PWM control provides precise modulation of power by adjusting the duty cycle of the signal, ensuring efficient energy use and stable output voltage. Understanding the differences between PWM control and hysteresis control can help you choose the optimal method for your specific application--continue reading to explore their advantages and use cases.

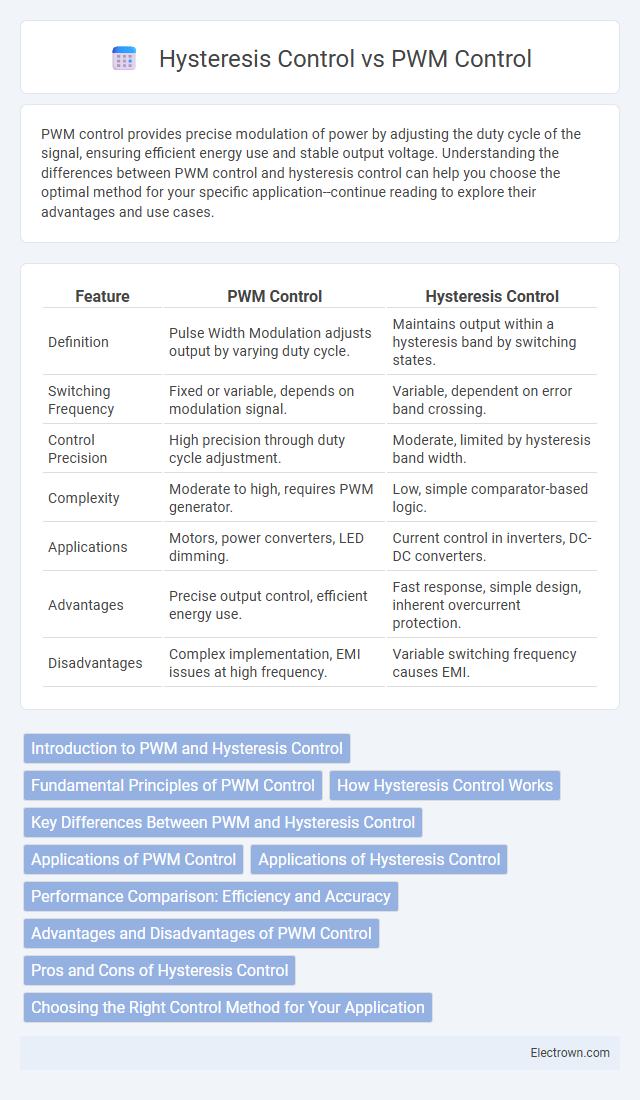

Table of Comparison

| Feature | PWM Control | Hysteresis Control |

|---|---|---|

| Definition | Pulse Width Modulation adjusts output by varying duty cycle. | Maintains output within a hysteresis band by switching states. |

| Switching Frequency | Fixed or variable, depends on modulation signal. | Variable, dependent on error band crossing. |

| Control Precision | High precision through duty cycle adjustment. | Moderate, limited by hysteresis band width. |

| Complexity | Moderate to high, requires PWM generator. | Low, simple comparator-based logic. |

| Applications | Motors, power converters, LED dimming. | Current control in inverters, DC-DC converters. |

| Advantages | Precise output control, efficient energy use. | Fast response, simple design, inherent overcurrent protection. |

| Disadvantages | Complex implementation, EMI issues at high frequency. | Variable switching frequency causes EMI. |

Introduction to PWM and Hysteresis Control

Pulse Width Modulation (PWM) control adjusts the duty cycle of a signal to regulate power delivery with precision, offering smooth and efficient control in various applications like motor drives and power converters. Hysteresis control maintains the output within a predefined tolerance band by switching the device on and off when the output reaches upper or lower thresholds, providing rapid response and simplicity. Understanding the distinctions between these methods helps you choose the most effective control strategy based on system dynamics and performance requirements.

Fundamental Principles of PWM Control

PWM control operates by modulating pulse width to regulate power delivery, maintaining a constant switching frequency while adjusting the duty cycle to control output voltage or current. This method uses a timer or oscillator to generate fixed-frequency pulses, where the on-time varies proportionally to the desired output level. The primary advantage of PWM control lies in its predictable frequency, which simplifies filtering and reduces electromagnetic interference (EMI) compared to hysteresis control, which varies switching frequency based on error band thresholds.

How Hysteresis Control Works

Hysteresis control operates by maintaining a variable within a predefined band around the reference value, switching the output on or off to keep the parameter within these upper and lower limits. This control method responds rapidly to changes, offering precise and robust performance in current regulation applications like motor drives or power converters. Your system benefits from hysteresis control's simplicity and reduced computational requirements compared to PWM control, ensuring efficient and stable operation under varying load conditions.

Key Differences Between PWM and Hysteresis Control

PWM control regulates power delivery by varying pulse width at fixed frequency, enabling precise output voltage and current control with lower switching losses. Hysteresis control maintains output within a defined error band using variable switching frequency, resulting in fast response yet higher electromagnetic interference due to rapid switching. Key differences include PWM's fixed switching frequency versus hysteresis control's variable frequency, trade-offs between efficiency and dynamic response, and their suitability for applications requiring steady-state accuracy versus quick transient response.

Applications of PWM Control

PWM control is widely used in applications requiring precise voltage regulation and efficient power conversion, including motor drives, LED dimming, and power supplies. Its ability to maintain consistent output voltage and reduce power loss makes it ideal for renewable energy systems such as solar inverters and battery chargers. You can leverage PWM control for improved energy efficiency and fine-tuned speed control in electric vehicles and industrial automation.

Applications of Hysteresis Control

Hysteresis control is widely applied in power electronics for motor drives, inverters, and DC-DC converters due to its fast response and robustness against parameter variations. It is particularly effective in applications requiring precise current control and low switching losses, such as brushless DC motors and induction motor drives. This method ensures stable operation in systems with varying load conditions and high-frequency disturbance rejection.

Performance Comparison: Efficiency and Accuracy

PWM control offers higher efficiency by maintaining a constant switching frequency, which reduces power losses and electromagnetic interference, making it ideal for applications requiring precise energy management. Hysteresis control provides superior accuracy in current regulation due to its real-time feedback mechanism, but this comes at the expense of variable switching frequency and increased switching losses. Your choice between these methods should balance the need for efficiency versus the demand for precise control in dynamic load conditions.

Advantages and Disadvantages of PWM Control

PWM control offers precise adjustment of motor speed and torque by varying the duty cycle of the switching signal, ensuring high efficiency and reduced power loss. It enables smoother operation and better thermal management but can introduce electromagnetic interference (EMI) issues requiring effective filtering solutions. The complexity of implementation and increased switching frequency may lead to higher system costs compared to simpler control methods like hysteresis control.

Pros and Cons of Hysteresis Control

Hysteresis control offers fast dynamic response and robustness against parameter variations, making it ideal for applications requiring precise current regulation. However, it suffers from variable switching frequency, which can lead to electromagnetic interference and complicate filter design. Your choice depends on whether you prioritize simplicity and responsiveness (hysteresis) or fixed switching frequency and smoother operation (PWM).

Choosing the Right Control Method for Your Application

PWM control offers precise output voltage regulation with high switching frequency, making it ideal for applications requiring energy efficiency and low electromagnetic interference. Hysteresis control provides fast dynamic response and robustness against parameter variations, suitable for systems where rapid current adjustment and simplicity are critical. Selecting between PWM and hysteresis control depends on factors like desired response speed, system complexity, and electromagnetic compatibility requirements.

pwm control vs hysteresis control Infographic

electrown.com

electrown.com