PWM rectifiers offer superior power quality with reduced harmonic distortion and improved efficiency compared to thyristor rectifiers, which are simpler but generate more harmonics and have lower power factor. Explore the rest of the article to understand which rectifier best suits your specific application and performance requirements.

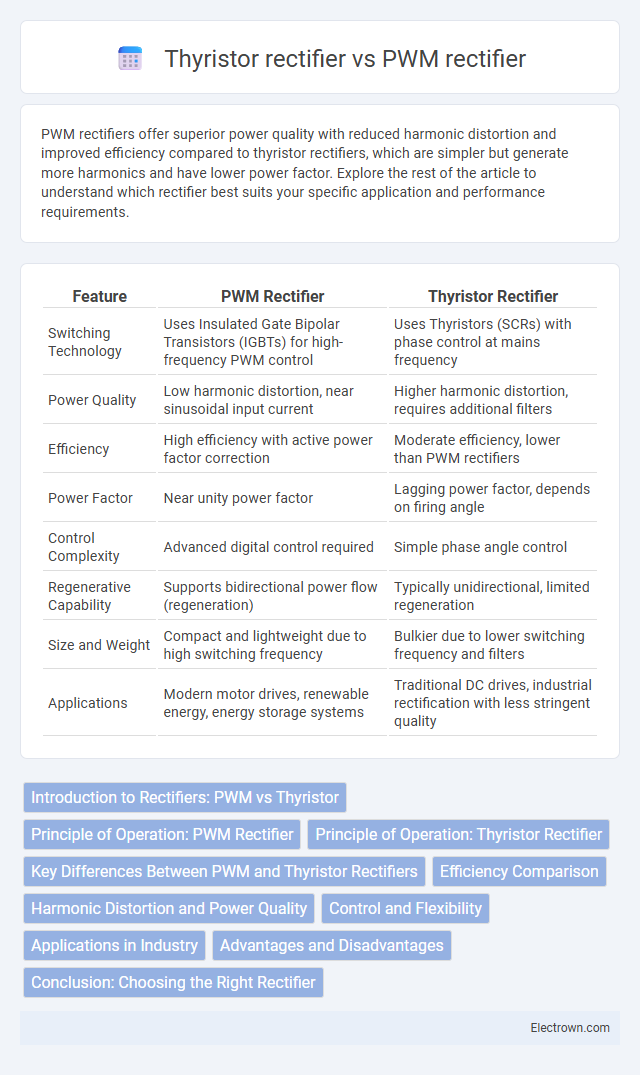

Table of Comparison

| Feature | PWM Rectifier | Thyristor Rectifier |

|---|---|---|

| Switching Technology | Uses Insulated Gate Bipolar Transistors (IGBTs) for high-frequency PWM control | Uses Thyristors (SCRs) with phase control at mains frequency |

| Power Quality | Low harmonic distortion, near sinusoidal input current | Higher harmonic distortion, requires additional filters |

| Efficiency | High efficiency with active power factor correction | Moderate efficiency, lower than PWM rectifiers |

| Power Factor | Near unity power factor | Lagging power factor, depends on firing angle |

| Control Complexity | Advanced digital control required | Simple phase angle control |

| Regenerative Capability | Supports bidirectional power flow (regeneration) | Typically unidirectional, limited regeneration |

| Size and Weight | Compact and lightweight due to high switching frequency | Bulkier due to lower switching frequency and filters |

| Applications | Modern motor drives, renewable energy, energy storage systems | Traditional DC drives, industrial rectification with less stringent quality |

Introduction to Rectifiers: PWM vs Thyristor

PWM rectifiers use pulse-width modulation to efficiently convert AC to DC with precise control over output voltage and current, minimizing harmonic distortion and improving power factor. Thyristor rectifiers rely on controlled semiconducting devices to regulate output but generally produce higher harmonic distortion and require complex filtering. Your choice between PWM and thyristor rectifiers impacts energy efficiency, system performance, and maintenance requirements in industrial applications.

