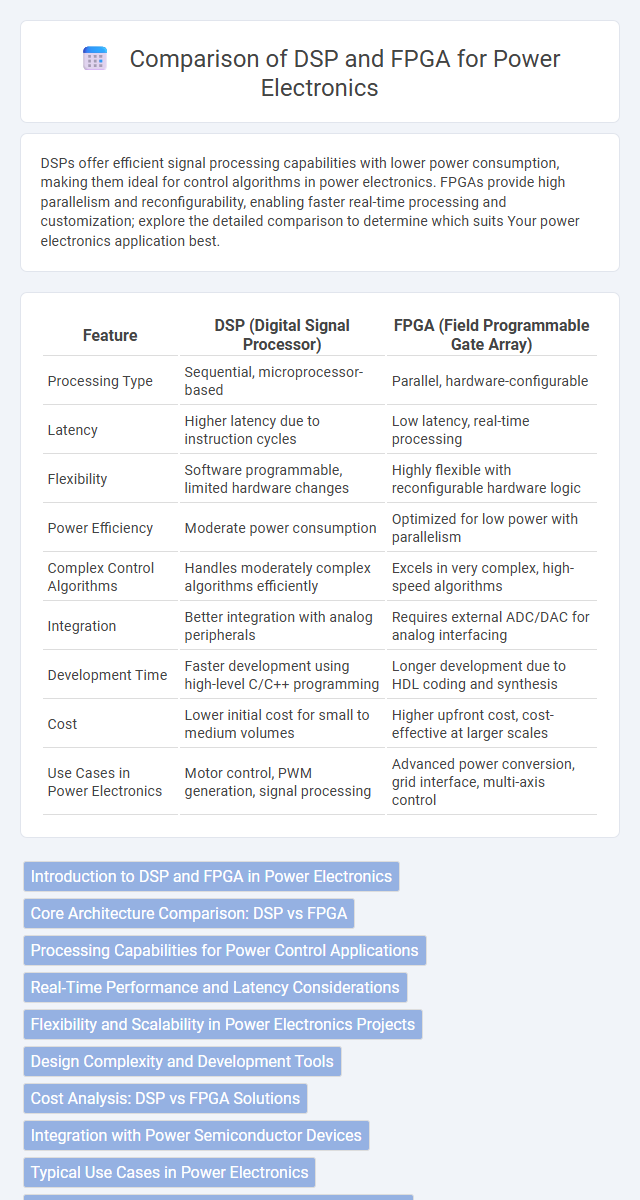

DSPs offer efficient signal processing capabilities with lower power consumption, making them ideal for control algorithms in power electronics. FPGAs provide high parallelism and reconfigurability, enabling faster real-time processing and customization; explore the detailed comparison to determine which suits Your power electronics application best.

Table of Comparison

| Feature | DSP (Digital Signal Processor) | FPGA (Field Programmable Gate Array) |

|---|---|---|

| Processing Type | Sequential, microprocessor-based | Parallel, hardware-configurable |

| Latency | Higher latency due to instruction cycles | Low latency, real-time processing |

| Flexibility | Software programmable, limited hardware changes | Highly flexible with reconfigurable hardware logic |

| Power Efficiency | Moderate power consumption | Optimized for low power with parallelism |

| Complex Control Algorithms | Handles moderately complex algorithms efficiently | Excels in very complex, high-speed algorithms |

| Integration | Better integration with analog peripherals | Requires external ADC/DAC for analog interfacing |

| Development Time | Faster development using high-level C/C++ programming | Longer development due to HDL coding and synthesis |

| Cost | Lower initial cost for small to medium volumes | Higher upfront cost, cost-effective at larger scales |

| Use Cases in Power Electronics | Motor control, PWM generation, signal processing | Advanced power conversion, grid interface, multi-axis control |

Introduction to DSP and FPGA in Power Electronics

Digital Signal Processors (DSPs) and Field-Programmable Gate Arrays (FPGAs) play critical roles in power electronics by enabling precise control and efficient processing of power conversion signals. DSPs offer high-level programmability and real-time signal processing capabilities optimal for complex algorithms in power system control, while FPGAs provide parallel processing and customizable hardware acceleration to handle high-speed switching and intricate timing requirements. Your choice between DSP and FPGA depends on application-specific demands such as latency, flexibility, and computational complexity in power electronics.

