Coreless transformers eliminate the traditional magnetic core, reducing eddy current losses and allowing for higher frequency operation with improved efficiency, while ferrite transformers use a magnetic core made of ferrite material to enhance magnetic flux and energy transfer in lower-frequency ranges. Discover how choosing between coreless and ferrite transformers can impact Your electronic designs by exploring the detailed comparison in this article.

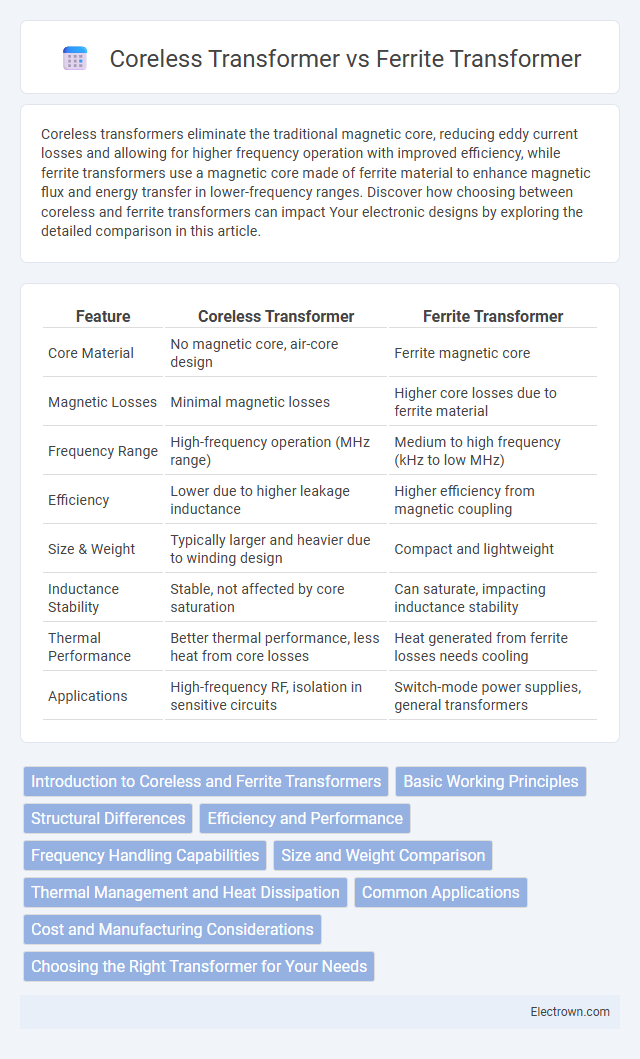

Table of Comparison

| Feature | Coreless Transformer | Ferrite Transformer |

|---|---|---|

| Core Material | No magnetic core, air-core design | Ferrite magnetic core |

| Magnetic Losses | Minimal magnetic losses | Higher core losses due to ferrite material |

| Frequency Range | High-frequency operation (MHz range) | Medium to high frequency (kHz to low MHz) |

| Efficiency | Lower due to higher leakage inductance | Higher efficiency from magnetic coupling |

| Size & Weight | Typically larger and heavier due to winding design | Compact and lightweight |

| Inductance Stability | Stable, not affected by core saturation | Can saturate, impacting inductance stability |

| Thermal Performance | Better thermal performance, less heat from core losses | Heat generated from ferrite losses needs cooling |

| Applications | High-frequency RF, isolation in sensitive circuits | Switch-mode power supplies, general transformers |

Introduction to Coreless and Ferrite Transformers

Coreless transformers, which lack a magnetic core, use air as the magnetic medium, resulting in lower eddy current losses and improved high-frequency performance compared to ferrite transformers. Ferrite transformers incorporate ferrite cores made from ceramic compounds that provide high magnetic permeability, enhancing energy transfer efficiency and reducing core losses in power applications. Understanding the differences between your coreless and ferrite transformer options helps optimize performance based on frequency, size, and efficiency requirements.

