Planar transformers offer enhanced efficiency and thermal management compared to traditional transformers due to their compact, layered design that allows better heat dissipation and reduced electromagnetic interference. Explore the rest of the article to understand how these differences can impact your next electronics project or power supply design.

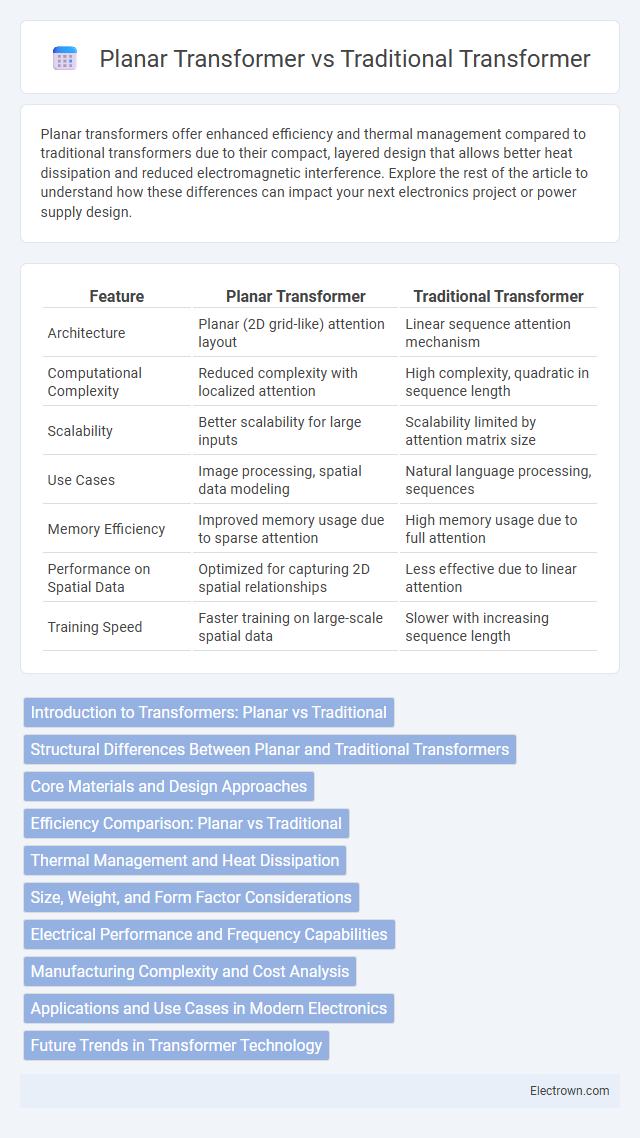

Table of Comparison

| Feature | Planar Transformer | Traditional Transformer |

|---|---|---|

| Architecture | Planar (2D grid-like) attention layout | Linear sequence attention mechanism |

| Computational Complexity | Reduced complexity with localized attention | High complexity, quadratic in sequence length |

| Scalability | Better scalability for large inputs | Scalability limited by attention matrix size |

| Use Cases | Image processing, spatial data modeling | Natural language processing, sequences |

| Memory Efficiency | Improved memory usage due to sparse attention | High memory usage due to full attention |

| Performance on Spatial Data | Optimized for capturing 2D spatial relationships | Less effective due to linear attention |

| Training Speed | Faster training on large-scale spatial data | Slower with increasing sequence length |

Introduction to Transformers: Planar vs Traditional

Planar transformers feature a compact, layered design with printed circuit board (PCB) windings, offering improved efficiency and heat dissipation compared to traditional transformers that use wire-wound coils around magnetic cores. Their low profile and precise manufacturing make planar transformers ideal for high-frequency applications, while traditional transformers excel in handling high power at lower frequencies. Your choice depends on the application's size constraints, thermal management needs, and frequency requirements.

Structural Differences Between Planar and Traditional Transformers

Planar transformers feature flat, layered windings fabricated on thin copper or metal layers, contrasting with the bulky coil windings of traditional transformers. Their compact, PCB-compatible structure enables efficient heat dissipation and reduced parasitic inductance. Your choice between the two impacts the overall size, thermal management, and electrical performance of power electronics designs.

Core Materials and Design Approaches

Planar transformers utilize thin, laminated ferrite or nanocrystalline cores designed for high-frequency applications, enabling compact and efficient magnetic flux paths. Traditional transformers commonly employ laminated silicon steel cores optimized for lower frequencies, resulting in bulkier and heavier structures. Your choice between planar and traditional transformers should consider the core material's magnetic properties and design approach to achieve desired efficiency and size constraints.

Efficiency Comparison: Planar vs Traditional

Planar transformers offer higher efficiency than traditional transformers due to lower parasitic inductance and capacitance, which reduces energy losses during power conversion. Their compact design allows for better thermal management, enhancing overall performance and reliability. If you seek optimized energy usage and space-saving solutions, planar transformers provide a more efficient alternative to conventional transformer designs.

Thermal Management and Heat Dissipation

Planar transformers exhibit superior thermal management compared to traditional transformers due to their low-profile design and enhanced surface area for heat dissipation. The integration of planar windings on flat PCB substrates allows for efficient heat transfer and reduced hot spots, improving overall reliability and performance. Your application benefits from reduced thermal stress and longer component lifespan when selecting planar transformers for high-frequency power conversion.

Size, Weight, and Form Factor Considerations

Planar transformers offer a significant reduction in size and weight compared to traditional transformers due to their compact, flat winding structure. Their optimized form factor allows for better thermal management and integration into space-constrained electronic devices. When designing for efficiency and miniaturization, your choice of planar transformers can lead to more streamlined and lightweight power solutions.

Electrical Performance and Frequency Capabilities

Planar transformers offer superior electrical performance with lower leakage inductance and reduced parasitic capacitance, enhancing signal integrity and efficiency. They excel in high-frequency applications, typically operating efficiently above 100 kHz, unlike traditional transformers which are limited by bulky, wound wire designs and higher eddy current losses. Choosing a planar transformer can improve your power conversion system's performance and frequency response, especially in compact, high-speed electronics.

Manufacturing Complexity and Cost Analysis

Planar transformers feature a printed circuit board (PCB) winding design that significantly reduces manufacturing complexity compared to traditional wire-wound transformers, enabling automated assembly and improved repeatability. The PCB-based construction lowers labor costs and minimizes material waste, resulting in lower overall production costs. Traditional transformers require more manual labor and precise winding processes, which often increase manufacturing time and expenses, especially in high-volume production.

Applications and Use Cases in Modern Electronics

Planar transformers are widely used in high-frequency applications such as power supplies for data centers, telecommunications, and electric vehicles due to their compact size, superior thermal management, and low electromagnetic interference. Traditional transformers remain prevalent in low-frequency, high-power applications like industrial machinery, audio equipment, and power distribution where robustness and cost-effectiveness are critical. Your choice between planar and traditional transformers depends on the specific requirements of efficiency, space constraints, and frequency range in modern electronics.

Future Trends in Transformer Technology

Planar transformers offer significant advantages over traditional transformers by providing higher efficiency, better thermal management, and more compact form factors, making them ideal for future high-frequency power conversion applications. Innovations in semiconductor materials and manufacturing processes are expected to drive widespread adoption of planar technology in electric vehicles, renewable energy systems, and data centers. Your choice of transformer technology will benefit from these ongoing advancements, enabling more reliable and energy-efficient power solutions.

planar transformer vs traditional transformer Infographic

electrown.com

electrown.com