Core Architecture Comparison: DSP vs FPGA

DSP core architecture is based on specialized single or multiple processing units optimized for arithmetic operations like multiply-accumulate, enabling efficient real-time signal processing in power electronics. FPGA architecture consists of configurable logic blocks and interconnects that allow parallel hardware implementation of control algorithms, providing high flexibility and low latency for power conversion tasks. While DSPs excel in algorithmic complexity with sequential processing, FPGAs offer customizable, concurrent execution, crucial for precise timing and dynamic control in power electronics applications.

Processing Capabilities for Power Control Applications

DSPs offer high-speed arithmetic operations tailored for real-time signal processing in power control applications, enabling efficient execution of complex algorithms like PWM and harmonic analysis. FPGAs provide parallel processing capabilities and customizable hardware architecture, allowing for lower latency and greater flexibility in implementing advanced power management functions. Your choice depends on the need for rapid numerical computations (DSP) versus hardware-level parallelism and configurability (FPGA) in power electronics control.

Real-Time Performance and Latency Considerations

DSPs offer efficient real-time performance with low latency, ideal for control algorithms requiring precise timing in power electronics applications. FPGAs provide parallel processing capabilities that further reduce latency by executing multiple operations simultaneously, enhancing responsiveness in complex power converter systems. Your choice depends on the specific latency requirements and computational complexity of the control tasks.

Flexibility and Scalability in Power Electronics Projects

Digital Signal Processors (DSPs) offer high-speed computation and are optimized for real-time control in power electronics, providing moderate flexibility for algorithm updates but limited scalability for complex system expansions. Field-Programmable Gate Arrays (FPGAs) deliver unparalleled flexibility through hardware reconfigurability, enabling custom parallel processing architectures that significantly enhance scalability in power electronics projects. This adaptability makes FPGAs ideal for evolving applications requiring precise control and integration of multiple power modules.

Design Complexity and Development Tools

DSPs offer streamlined design complexity with high-level programming languages like C/C++ and extensive software libraries tailored for power electronics control algorithms. FPGAs require intricate hardware description languages (HDLs) such as VHDL or Verilog, demanding deeper expertise in digital design and parallel processing architectures. Development tools for DSPs include comprehensive IDEs and real-time debugging support, whereas FPGA tools focus on synthesis, simulation, and timing analysis, increasing the initial development effort but enabling highly customized and parallel implementations.

Cost Analysis: DSP vs FPGA Solutions

DSP solutions typically offer lower initial costs due to simpler architecture and widespread availability, making them cost-effective for standard power electronics applications. FPGAs, while generally more expensive upfront, provide flexibility and parallel processing capabilities that can reduce system-level costs in complex or customized power electronics designs. Your choice should consider not only component prices but also development time, scalability, and long-term maintenance expenses.

Integration with Power Semiconductor Devices

Digital Signal Processors (DSPs) offer streamlined integration with power semiconductor devices through built-in analog-to-digital converters and tailored control peripherals, facilitating precise real-time monitoring and control in power electronics. Field-Programmable Gate Arrays (FPGAs) provide highly customizable hardware parallelism that enables synchronous control of multiple power semiconductor switches with ultra-low latency, making them ideal for complex modulation and protection schemes. The choice between DSP and FPGA hinges on the specific integration requirements, balancing ease of use and flexibility against performance and latency demands in power device control.

Typical Use Cases in Power Electronics

Digital Signal Processors (DSPs) are commonly used in power electronics for real-time control applications such as motor drives, power factor correction, and renewable energy systems due to their efficient handling of complex mathematical algorithms. Field-Programmable Gate Arrays (FPGAs) excel in implementing parallel processing tasks and custom hardware acceleration, making them ideal for high-frequency switching control and fast response in power converters and grid-tied inverters. Both DSPs and FPGAs contribute significantly to enhancing the efficiency, precision, and reliability of modern power electronic systems.

Future Trends in Digital Control for Power Electronics

Future trends in digital control for power electronics emphasize the growing integration of DSPs and FPGAs to optimize system performance and flexibility. FPGAs offer customizable parallel processing capabilities ideal for real-time control and fast switching applications, while DSPs excel in complex algorithm execution and signal processing with lower development effort. Your choice between FPGA and DSP will increasingly depend on balancing speed, power efficiency, and adaptability to advanced control techniques like AI-based predictive maintenance and adaptive modulation schemes.

DSP vs FPGA for power electronics Infographic

electrown.com

electrown.com