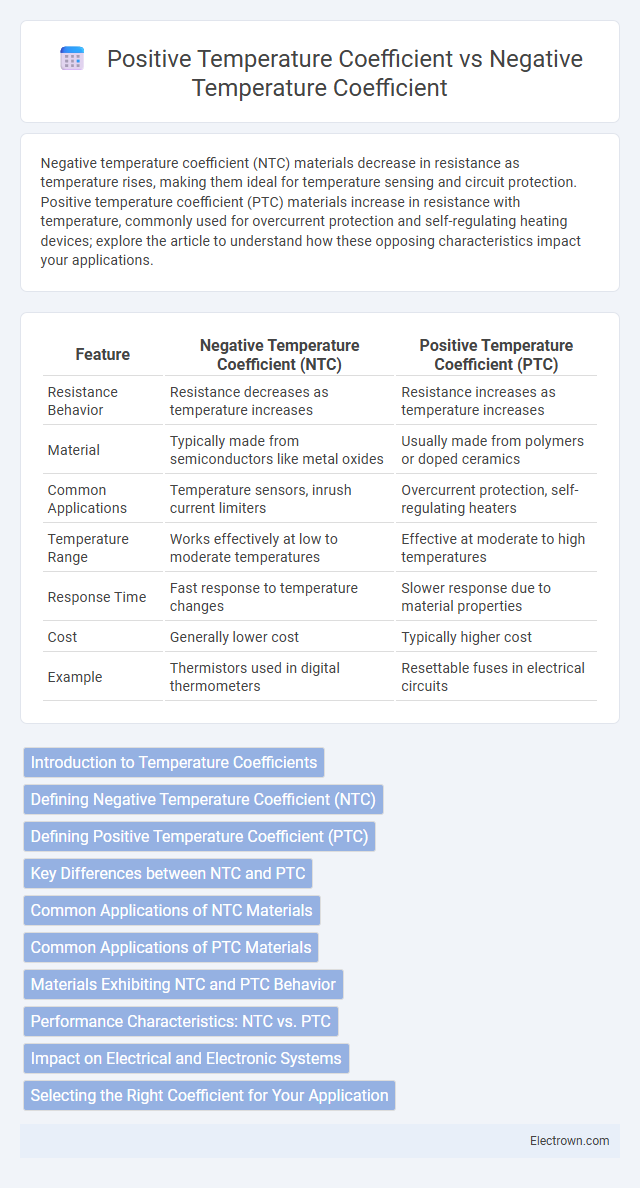

Negative temperature coefficient (NTC) materials decrease in resistance as temperature rises, making them ideal for temperature sensing and circuit protection. Positive temperature coefficient (PTC) materials increase in resistance with temperature, commonly used for overcurrent protection and self-regulating heating devices; explore the article to understand how these opposing characteristics impact your applications.

Table of Comparison

| Feature | Negative Temperature Coefficient (NTC) | Positive Temperature Coefficient (PTC) |

|---|---|---|

| Resistance Behavior | Resistance decreases as temperature increases | Resistance increases as temperature increases |

| Material | Typically made from semiconductors like metal oxides | Usually made from polymers or doped ceramics |

| Common Applications | Temperature sensors, inrush current limiters | Overcurrent protection, self-regulating heaters |

| Temperature Range | Works effectively at low to moderate temperatures | Effective at moderate to high temperatures |

| Response Time | Fast response to temperature changes | Slower response due to material properties |

| Cost | Generally lower cost | Typically higher cost |

| Example | Thermistors used in digital thermometers | Resettable fuses in electrical circuits |

Introduction to Temperature Coefficients

Temperature coefficients describe how a material's electrical resistance changes with temperature. Negative Temperature Coefficient (NTC) materials decrease resistance as temperature rises, making them ideal for temperature sensing and inrush current limiting. Positive Temperature Coefficient (PTC) materials increase resistance with temperature, providing self-regulating heating and overcurrent protection, allowing your devices to operate safely under varying thermal conditions.