Basic Working Principles

Coreless transformers rely on air or non-magnetic materials as the magnetic circuit, utilizing tightly wound coils to transfer energy through electromagnetic induction with minimal core losses. Ferrite transformers employ a ferrite core made of iron oxide and ceramic compounds to concentrate the magnetic flux, enhancing coupling efficiency and reducing leakage inductance. The difference in magnetic path design significantly influences efficiency, frequency response, and thermal performance in power conversion applications.

Structural Differences

Coreless transformers eliminate the traditional magnetic core, relying on air or other non-magnetic materials for magnetic flux, which reduces core losses and electromagnetic interference. Ferrite transformers incorporate a ferrite core made of iron oxide mixed with other metals, enhancing magnetic permeability and improving energy efficiency by concentrating the magnetic field. Your choice depends on application needs, as coreless designs offer flexibility and high-frequency performance, whereas ferrite transformers provide robust magnetic coupling and efficiency in lower frequency ranges.

Efficiency and Performance

Coreless transformers exhibit higher efficiency in high-frequency applications due to the absence of core losses like hysteresis and eddy currents, which are inherent in ferrite transformers. Ferrite transformers provide better magnetic flux containment and are generally more efficient at lower frequencies, offering stable performance in power conversion. The choice between coreless and ferrite transformers hinges on operational frequency and efficiency requirements, with coreless models excelling in lightweight, high-frequency scenarios while ferrite transformers dominate in conventional power applications.

Frequency Handling Capabilities

Coreless transformers excel in high-frequency handling due to the absence of magnetic core losses, making them ideal for applications above several MHz. Ferrite transformers, with magnetic cores made from ferrite materials, perform efficiently in a wide frequency range typically from tens of kHz to a few MHz but may experience core losses at very high frequencies. Your choice between coreless and ferrite transformers should consider the specific frequency requirements and efficiency needs of your application.

Size and Weight Comparison

Coreless transformers are significantly lighter and more compact than ferrite transformers due to the absence of a magnetic core, which reduces material usage and overall bulk. Ferrite transformers rely on a solid ferrite core to achieve efficient magnetic flux coupling, resulting in increased size and weight compared to coreless designs. The reduced mass and volume of coreless transformers make them ideal for applications where space and weight constraints are critical.

Thermal Management and Heat Dissipation

Coreless transformers exhibit superior thermal management due to the absence of a magnetic core, which eliminates core losses and significantly reduces heat generation during operation. Ferrite transformers, while efficient in magnetic flux handling, produce heat through core hysteresis and eddy current losses, necessitating robust heat dissipation mechanisms such as heat sinks or forced cooling. Enhanced thermal conductivity in coreless designs promotes uniform temperature distribution, improving reliability and lifespan compared to ferrite transformers prone to localized hot spots.

Common Applications

Coreless transformers are ideal for high-frequency applications such as wireless power transfer, medical devices, and precision instrumentation due to their low core losses and reduced electromagnetic interference. Ferrite transformers are commonly used in power supplies, audio equipment, and switching devices where efficient energy transfer and magnetic flux concentration are crucial. Your choice depends on the specific application requirements, such as frequency range and efficiency needs.

Cost and Manufacturing Considerations

Coreless transformers typically have higher manufacturing costs due to the need for specialized winding techniques and the absence of a magnetic core that facilitates flux concentration. Ferrite transformers benefit from lower material costs as ferrite cores are inexpensive and widely available, simplifying production and enabling mass manufacturing. The manufacturing process for ferrite transformers is more straightforward, resulting in reduced labor and equipment expenses compared to the intricate assembly requirements of coreless transformers.

Choosing the Right Transformer for Your Needs

Choosing between a coreless transformer and a ferrite transformer depends on efficiency, frequency, and application size. Coreless transformers excel in high-frequency applications with minimal core losses, making them ideal for compact, lightweight devices. Ferrite transformers, featuring a magnetic core, provide higher power handling and better efficiency at lower frequencies, often used in power supplies and industrial equipment.

Coreless transformer vs Ferrite transformer Infographic

electrown.com

electrown.com