Principle of Operation: PWM Rectifier

A PWM rectifier operates by converting AC to DC through rapid switching of power semiconductor devices, typically IGBTs, controlled by pulse-width modulation signals to regulate output voltage and current precisely. This method allows bidirectional power flow and achieves near-unity power factor by continuously adjusting the duty cycle to match the input waveform. Your system benefits from reduced harmonic distortion and improved efficiency compared to conventional thyristor rectifiers, which rely on phase angle control.

Principle of Operation: Thyristor Rectifier

Thyristor rectifiers convert AC to DC by controlling the conduction angle of thyristors, allowing precise regulation of output voltage through phase control. This phase-controlled rectification modulates the timing of current pulses, enabling efficient power conversion in high-voltage and high-current applications. Your choice of a thyristor rectifier ensures robust operation with controlled DC output suitable for industrial drives and power systems.

Key Differences Between PWM and Thyristor Rectifiers

PWM rectifiers offer superior power factor correction and lower harmonic distortion compared to thyristor rectifiers, which typically produce higher reactive power demand and harmonic levels. Thyristor rectifiers operate with controlled conduction angles, enabling robust performance under high voltage and current conditions but resulting in less efficient voltage regulation. PWM rectifiers utilize fast-switching semiconductors for precise control of input current waveform, improving electrical efficiency and reducing electromagnetic interference in industrial applications.

Efficiency Comparison

PWM rectifiers offer higher efficiency than thyristor rectifiers by significantly reducing harmonic distortion and improving power factor, typically achieving efficiency levels above 95%. Thyristor rectifiers, while robust and cost-effective, often operate with lower efficiency due to inherent switching losses and increased reactive power consumption. Your choice of rectifier impacts overall energy savings, with PWM rectifiers providing superior performance in applications demanding energy efficiency and power quality.

Harmonic Distortion and Power Quality

PWM rectifiers significantly reduce harmonic distortion by utilizing high-frequency switching techniques, resulting in superior power quality with lower total harmonic distortion (THD) typically under 5%. Thyristor rectifiers, in contrast, generate higher harmonic currents due to their phase-controlled operation, often causing THD levels above 30%, which can degrade power quality and necessitate additional filtering. Improved power factor and reduced waveform distortion of PWM rectifiers lead to enhanced efficiency and compliance with stringent grid standards compared to traditional thyristor-based systems.

Control and Flexibility

PWM rectifiers offer superior control and flexibility by enabling precise regulation of output voltage and current through fast-switching semiconductor devices, allowing bidirectional power flow and reduced harmonic distortion. Thyristor rectifiers rely on phase angle control, restricting their ability to finely adjust voltage and current, resulting in less dynamic response and limited bidirectional operation. The advanced modulation techniques in PWM rectifiers enhance power factor correction and harmonics mitigation, making them ideal for modern, demanding applications.

Applications in Industry

PWM rectifiers are widely used in industries requiring precise control of power quality and bidirectional energy flow, such as renewable energy systems, electric vehicle charging stations, and motor drives. Thyristor rectifiers remain prevalent in heavy industrial applications like steel plants, large-scale DC motor drives, and high-power AC-to-DC conversion where robustness and high current handling are critical. The choice between PWM and thyristor rectifiers depends on the need for efficiency, harmonic distortion levels, and the specific dynamics of industrial processes.

Advantages and Disadvantages

PWM rectifiers offer superior power factor correction and lower harmonic distortion compared to thyristor rectifiers, enhancing the quality of electrical systems. Thyristor rectifiers, while more robust and cost-effective, suffer from higher harmonic generation and limited efficiency under varying load conditions. Your choice between these rectifiers should consider the balance between initial investment, performance requirements, and system complexity.

Conclusion: Choosing the Right Rectifier

PWM rectifiers offer higher efficiency, better power factor correction, and reduced harmonic distortion compared to thyristor rectifiers, making them ideal for applications requiring precise control and energy savings. Thyristor rectifiers, while more robust and cost-effective for high-power industrial uses, often result in higher harmonic emissions and lower overall efficiency. Your choice depends on balancing efficiency needs, power quality requirements, and budget constraints specific to your application.

pwm rectifier vs thyristor rectifier Infographic

electrown.com

electrown.com