Defining Negative Temperature Coefficient (NTC)

Negative Temperature Coefficient (NTC) refers to materials or devices whose resistance decreases as temperature increases, making them ideal for temperature sensing and protection circuits. Commonly used NTC thermistors exhibit highly predictable resistance changes, enabling precise temperature measurements in applications like HVAC systems and battery management. Your choice between NTC and Positive Temperature Coefficient (PTC) components depends on whether you require decreasing or increasing resistance with temperature rise.

Defining Positive Temperature Coefficient (PTC)

Positive Temperature Coefficient (PTC) refers to materials or devices whose electrical resistance increases as the temperature rises, making them valuable for applications such as self-regulating heaters and current limiters. Unlike Negative Temperature Coefficient (NTC) thermistors, which decrease resistance with temperature, PTC thermistors help protect circuits by limiting current flow during temperature spikes. Your choice between PTC and NTC devices depends on the specific thermal management and safety requirements of your application.

Key Differences between NTC and PTC

Negative temperature coefficient (NTC) thermistors decrease resistance as temperature rises, making them ideal for temperature sensing and inrush current limiting. Positive temperature coefficient (PTC) thermistors increase resistance with temperature, commonly used for overcurrent protection and self-regulating heating elements. Your choice between NTC and PTC depends on whether you need a device that responds by lowering or raising resistance with temperature changes.

Common Applications of NTC Materials

Negative Temperature Coefficient (NTC) materials are predominantly used in temperature sensing and inrush current limiting applications due to their resistance decreasing as temperature rises. Common applications include thermistors for precise temperature measurement in HVAC systems, automotive engine sensors, and rechargeable battery management. NTC thermistors also protect electronic circuits by limiting inrush currents during power-up in devices like power supplies and motor controls.

Common Applications of PTC Materials

PTC materials are commonly used in overcurrent protectors and self-regulating heating elements due to their ability to increase resistance as temperature rises. Positive temperature coefficient thermistors are frequently found in circuit protection devices like resettable fuses and temperature sensors. In contrast, NTC materials are typically applied in inrush current limiters and temperature measurement instruments where resistance decreases with rising temperature.

Materials Exhibiting NTC and PTC Behavior

Materials exhibiting negative temperature coefficient (NTC) behavior typically include semiconductor ceramics such as manganese oxide, nickel oxide, and cobalt oxide, which decrease in resistance as temperature rises. In contrast, positive temperature coefficient (PTC) materials often consist of barium titanate-based ceramics and certain polymers that increase in resistance with temperature elevation. Understanding these material properties can help you select the appropriate thermistor type for temperature sensing or circuit protection applications.

Performance Characteristics: NTC vs. PTC

Negative Temperature Coefficient (NTC) thermistors decrease in resistance as temperature rises, making them highly sensitive for precise temperature measurements and rapid response applications. Positive Temperature Coefficient (PTC) thermistors increase in resistance with temperature, providing self-regulating heating and overcurrent protection due to their ability to limit current flow at higher temperatures. Your choice between NTC and PTC components depends on whether you need accurate temperature sensing or reliable current limiting performance.

Impact on Electrical and Electronic Systems

Negative temperature coefficient (NTC) thermistors decrease resistance as temperature rises, which helps in protecting circuits by limiting inrush current and providing temperature sensing for thermal management in electrical and electronic systems. Positive temperature coefficient (PTC) thermistors increase resistance with temperature, offering self-regulating heating elements or acting as resettable fuses to prevent overheating and damage. Understanding your system's requirements for current control or overtemperature protection determines whether an NTC or PTC component will optimize performance and reliability.

Selecting the Right Coefficient for Your Application

Choosing between a Negative Temperature Coefficient (NTC) and Positive Temperature Coefficient (PTC) thermistor depends on your application's specific temperature response needs. NTC thermistors decrease resistance as temperature rises, making them ideal for accurate temperature sensing and inrush current limiting. PTC thermistors increase resistance with temperature, providing reliable overcurrent protection and self-regulating heating functions in your circuits.

Negative temperature coefficient vs Positive temperature coefficient Infographic

electrown.com

electrown.com