inherent ability of DCM mode to naturally limit current increases system reliability and simplifies control circuit design.

Advantages of CCM Mode

CCM mode offers authenticated encryption, combining confidentiality and integrity in a single, efficient process that prevents tampering and ensures data authenticity. Its design provides robustness against a wide range of cryptographic attacks, making it suitable for secure communications in sensitive applications such as IoT and wireless networks. Performance optimizations in hardware and software implementations enhance CCM's efficiency, especially in environments with constrained resources.

Efficiency Comparison: DCM vs CCM

Discontinuous Conduction Mode (DCM) typically offers higher efficiency at light loads due to reduced switching losses, while Continuous Conduction Mode (CCM) excels at higher loads by minimizing conduction losses through continuous current flow. In CCM, the inductor current never falls to zero, resulting in lower peak currents and reduced core losses, which enhances efficiency in moderate to heavy load conditions. Efficiency curves of converters show that CCM outperforms DCM above a certain load threshold, making mode selection critical for optimizing power conversion efficiency in specific applications.

Applications Best Suited for DCM

DCM (Discontinuous Conduction Mode) is best suited for applications requiring high efficiency at light loads, such as battery chargers, LED drivers, and low-power DC-DC converters. Its operation reduces switching losses and electromagnetic interference, making it ideal for portable devices and energy-saving power supplies. DCM is also preferred in isolated power supplies where simplified control and fast transient response are critical.

Applications Best Suited for CCM

CCM (Continuous Conduction Mode) is best suited for applications requiring stable and low-ripple current, such as regulated power supplies, LED drivers, and electric vehicle chargers. This mode ensures continuous energy transfer through inductors, minimizing output voltage fluctuations and improving efficiency at moderate to high loads. CCM is preferred in scenarios demanding precise control and reduced electromagnetic interference compared to DCM (Discontinuous Conduction Mode).

Choosing Between DCM and CCM for Power Supply Design

Choosing between Discontinuous Conduction Mode (DCM) and Continuous Conduction Mode (CCM) in power supply design depends on factors like load conditions, efficiency requirements, and electromagnetic interference (EMI) constraints. CCM is preferred for higher power applications demanding lower output ripple and improved efficiency under continuous load, while DCM suits lighter loads with simpler control and reduced magnetic component size. Optimizing for transient response and thermal performance ensures the selected mode meets specific design goals.

dcm vs ccm mode Infographic

electrown.com

electrown.com